With the plexiglass canopy parts mostly under control, I’ve moved back to finishing the canopy frame and skins.

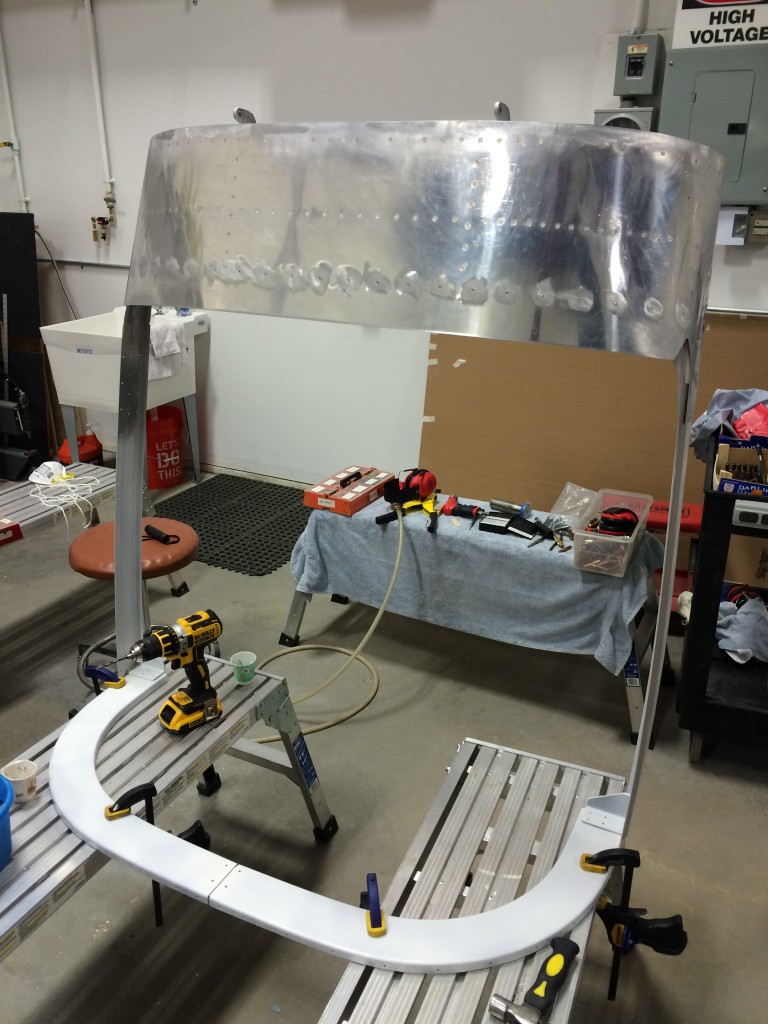

First off, I finished match-drilling the rear canopy frame. Nothing too difficult here.

I pulled the frame off the fuselage then deburred, countersunk, primed and riveted everything together. Then, I started on the canopy lift strut attach brackets.

The forward attach points require a lot of tweaking and fitting to fit inside the forward canopy frame. Once match-drilled, they’re tapped to accommodate #10 screws that keep them in place on the frame, and also for the large “knob” that provides an attachment point for the lift struts.

This quality Vermont American tap failed on its second use. I did a little research on where VA’s tools are made, and it seems like their name should really be Vermont Chinese, or Guangdong German, or something that more accurately depicts where the company really resides.

Not that I mind buying cheap Chinese shit tools…I go straight to Harbor Freight when I need a tool that I’m gonna intentionally tear up or modify, only has to last for a few uses, or most importantly, is something that my life won’t depend on.

I’ve been waiting a long time to use these custom-machined canopy strut mounts from Rich Mileika at Machine, Inc. Not only did they save a lot of fabricating time, they look really cool too.

Locating the right position for these mounts was the easy part; getting them screwed into place was harder. Once the mounts were match-drilled to the canopy rails for #10 screws, I had to get up, under and behind the canopy rails to get the locknuts in place.

I didn’t have any wrenches that would get into this spot, so I improvised…I took a cheap 11/32″ socket, hammered it onto a piece of 1/4″ aluminum fuel tubing, and bent the tube such that I could get the socket around the canopy rail. As ugly as it is, it worked like a champ. After I used it to get the mounts installed, I pulled the socket off and reattached it with JB Weld – probably won’t be the last time I’ll need to use this device.

Here’s the canopy frame with the lift struts attached. Cool.

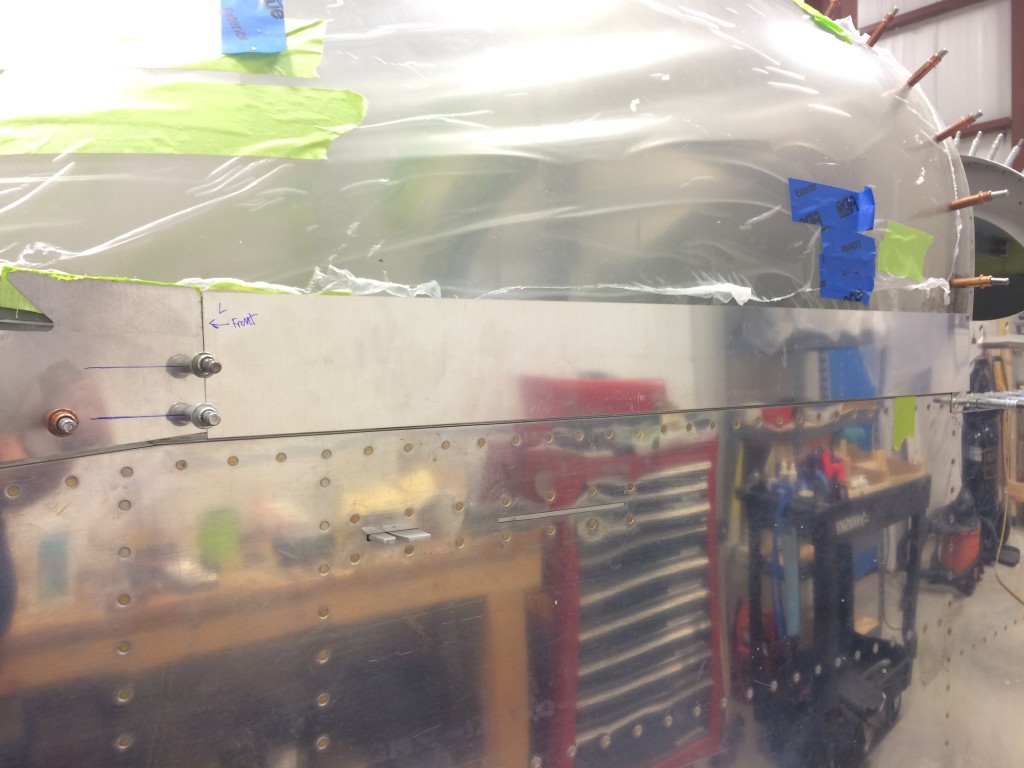

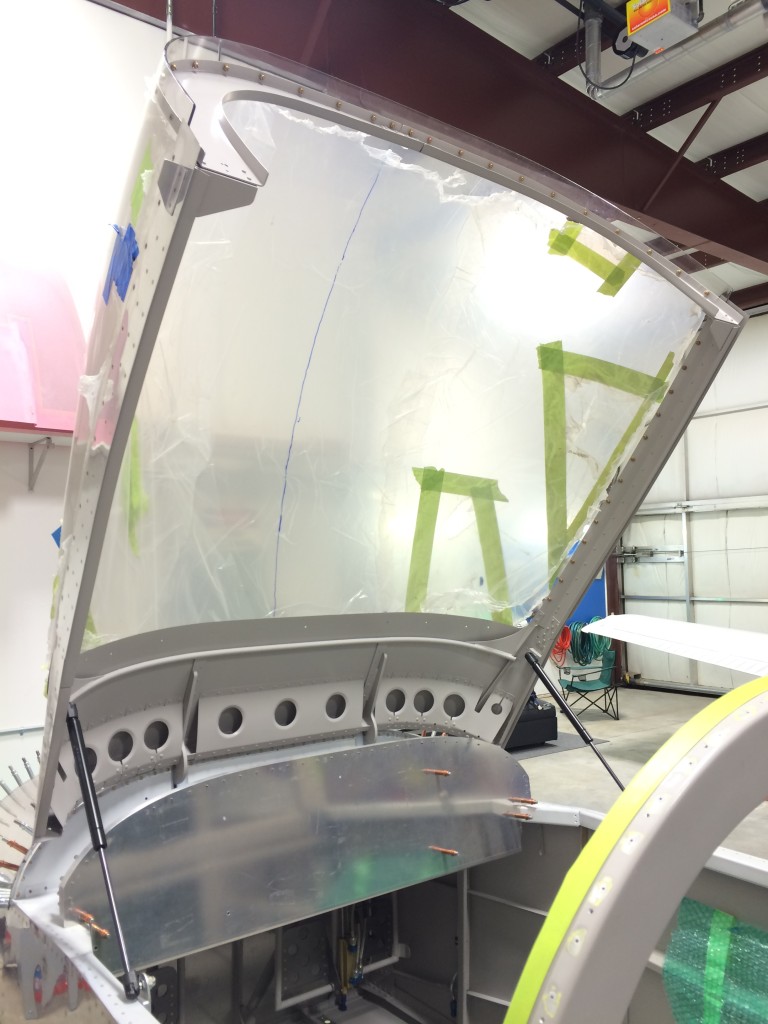

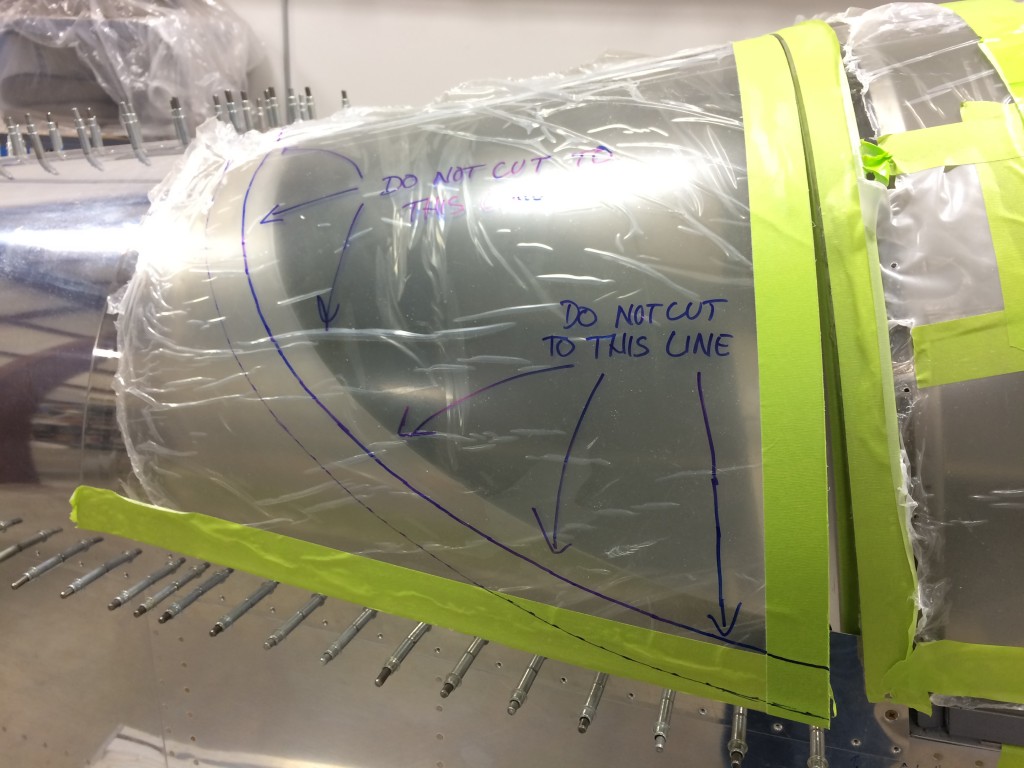

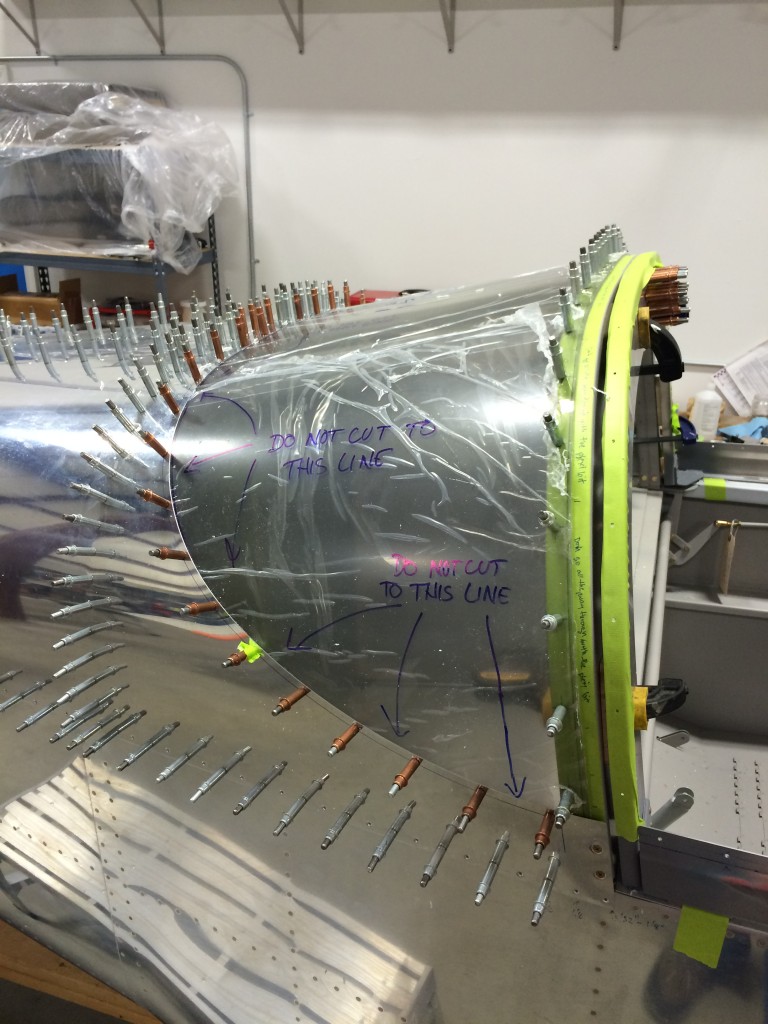

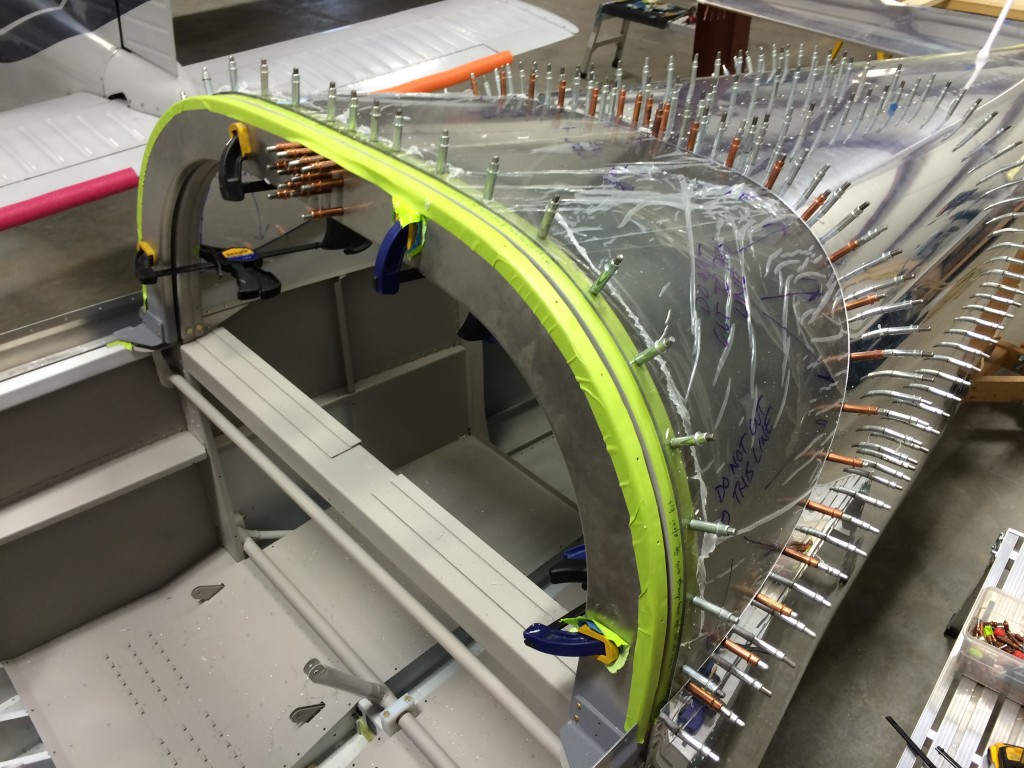

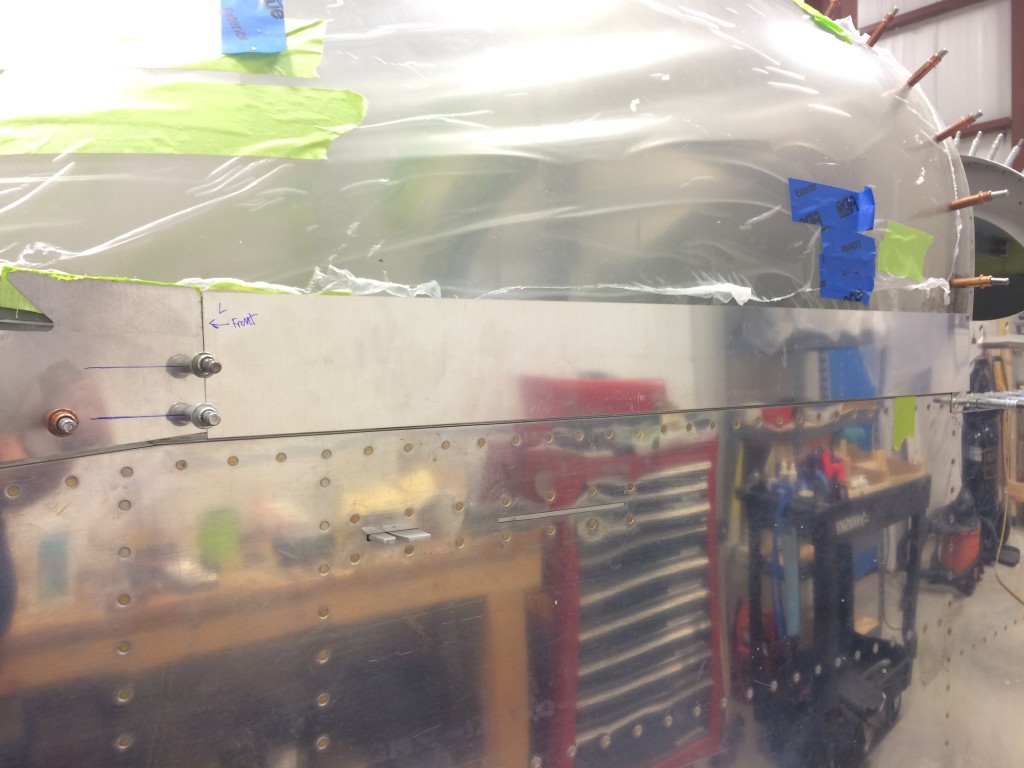

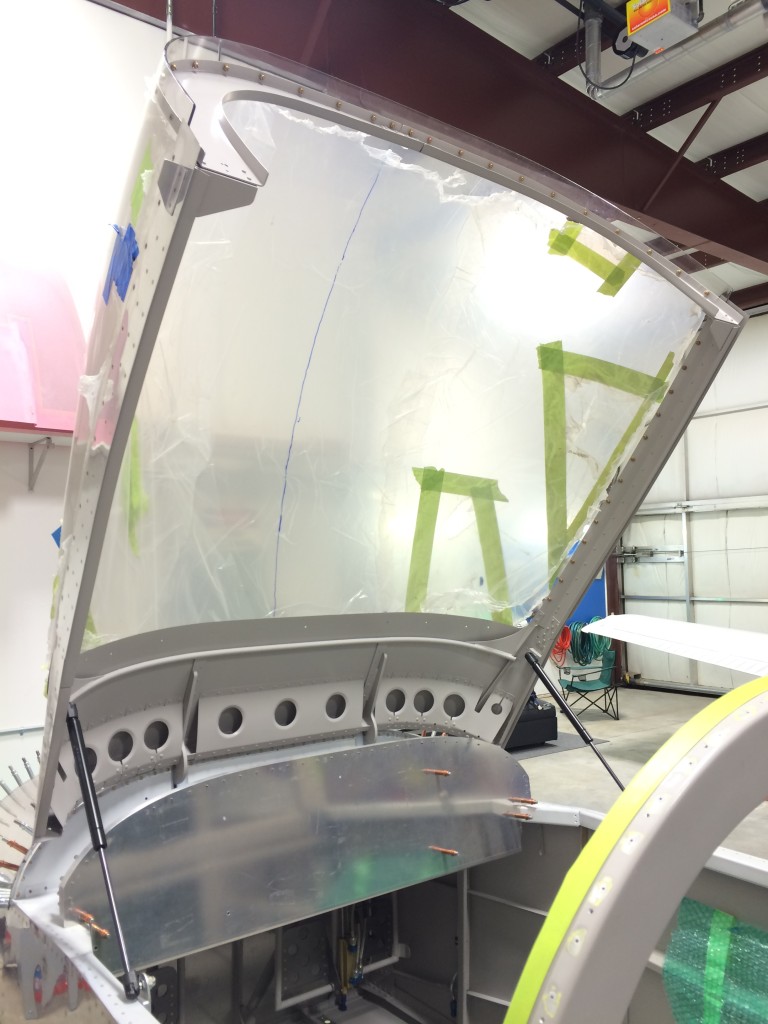

I put the canopy back on the frame…it’s time to start fitting the side skirts.

The challenge here is getting the skirts clamped in place. Some builders have made some really spiffy clamps out of aluminum C-channel to slip under the skins and hold them in place, but I didn’t have the patience to do that.

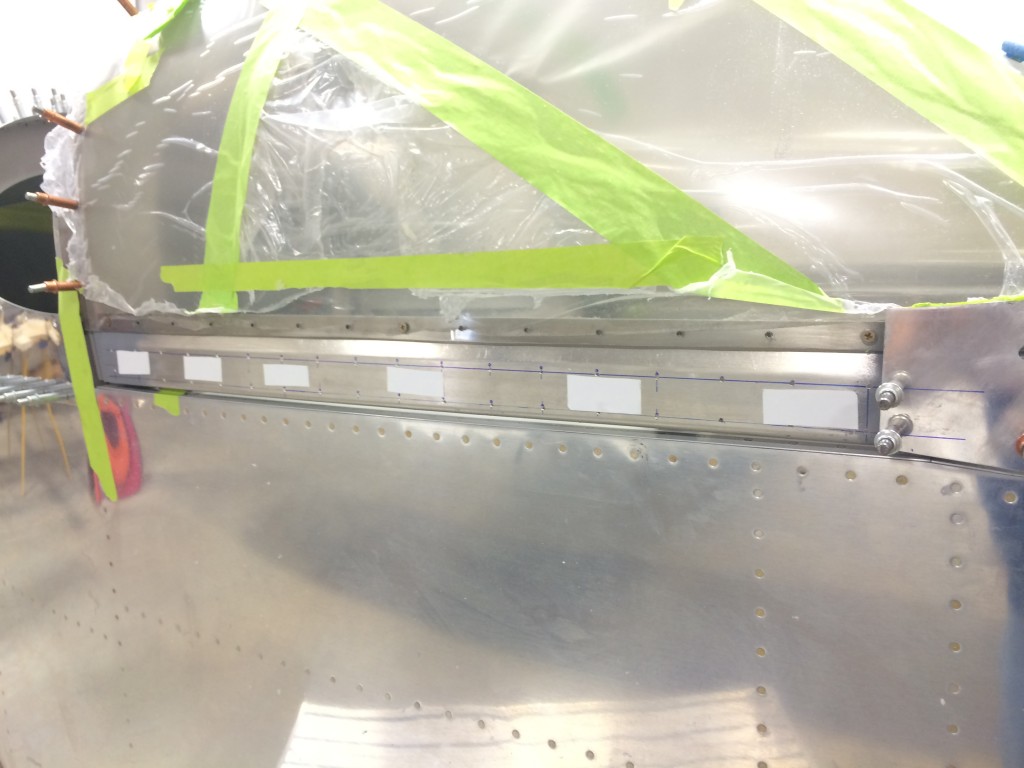

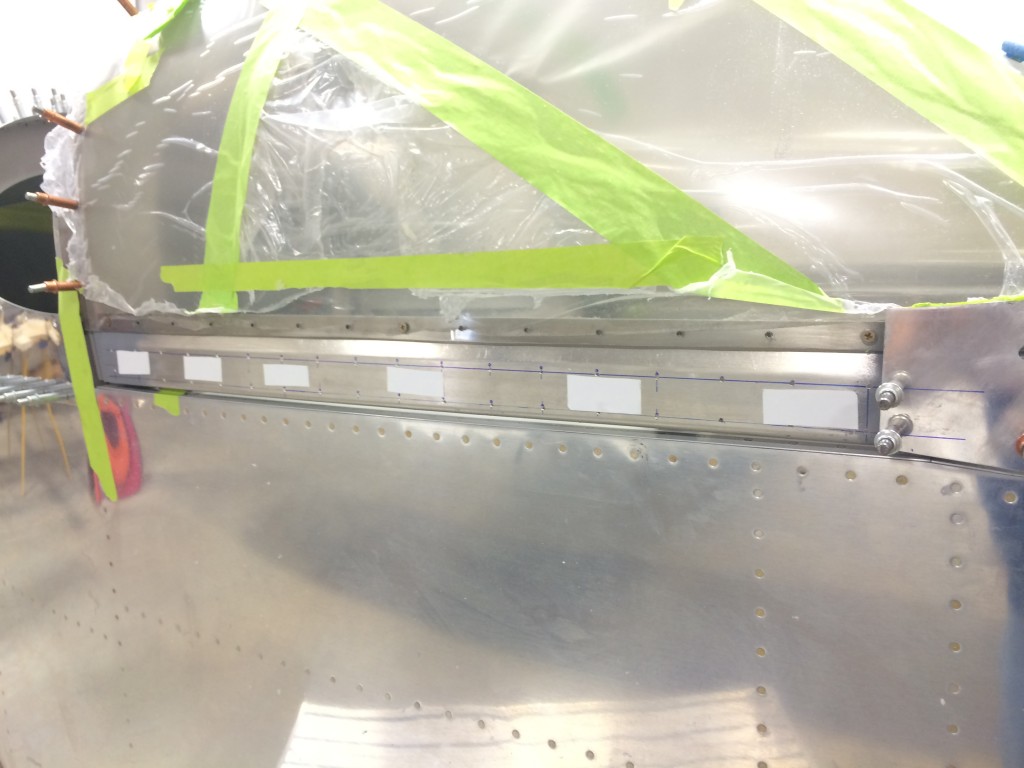

Instead, I just used some 3M two-sided tape to hold the skirts in the correct position until I could raise the canopy and clamp them with regular Pony clamps. In the pic above you can see that I’ve already laid out and pre-drilled the side skirt rivet holes.

Lookin’ good prior to drilling…

And after several minutes sitting inside the closed canopy (cool!) with an air drill, the side skirts were match-drilled to the frame. Not much left at this point except to countersink the frame holes and debur/dimple the skirts.

One of the things I wasn’t too happy about was the fit of the forward canopy skin to the forward fuselage skin – they just didn’t quite line up.

As I tend to do, I threw money at the problem. I made a trip to Harbor Freight and bought a metal shrinking/stretching tool set. After practicing on some scrap sheet metal, I used the metal shrinker on the leading edge of the canopy skin.

The results were better than I expected…the metal shrinker really closed up some of the gaps between the canopy skin and forward fuse. Unfortunately, I didn’t get a picture of the fit with the canopy installed, so you’ll just have to trust me.

One slight downside to the metal shrinker is that it leaves small toothmarks on the metal when it’s used – but a scotchbrite pad on the die grinder made quick work of them.

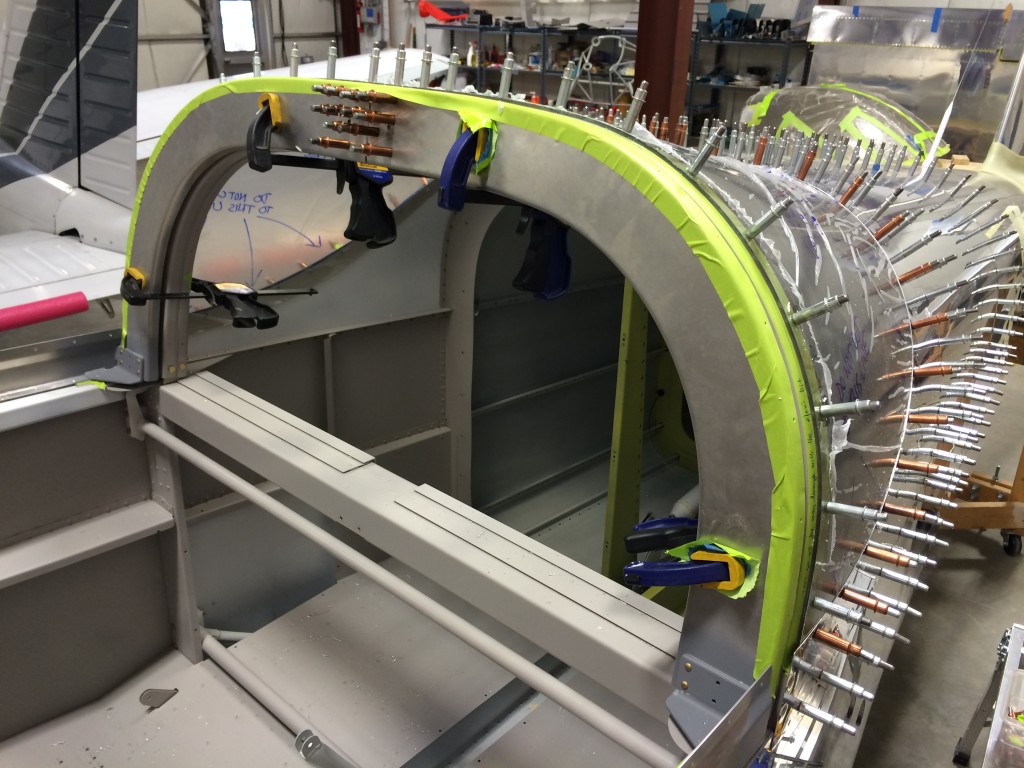

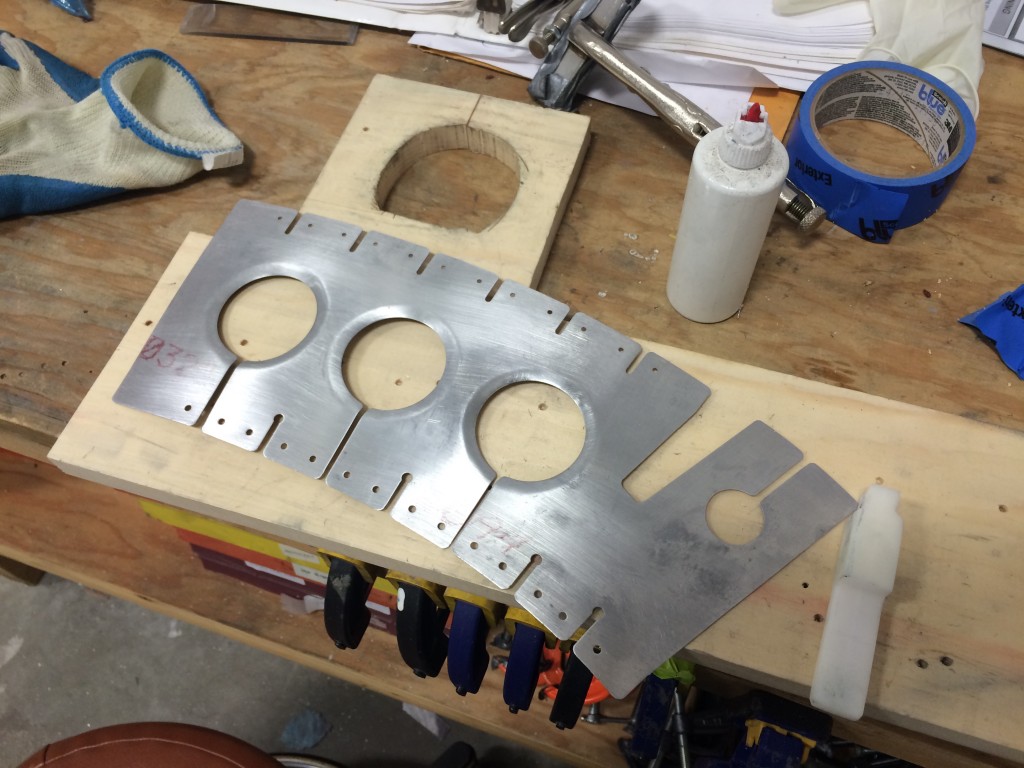

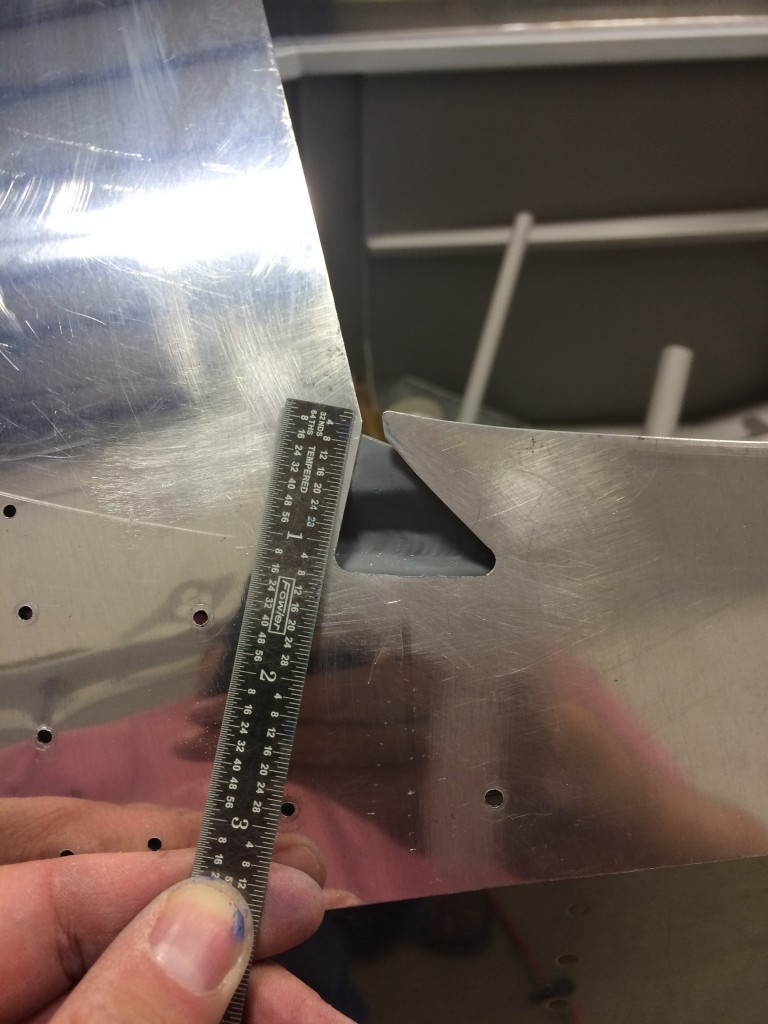

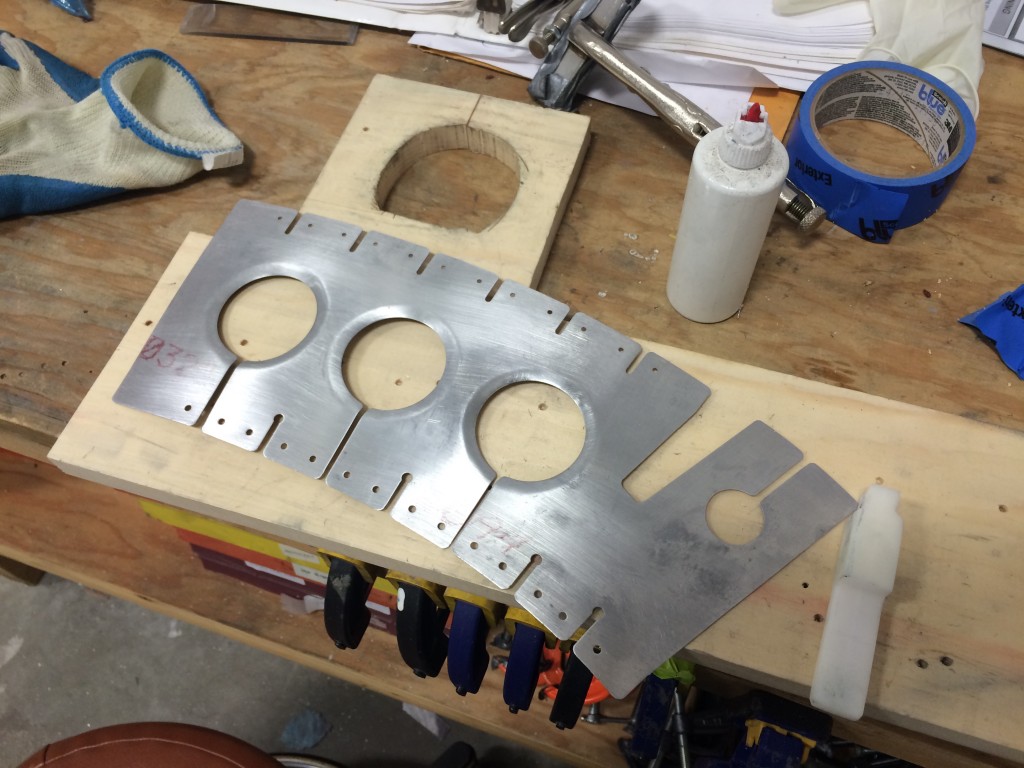

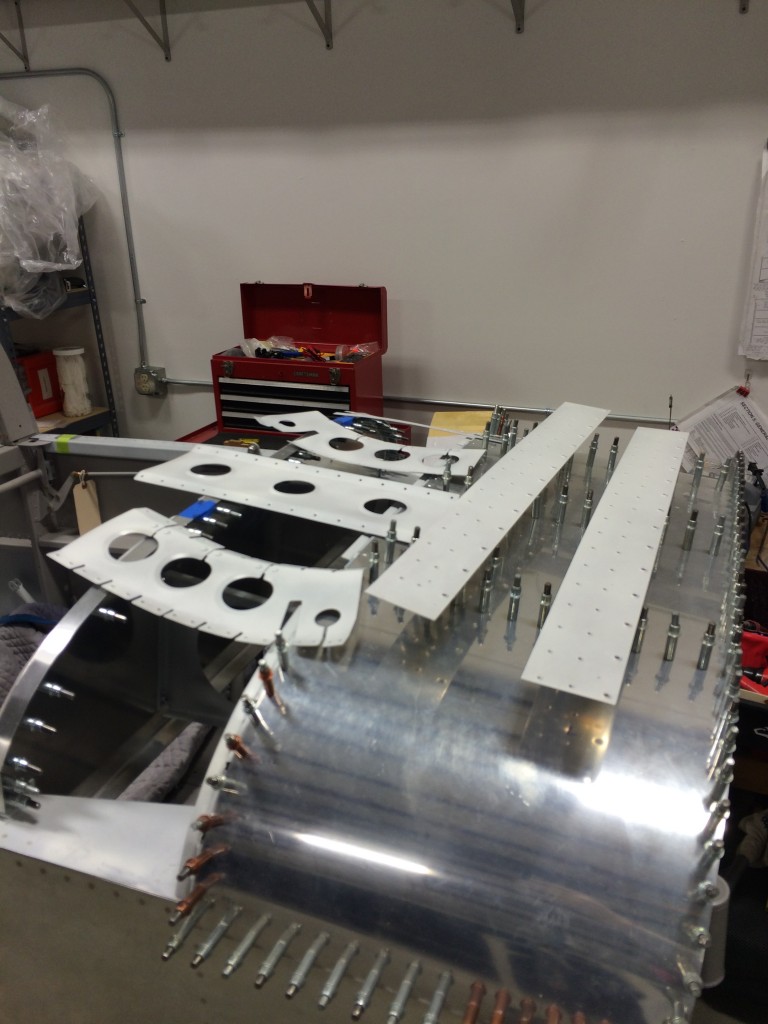

Like most tip-up builders, I chose to install the optional canopy reinforcement kit. Otherwise the canopy frame is pretty floppy even when the canopy bubble is installed. There are a lot of holes and slots that need deburring, fortunately there really isn’t much more of this to do on the project.

The plans call for the three large lightening holes to be “flanged”, or have the edges of the holes bent slightly to make the metal stiffer. There are lots of way to do this, and I chose the old-fashioned way – a piece of delrin with a slot cut into it, which is used to bend the edge as it’s slid around the inside of the hole.

It’s a pain, because several passes are required to get a good bend – but in the end, the flanges came out great.

Here are the stiffeners drilled to the canopy frame.

There are small tabs to be fitted and drilled to the stiffeners…not hard to do.

…and they’re done.

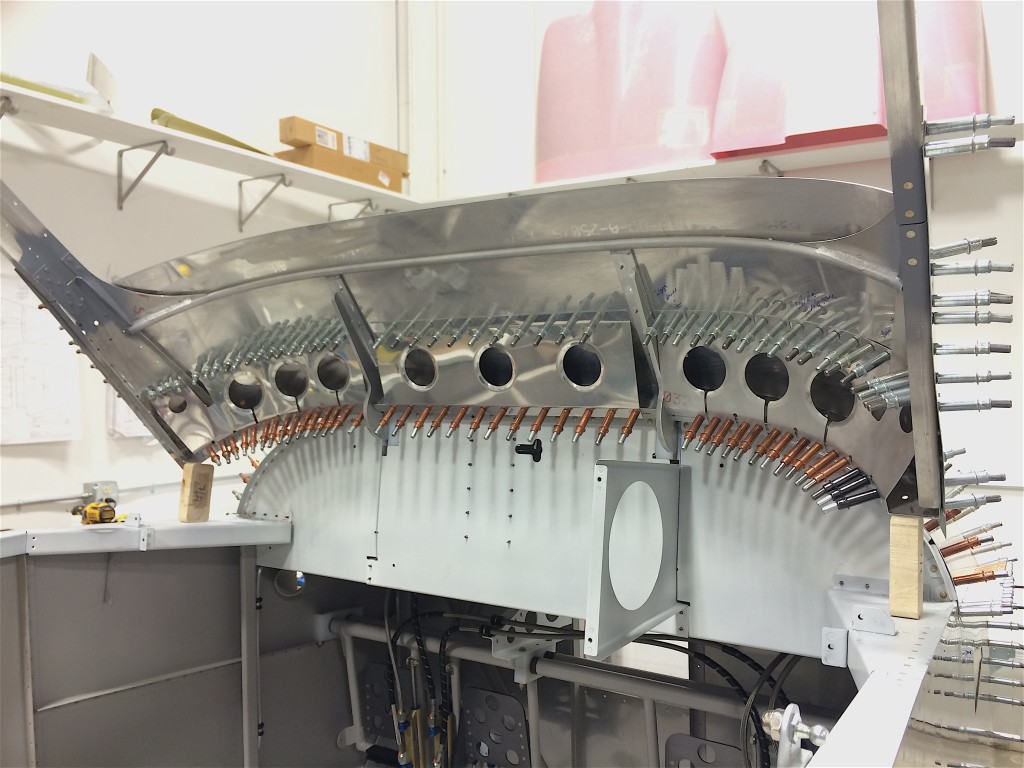

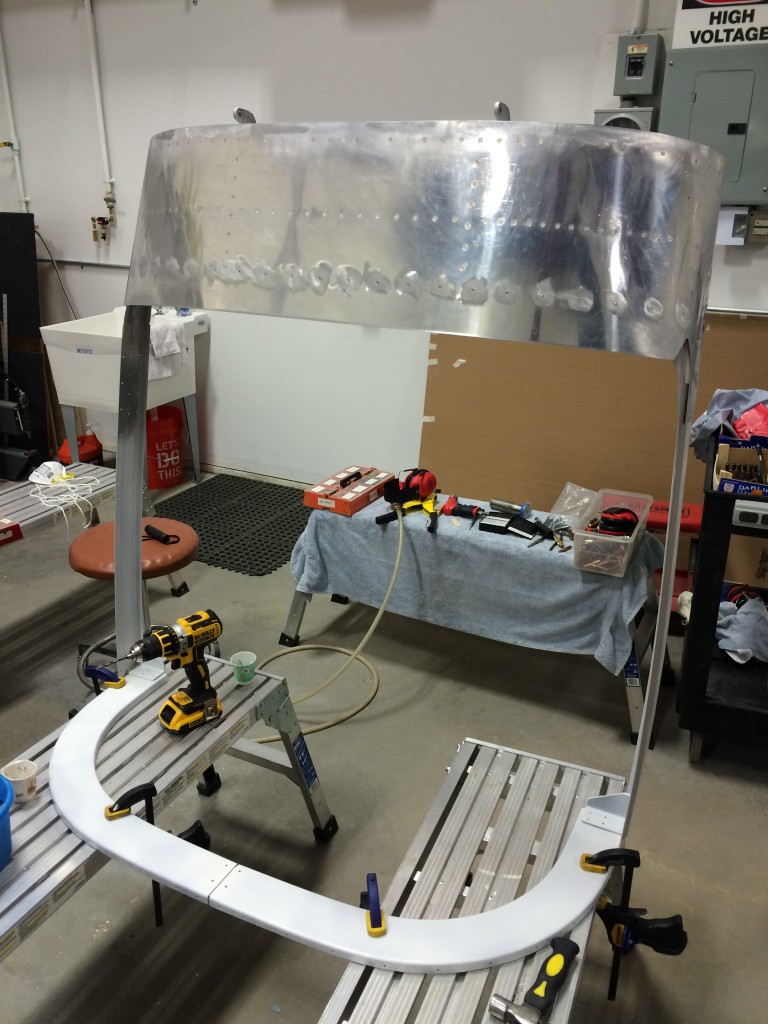

At long last, it’s time to prime the canopy skins and stiffeners, and rivet them to the frame.

Blecch…priming. I’m glad there isn’t much more to do.

Priming the canopy frame was a pain, but hanging it from the engine stand made things easier.

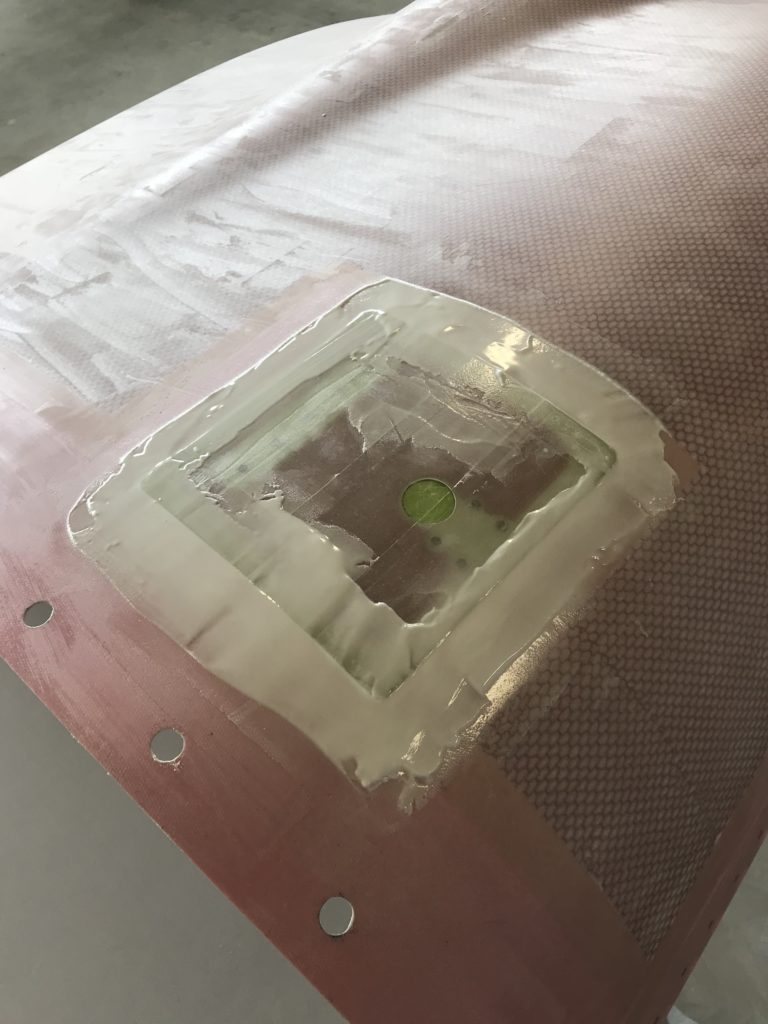

The canopy skin doesn’t fit particularly well on the frame, so I used an epoxy and flox mixture to fill gaps between the skin and frame. Once it cured, Bob DiMeo and I riveted the skins on. The epoxy/flox mixture worked pretty well – there aren’t the dimples in the canopy skin that I’ve seen on other projects.

More riveting fun, this time after several pop rivets have been pulled. The pop riveter takes some manual effort to use, and my forearms are aching.

Unfortunately I neglected to take any pictures while I painted the canopy frame interior with JetFlex WR. This took a long time…I did a lot of repainting to get a good finish, and it was a real pain.

After the JetFlex dried, I masked off the glareshield for surface prep, priming and painting.

I used a good flat black automotive enamel to paint the glareshied, and it came out very nicely.

I installed the canopy strut pivots…kinda satisfying to do something so simple.

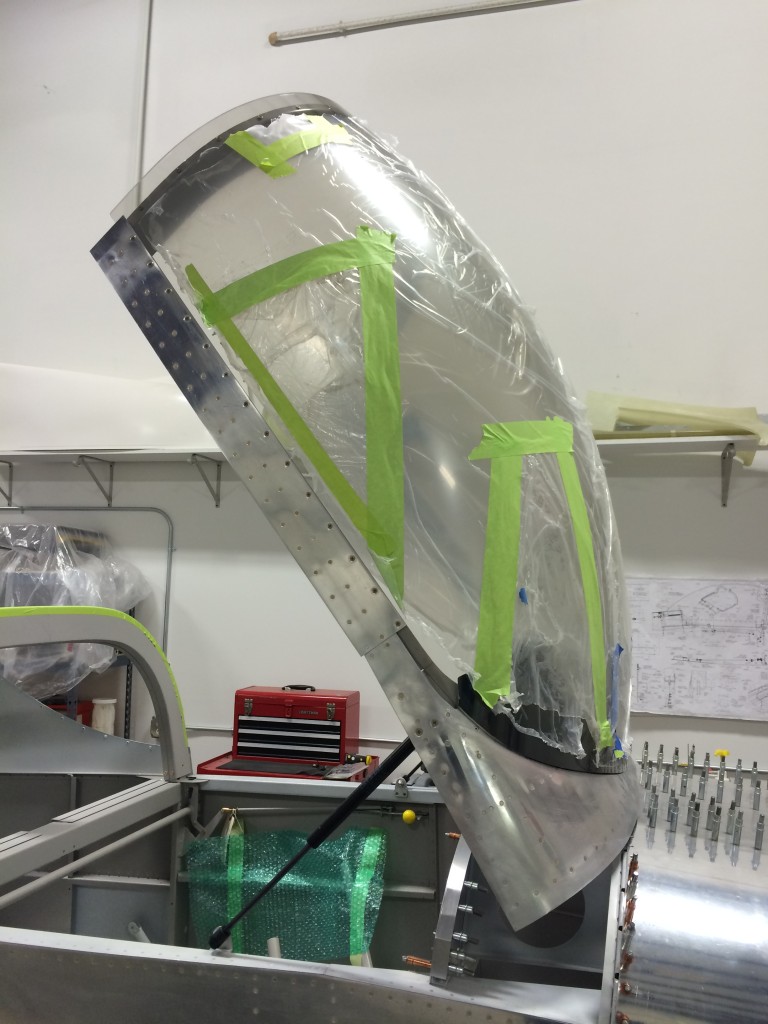

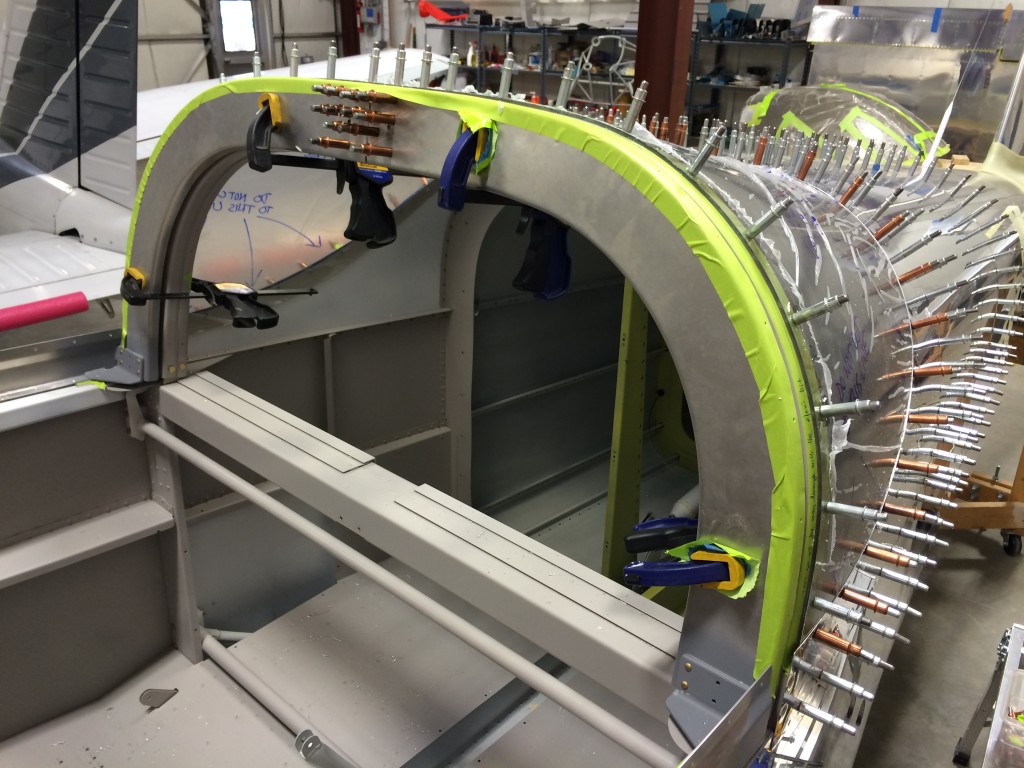

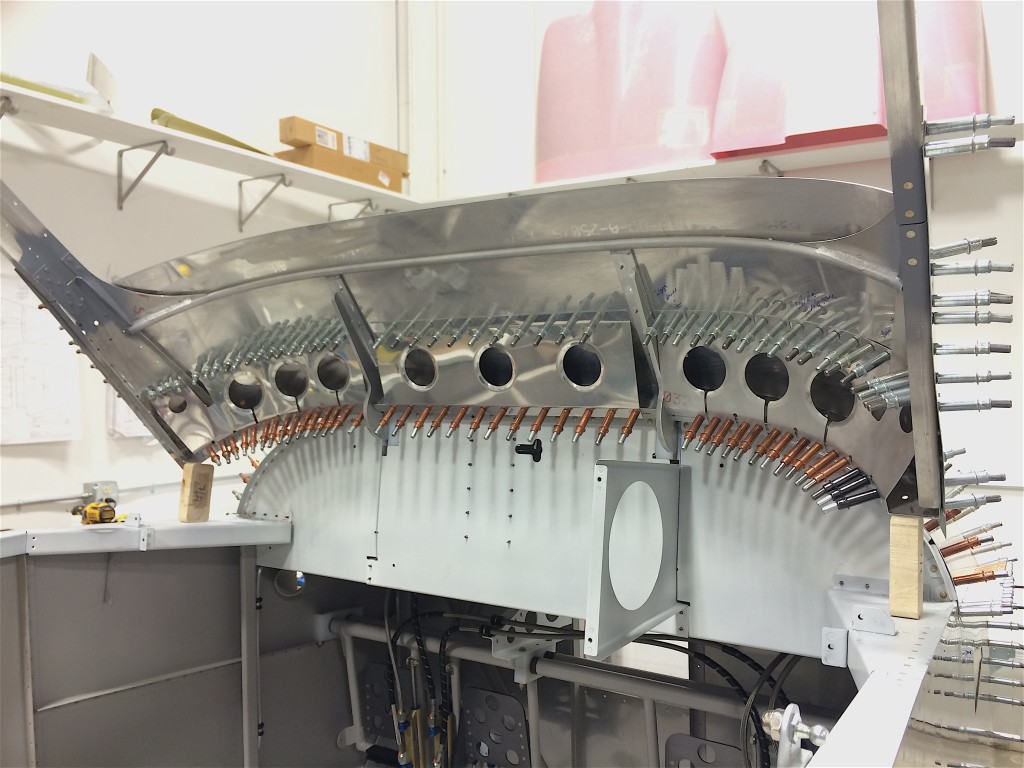

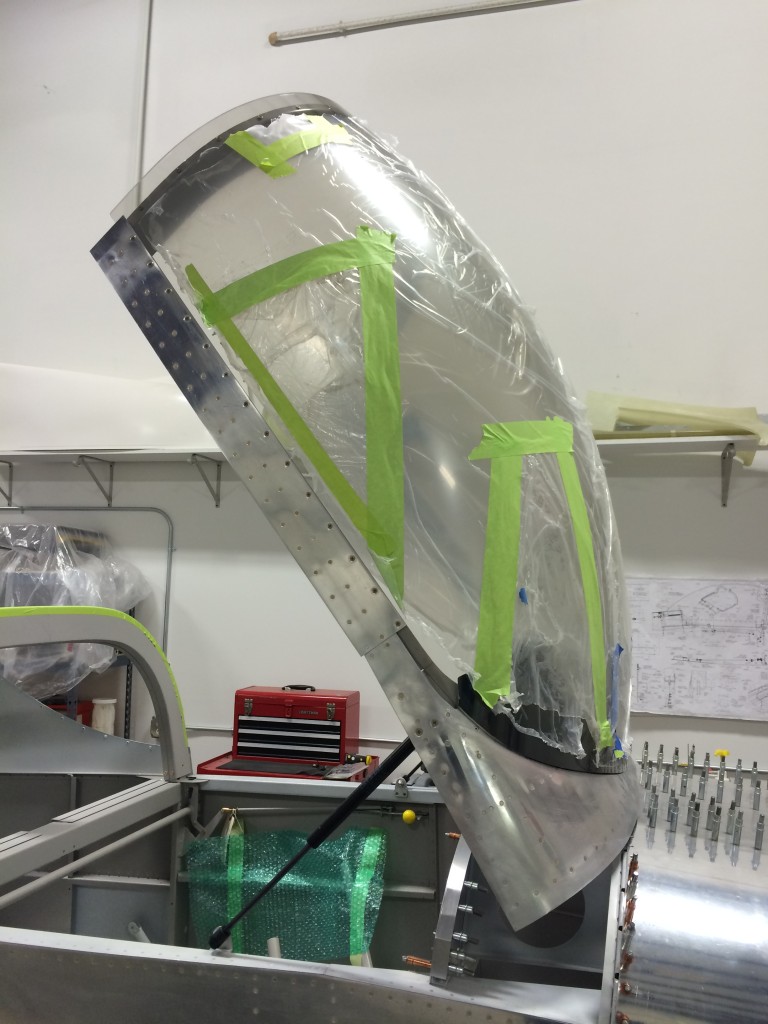

Here’s a bit of visual progress…the painted canopy frame with the canopy installed. Very cool!

Another picture? Sure, why not…

The last bit of work was installing the aft canopy latches.

I don’t have much to add to the instructions, except that I had to do some improvising to keep the latch fingers clamped in place while I match-drilled them. A piece of spruce filled the bill.

I also clamped and drilled the upper canopy safety latch block to the canopy frame. Unfortunately, I forgot to take any pictures so you’ll have to use your imagination. I deviated from the plans a little and installed a spring beneath the washer and cotter pin that hold the handle in place. Once the block wears a bit and the handle turns more freely, the spring will pull the handle tight against the frame and keep it from inadvertently rotating to the close position, with the unfortunate effect of locking the canopy from the inside. It’s happened to other builders, and I’d like to avoid all the gyrations they had to endure to get the handle unlatched.

Most tip-up builders don’t go to the trouble of installing the canopy emergency release because (a) no one has ever bailed out of an RV-7, and (b) the release handle takes up valuable real estate on the instrument panel.

I’ve been debating the merits of installing the release for a few years, and finally came to the conclusion that I’d rather have it and not need it rather than the other way around. I also want to keep the instrument panel relatively simple, and keeping space for the release handle forced me to do that.

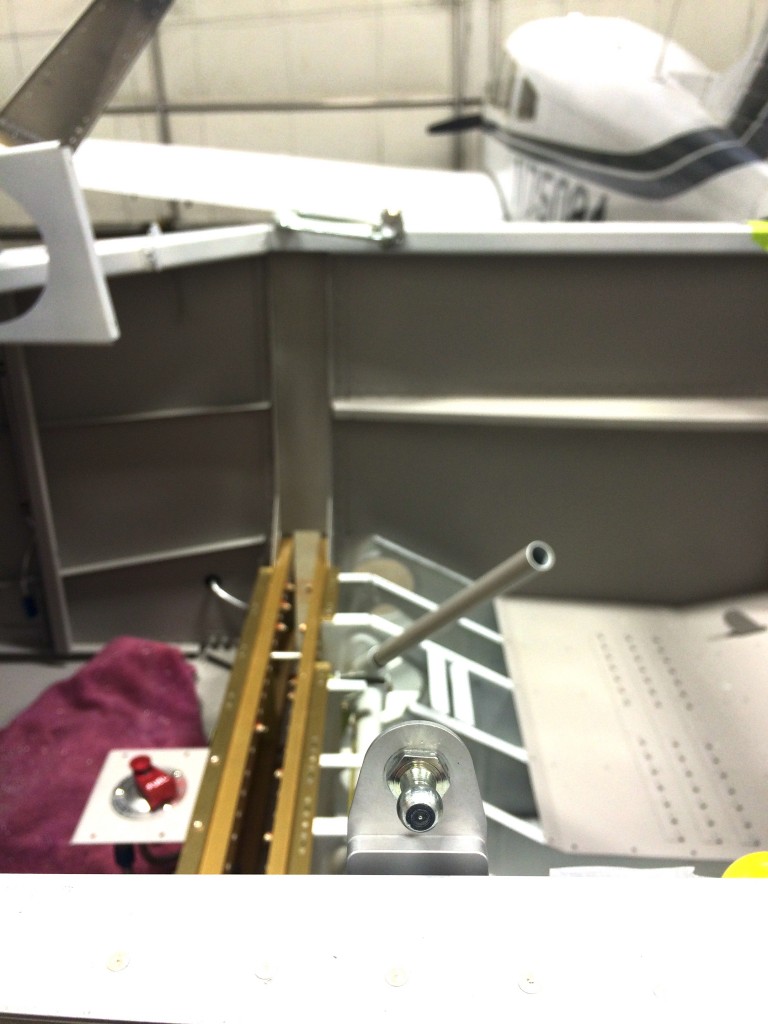

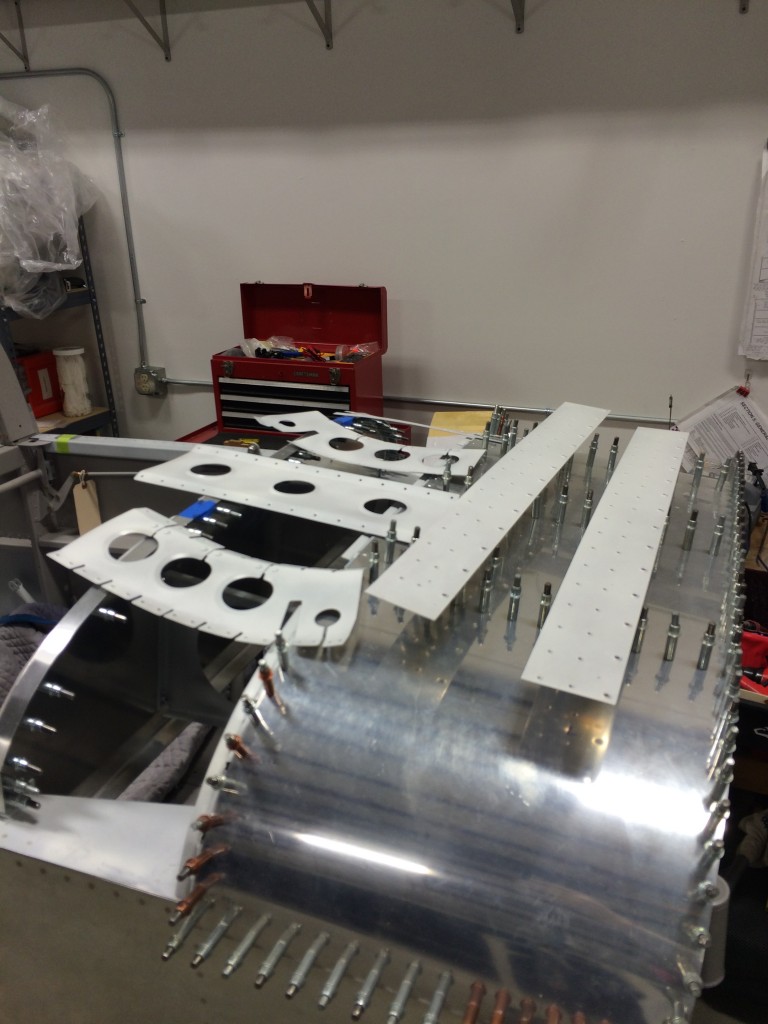

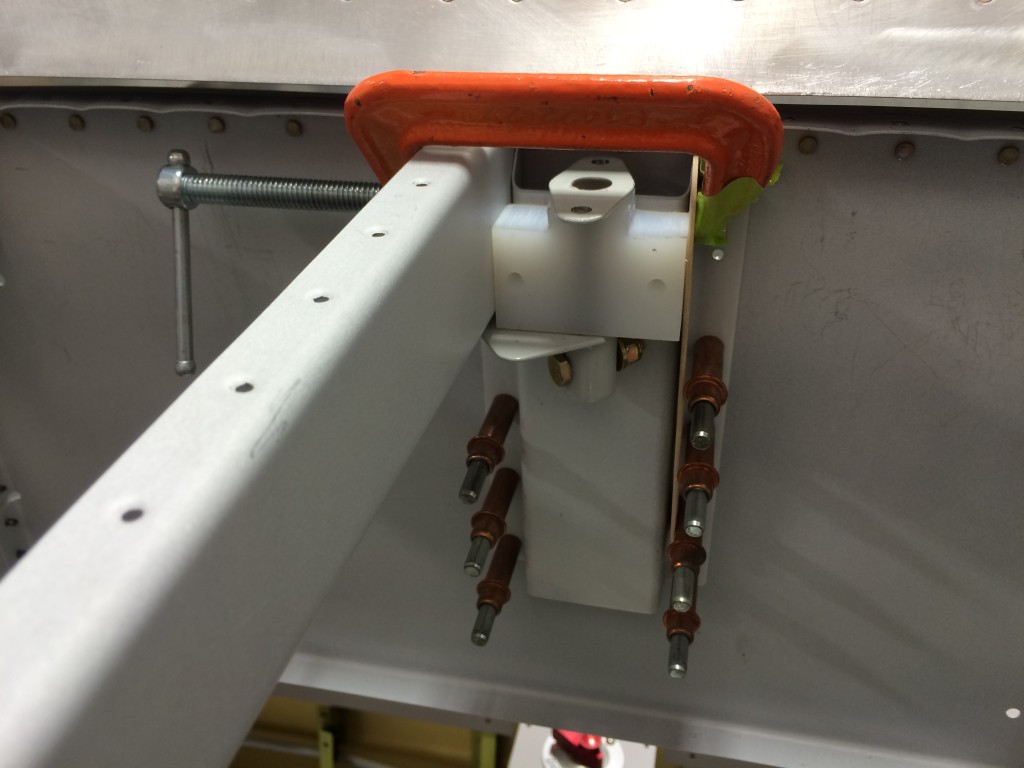

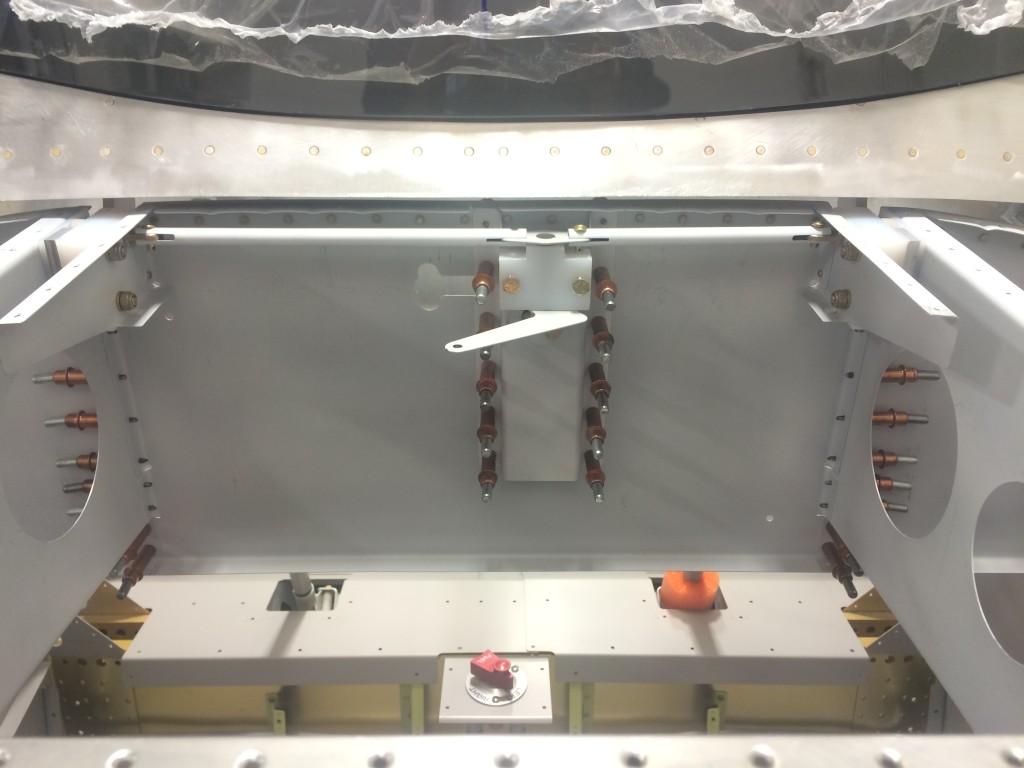

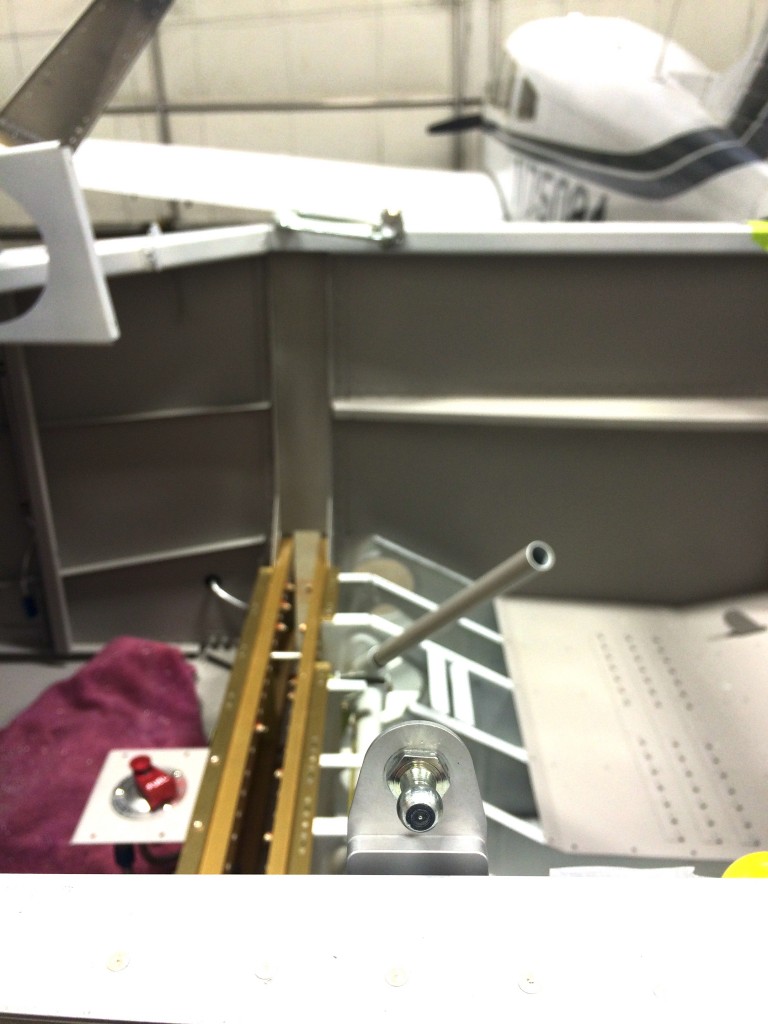

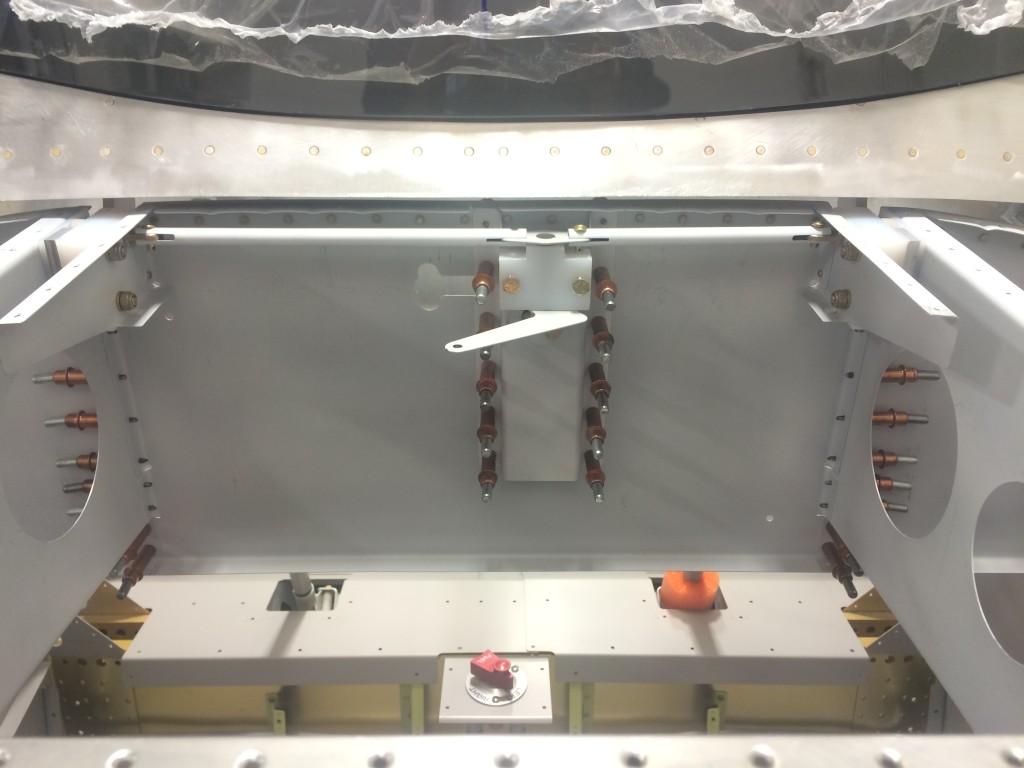

The first step was to drill the release pivot block to the hat section on the subpanel.

With the holes drilled, I installed nutplates to accommodate the attach bolts.

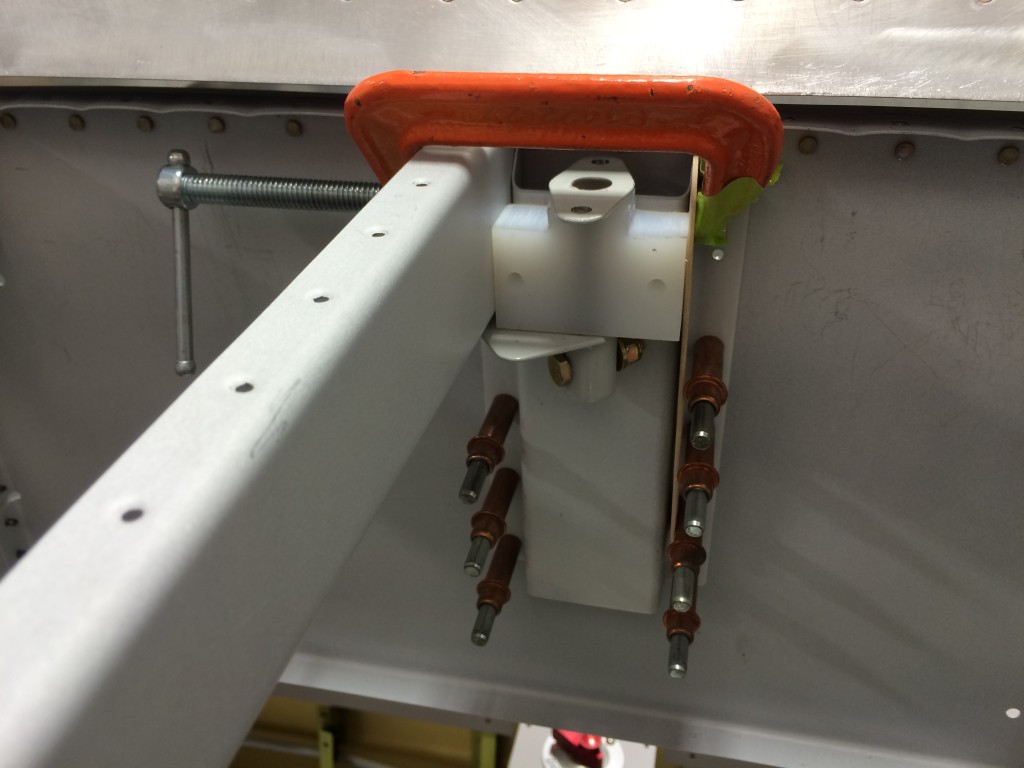

In this picture the pivot block and actuator arm are in place and attached to the canopy hinge pins with steel rods. Actually, the left rod isn’t connected to the actuator because the rod was slightly short even though it was fabricated according to the plans. So…I got to fabricate another one that was 1/16″ shorter.

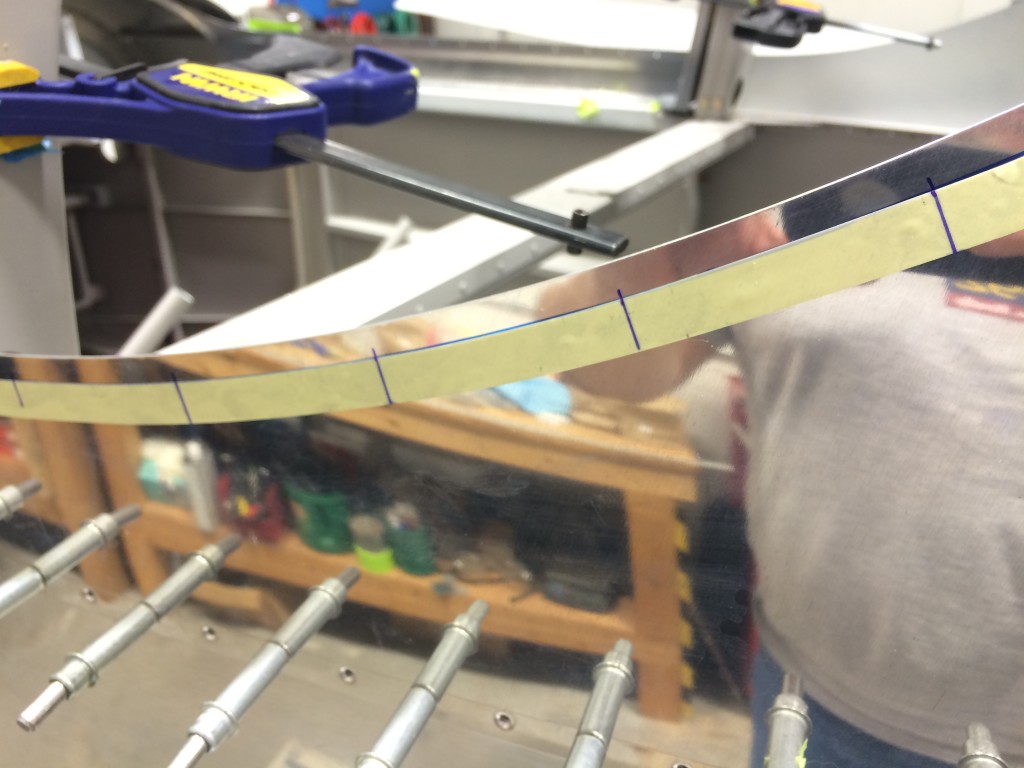

There’s not much to add about fabricating the steel parts, except that the slots in each steel rod that accommodate the actuator and pins are most easily cut with a Dremel tool with a cutoff wheel. Some work with files will still be required, but the Dremel will get 95 percent of the cutting done.

The release mechanism is on the shelf now, and will be reinstalled right before I’m ready to rivet the front fuselage skin in place.

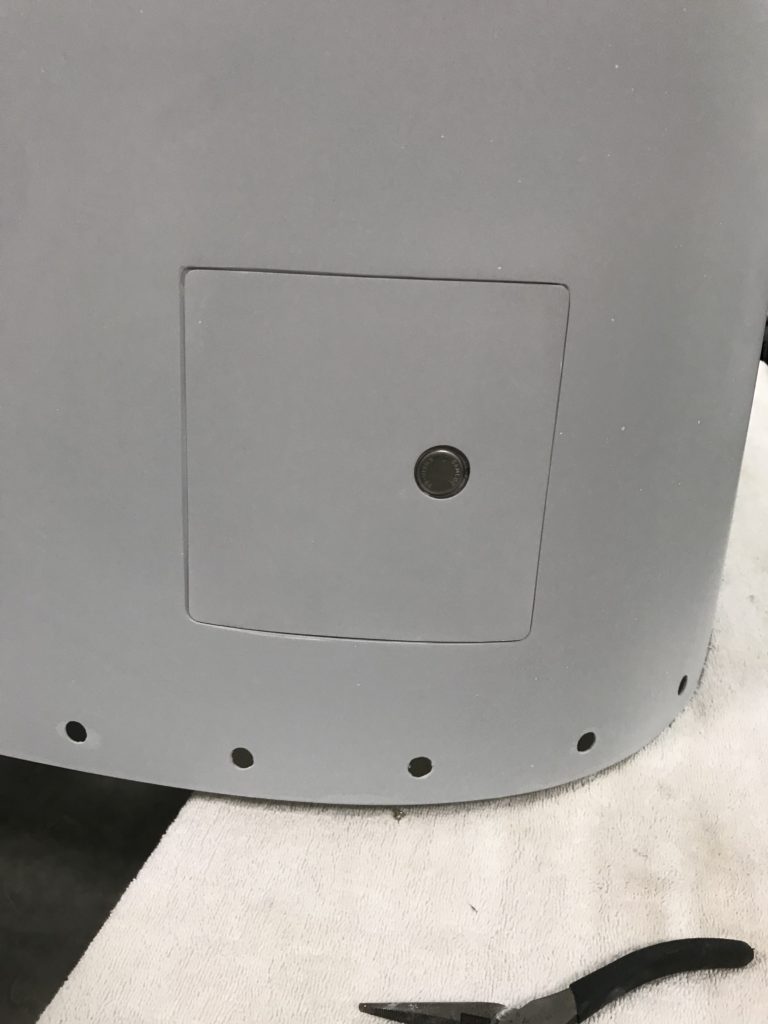

And the cowl pin covers look great…couldn’t be happier with how they came out. They were worth all the work!

And the cowl pin covers look great…couldn’t be happier with how they came out. They were worth all the work! I disassembled the cowl and laid down some heat-reflective adhesive aluminum to help protect against hot spots from the engine. Sorry, no pictures of that!

I disassembled the cowl and laid down some heat-reflective adhesive aluminum to help protect against hot spots from the engine. Sorry, no pictures of that!