One of my side projects over the last several years has been designing and re-designing the instrument panel. This is one area that every new builder likes to jump into right at the beginning of their build, and it’s probably one of the last areas we should worry about because the experimental avionics market changes so quickly.

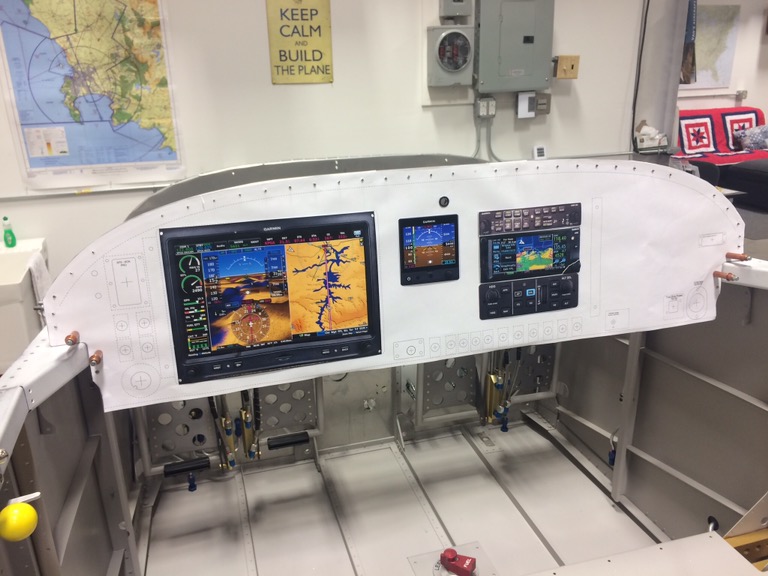

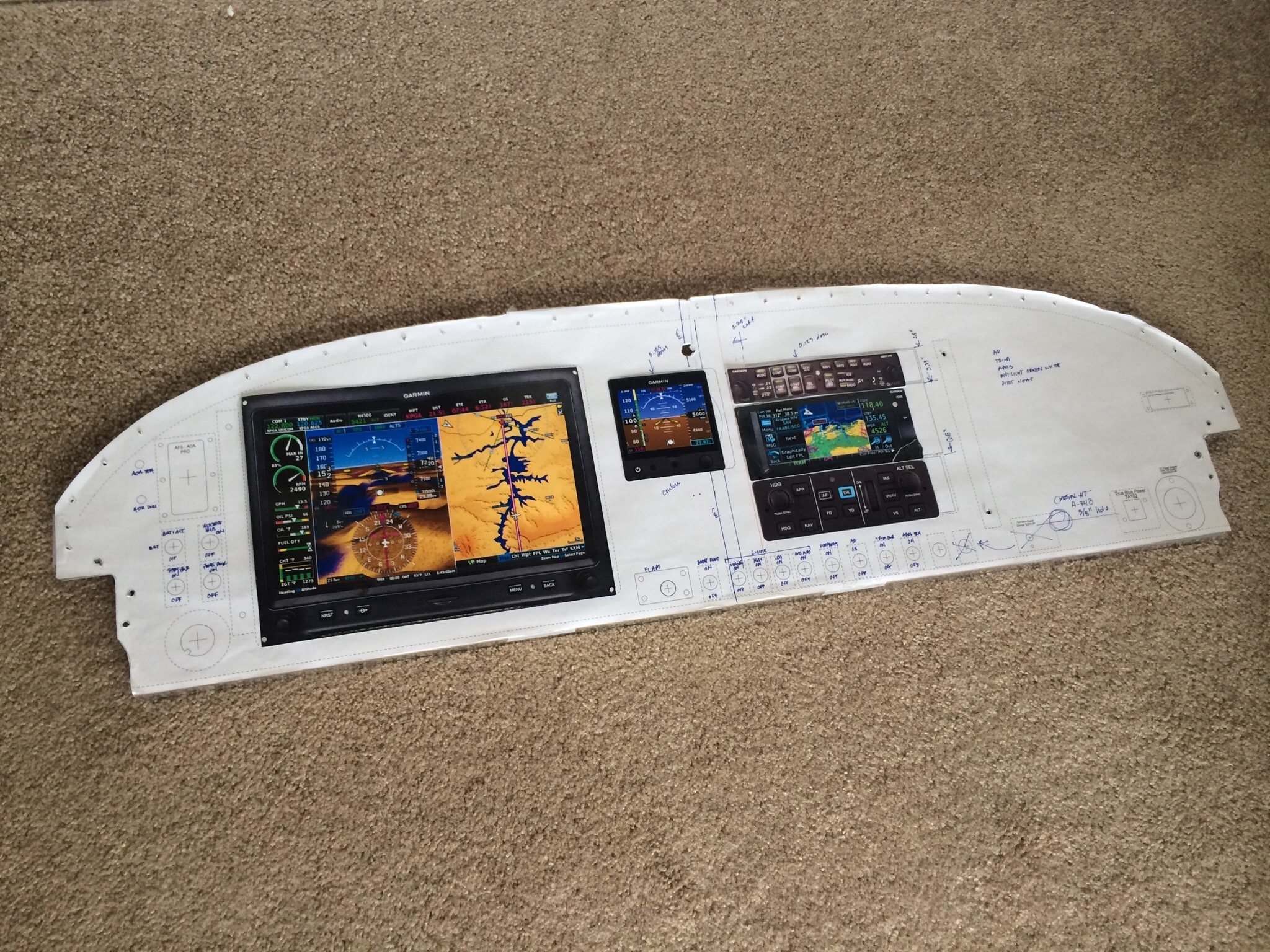

But I’m at the point now where I must make provisions on the instrument panel fo specific avionics, so it’s time to commit to avionics equipage and cut the panel. You can tell by the picture below that I’ve chosen Garmin avionics for just about everything except the Advanced Flight Systems AoA indicator.

I decided early on that I’d have the panel professionally cut so I needed to find a shop that could do the CAD layout and also had the ability to do CNC milling. There are lots of panel design and cutting providers on VAF, but I’d heard good things about Bill Morelli at Up North Aviation in Swanton, Vermont and decided to give him a try. I’m glad I did.

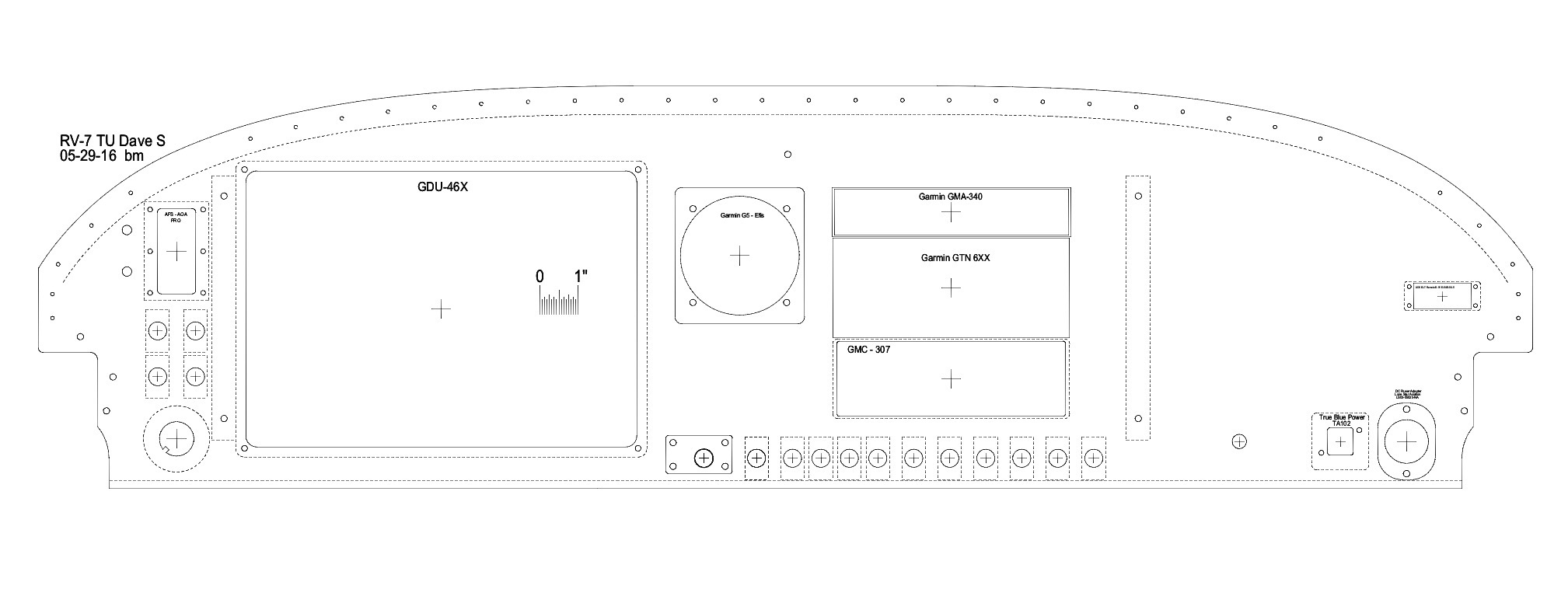

I already had a basic idea of what I wanted in the panel, so I gave my ideas to Bill and he came right back with full-size CAD layout PDFs based on my inputs. For most iterations I’d have Kinkos print out the PDF at full size, cut out the panel from the print, overlay it on the blank aluminum panel, then make adjustments that I sent back to Bill for a new CAD layout. Bill and I went through this cycle many times, and he was extremely patient with all the little tweaks I requested.

The above picture is Bill’s CAD rendering of my final design, and the picture below is the end result after Bill cut my panel.

I’m extremely pleased with how it came out!

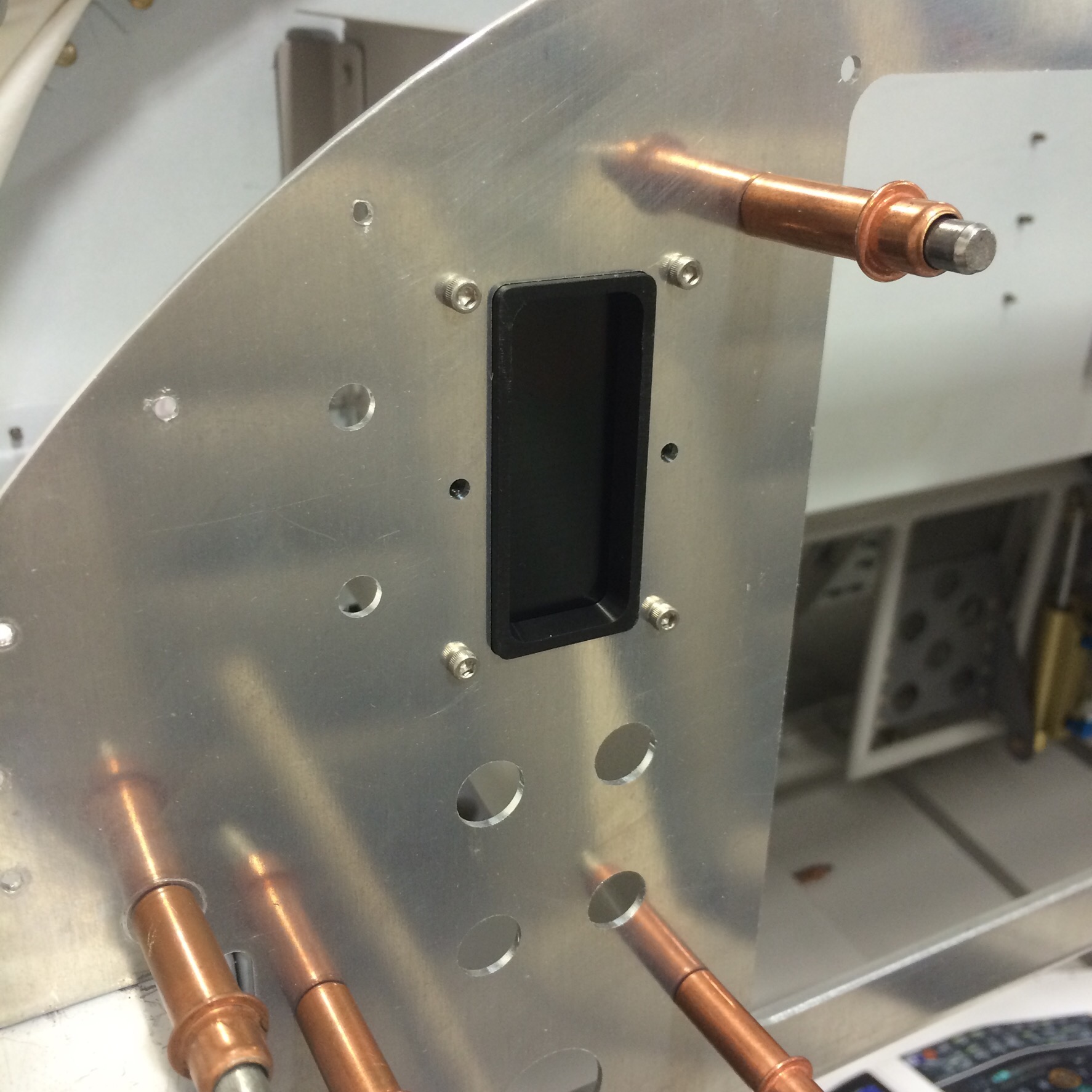

Here’s one example of the quality of Bill’s work. I pulled out the Advanced AoA display head and temporarily attached it to the panel. The fit is practically perfect!

With the panel cut, I’m warming up my frequent-flier rewards card in preparation for big avionics buys at Oshkosh…