I have a whole laundry list of things that need to be done now that the wings are fitted.

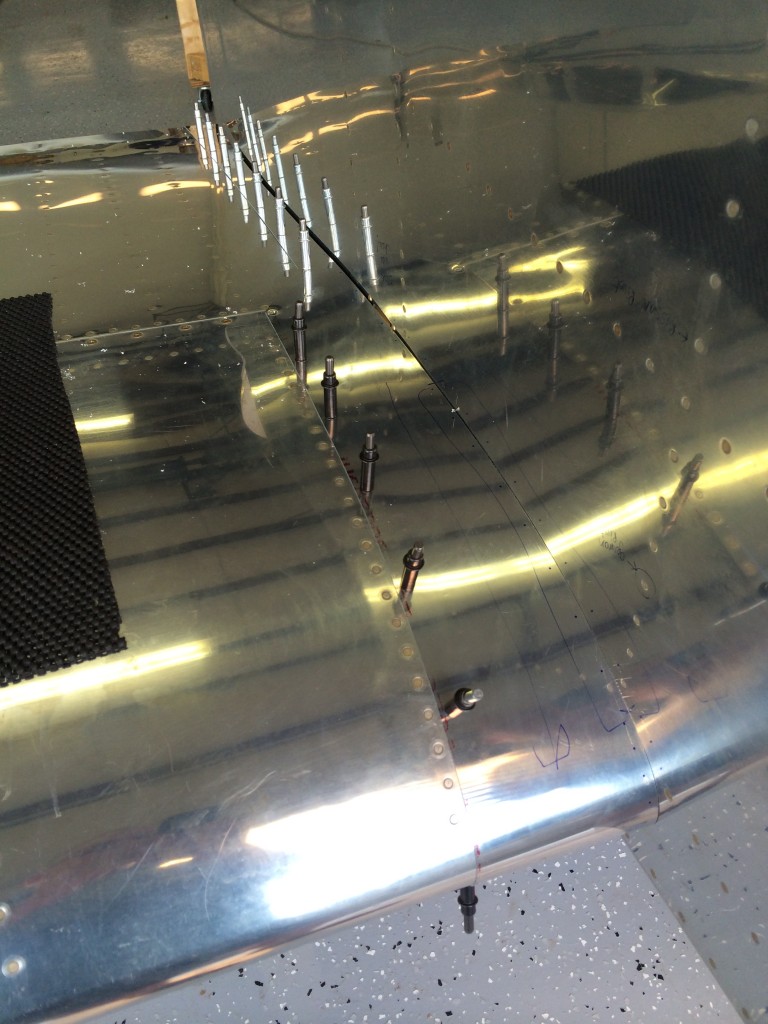

First up was fitting the wing root fairings. Nothing too difficult here…the only trick is getting the fairing to conform to the wing leading edge curve enough to get all the holes aligned with those in the wing. A little hand shaping of that area solved the hole alignment problem.

I realized that I made a small mistake several years ago when I built the wings – I match-drilled and dimpled several of the wing skin/rib holes that should have been left undrilled for the fairing attach screws. Looks like I’ll have to drill them out to the right size (#19) and then re-dimple to accept a #8 screw. No big deal.

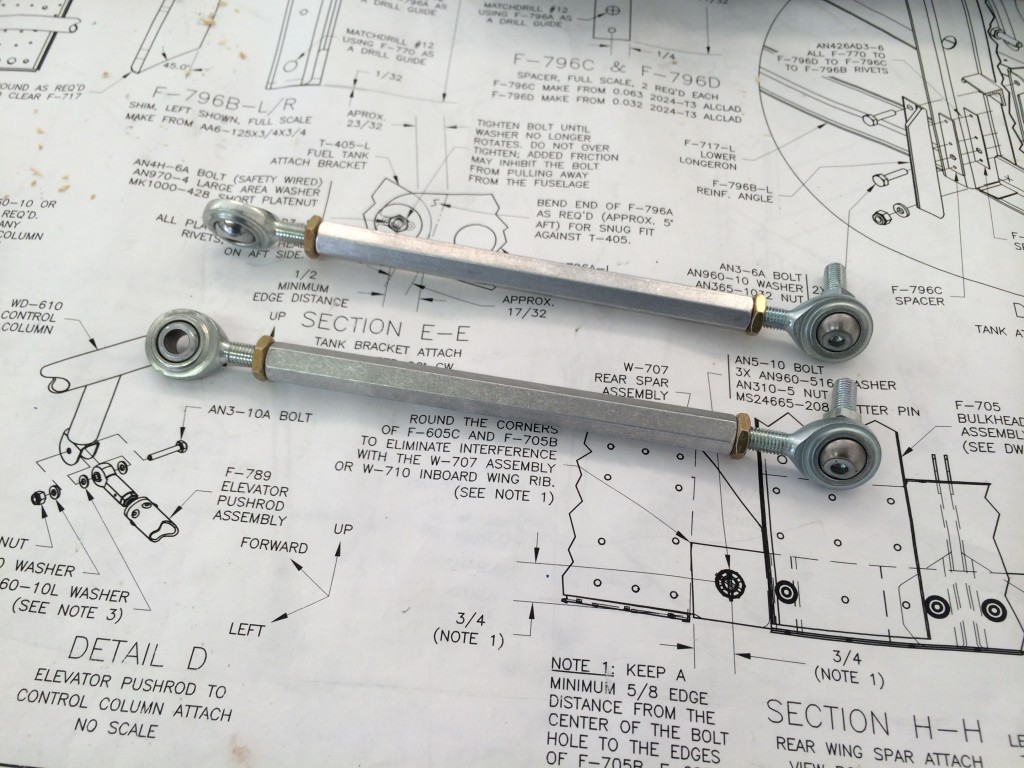

While I was at Oshkosh I bought these spiffy pre-drilled hex flap pushrods rods from Avery Tools. Drilling and tapping a piece of round tube stock for these pushrods per plans is a pain, so these Avery rods save a lot of time and effort…just screw in the rod ends, and you’re done. Cool.

While I was at Oshkosh I bought these spiffy pre-drilled hex flap pushrods rods from Avery Tools. Drilling and tapping a piece of round tube stock for these pushrods per plans is a pain, so these Avery rods save a lot of time and effort…just screw in the rod ends, and you’re done. Cool.