With the fuselage upright on the cradle, I needed a way to level it from side to side and forward to aft to prepare for drilling the aft deck. Being the obsessive engineer that I am, I wanted a way to make small adjustments and re-level if necessary. After a little braining on the problem, I came up with this poor man’s jackscrew.

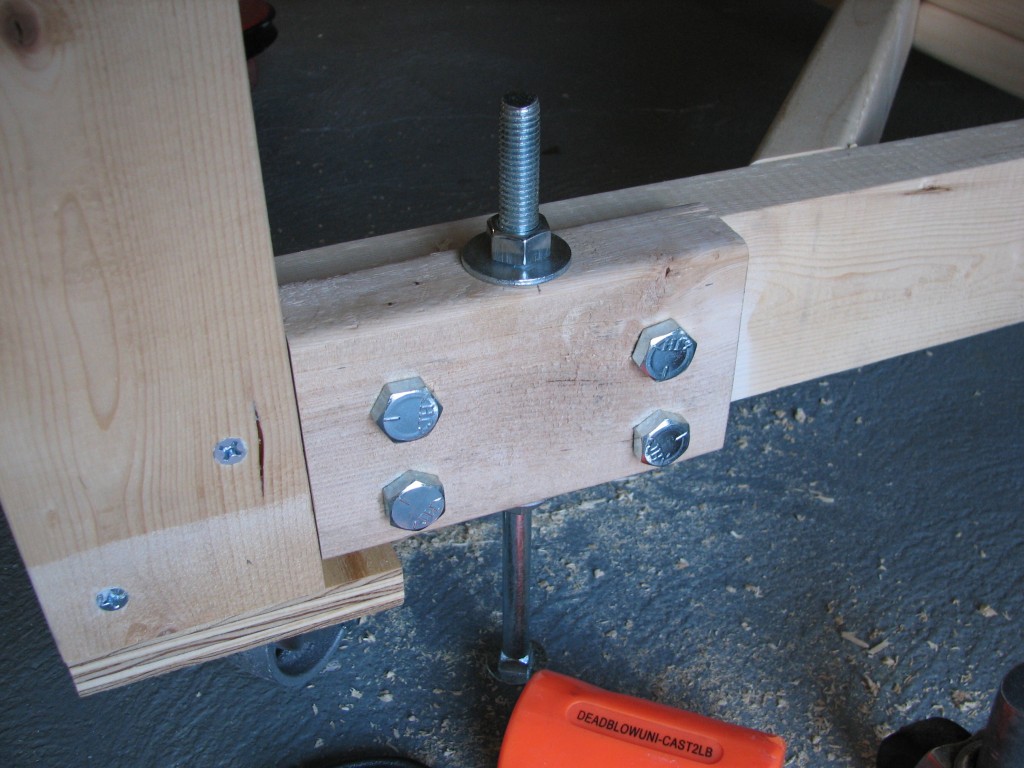

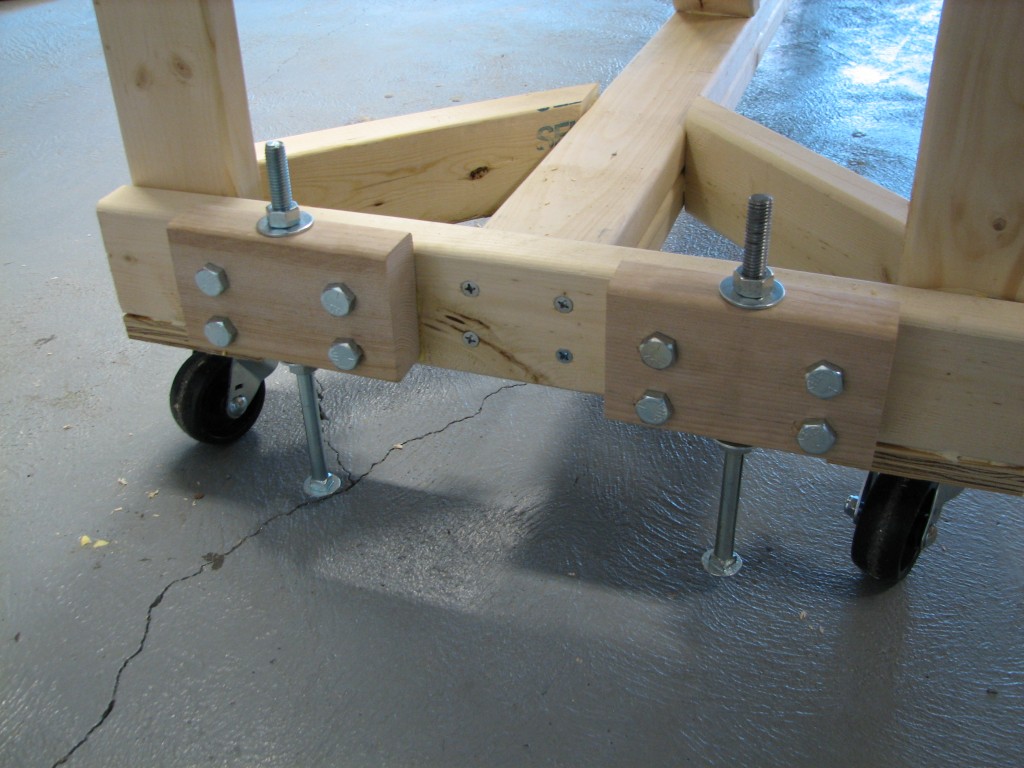

It’s a 1/2″ bolt centered in a piece of fir 2″x4″, and I made four of them – one for each corner of the cradle. The bolt head will rest on the floor, and the bottom nut will adjust the bolt up and down.

It’s a 1/2″ bolt centered in a piece of fir 2″x4″, and I made four of them – one for each corner of the cradle. The bolt head will rest on the floor, and the bottom nut will adjust the bolt up and down.

They’re bolted in place with more 1/2″ fasteners. I used heavier hardware than was probably needed, but I want to be able to use the same system to keep the fuse nice and level when mounting the wings so a little overkill is justified.

They’re bolted in place with more 1/2″ fasteners. I used heavier hardware than was probably needed, but I want to be able to use the same system to keep the fuse nice and level when mounting the wings so a little overkill is justified.

With the jackscrews in place on all four corners, I leveled the fuse across the center section…the jackscrews made this really easy.

With the jackscrews in place on all four corners, I leveled the fuse across the center section…the jackscrews made this really easy.

Looks good…nice and level. Amazingly, when I placed the level on the tailcone I found..

Looks good…nice and level. Amazingly, when I placed the level on the tailcone I found..

..it’s level too. This is A Good Thing, it means the fuselage has practically no twist, and that all the work I did to keep the fuse level while riveting, really paid off. The digital level occasionally showed 0.1 degree off – still completely acceptable – but with a little tweaking I got it back to dead center. Very cool.

..it’s level too. This is A Good Thing, it means the fuselage has practically no twist, and that all the work I did to keep the fuse level while riveting, really paid off. The digital level occasionally showed 0.1 degree off – still completely acceptable – but with a little tweaking I got it back to dead center. Very cool.