My EAA volunteer Tech Counselor came over this weekend. With the fuse upright, I wanted another set of expert eyes to look at our work. We ended up fixing a handful of rivets that needed a few more hits with the gun, and also drilled out and replaced a couple that I wasn’t happy with. All in all, it was a successful inspection and Bob thinks we’re building a fine ship. Thanks again, Bob!

While Bob was around we rechecked the fuselage level and made a couple of tweaks, then drilled the aft deck. This is an important step, since once the deck is in place, the fuselage is torsionally rigid – any twist is locked in for good.

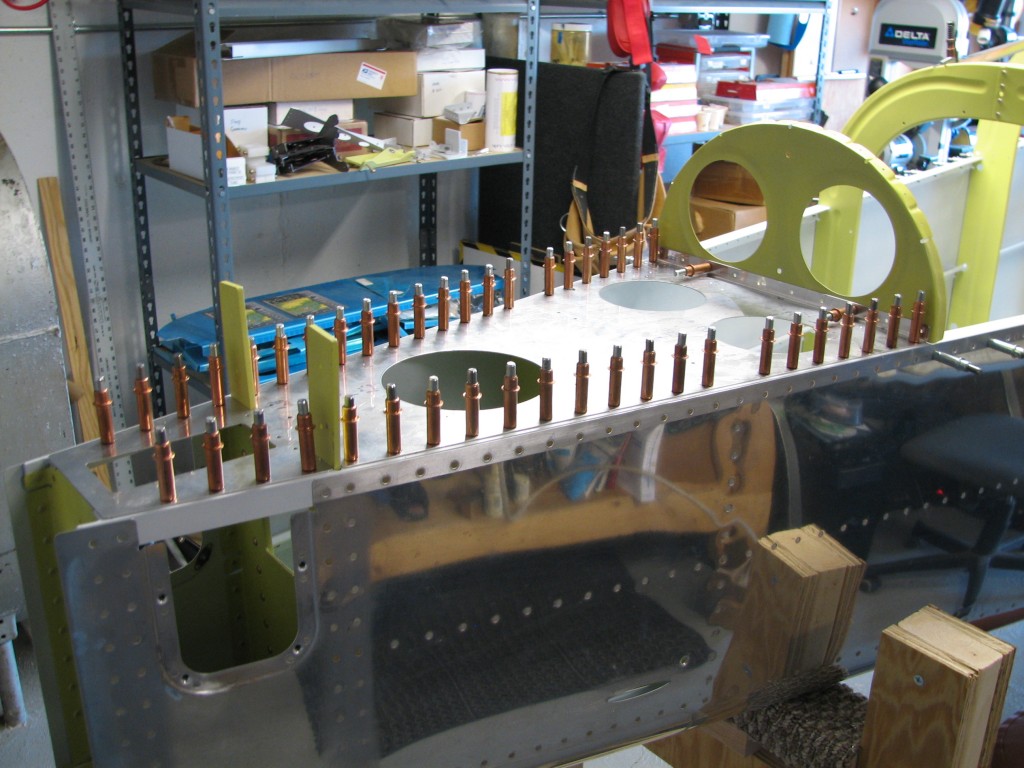

With level double-checked, I clamped the deck in place and drilled it to the longerons…

…and boy is this structure stiff when the deck is in place. After drilling – and making a big mess with aluminum shavings – I pulled the deck off and fabricated a couple of spacers for the aft bulkheads.

…and boy is this structure stiff when the deck is in place. After drilling – and making a big mess with aluminum shavings – I pulled the deck off and fabricated a couple of spacers for the aft bulkheads.

Turns out that there’s a little gap that will need to be shimmed on the forward bulkhead –

Turns out that there’s a little gap that will need to be shimmed on the forward bulkhead –