I found that all the wiring I’d run between the instrument panel and cockpit center section just wasn’t going to fit in the “tunnel” that covers up wiring, brake lines (for nosedragger RVs) and fuel lines running from the firewall and instrument panel to the fuselage center section. I had to modify the tunnel cover to relieve the 90-degree angle at its forward end and so create more room for wiring.

This bit of aluminum turns the tunnel’s 90-degree bend into two 45-degree bends and creates more room for wire.

Another picture? Sure!

That solved one problem in this area, but I still had another one – as I ran wiring from the tunnel to the center section I forgot to leave room behind the fuel selector for the J-shaped tube that connects it to the fuel filter/pump assembly. Oops.

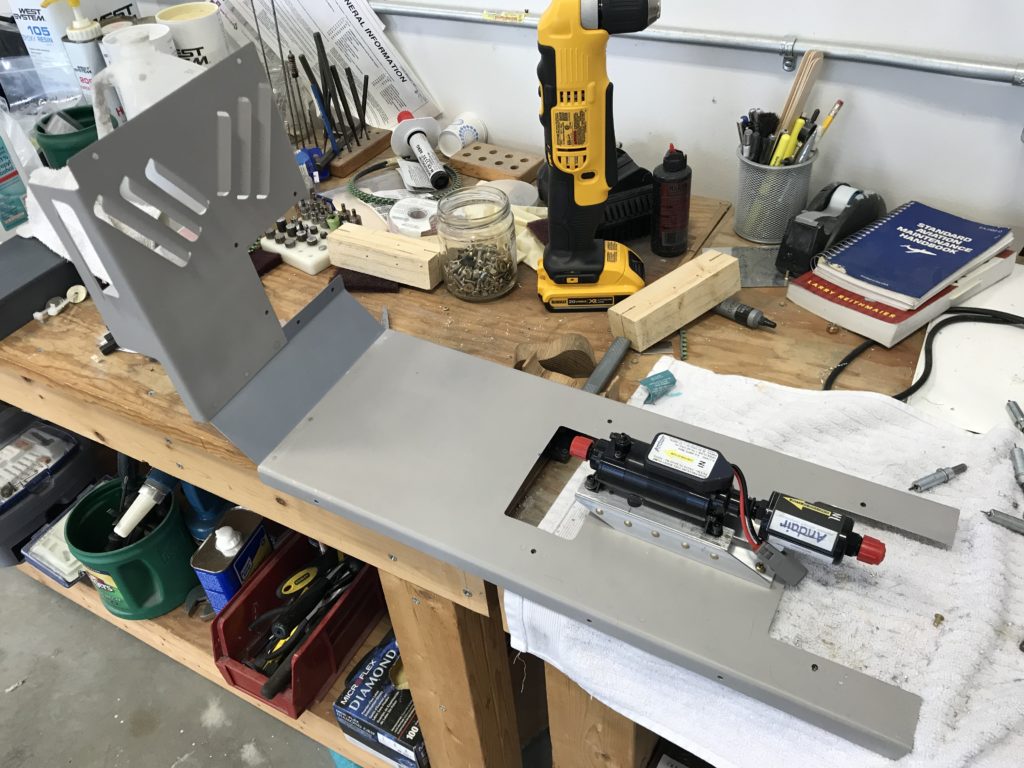

The solution was to fabricate a bracket that moves the pump/filter up and forward enough to accommodate an L-shaped fuel line that doesn’t interfere with the wire bundles behind it.

The solution was to fabricate a bracket that moves the pump/filter up and forward enough to accommodate an L-shaped fuel line that doesn’t interfere with the wire bundles behind it.

The bracket attaches to the existing pump mounting holes in the tunnel cover. This created a challenging fuel line run from the pump outlet to the firewall but Tom Swearingen at TS Flightlines solved the problem with a well-crafted flexible fuel line with a 90-degree fitting on one end.

The bracket attaches to the existing pump mounting holes in the tunnel cover. This created a challenging fuel line run from the pump outlet to the firewall but Tom Swearingen at TS Flightlines solved the problem with a well-crafted flexible fuel line with a 90-degree fitting on one end.

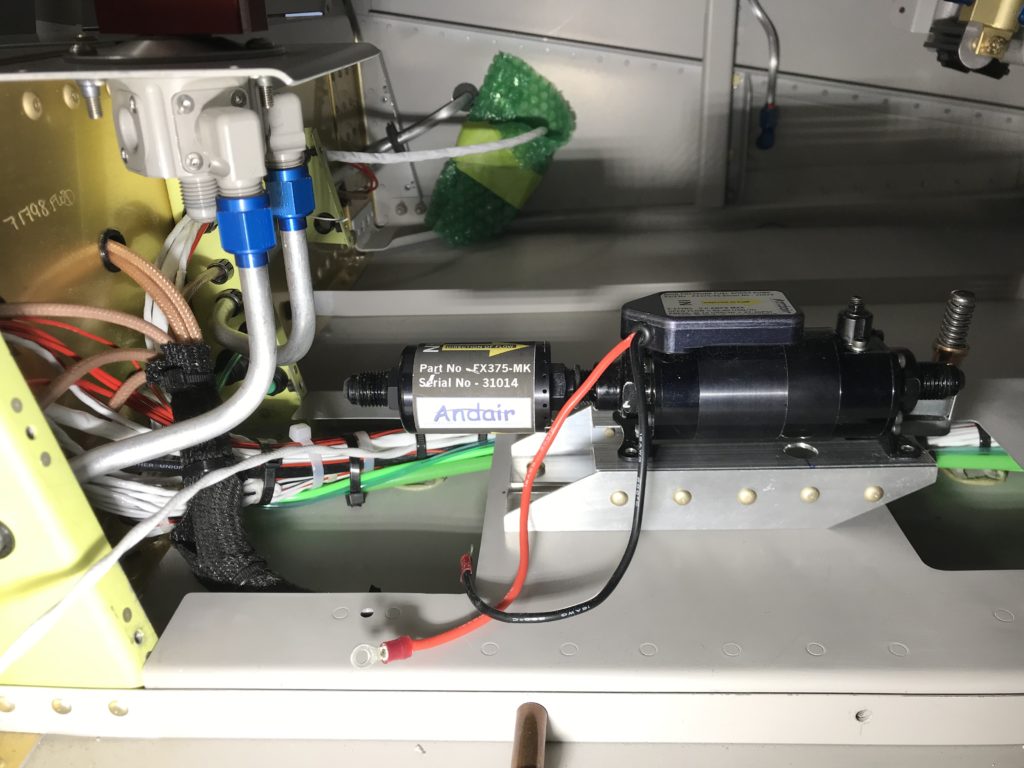

The end result – a tunnel that fits nicely in the fuselage and a pump/filter that connects nicely to the fuel selector.

The end result – a tunnel that fits nicely in the fuselage and a pump/filter that connects nicely to the fuel selector.