…Nav antenna, that is. I had always planned on using a Bob Archer-designed wingtip Nav antenna because they work well for horizontally-polarized ILS/LOC/GS signals and also fit nicely within the wingtip fairings, thus eliminating a tiny bit of parasitic drag. You can find Bob Archer’s description of his antennas here and instruction/plans for building them here on Van’s Air Force.

I was all set to buy one of Bob’s antennas from Aircraft Spruce. But since I’m an Electrical Engineer by education (can’t spell “geek” without EE) as well as an airplane homebuilder and ham radio operator (N1DLS), I decided to make my own antenna out of some materials I had laying around the shop and a piece of fiber/resin circuit board material I bought from McMaster Carr.

There’s nothing difficult about fabricating the antenna, it’s only an afternoon’s work to put one together using plans you’ll find on the interwebs.

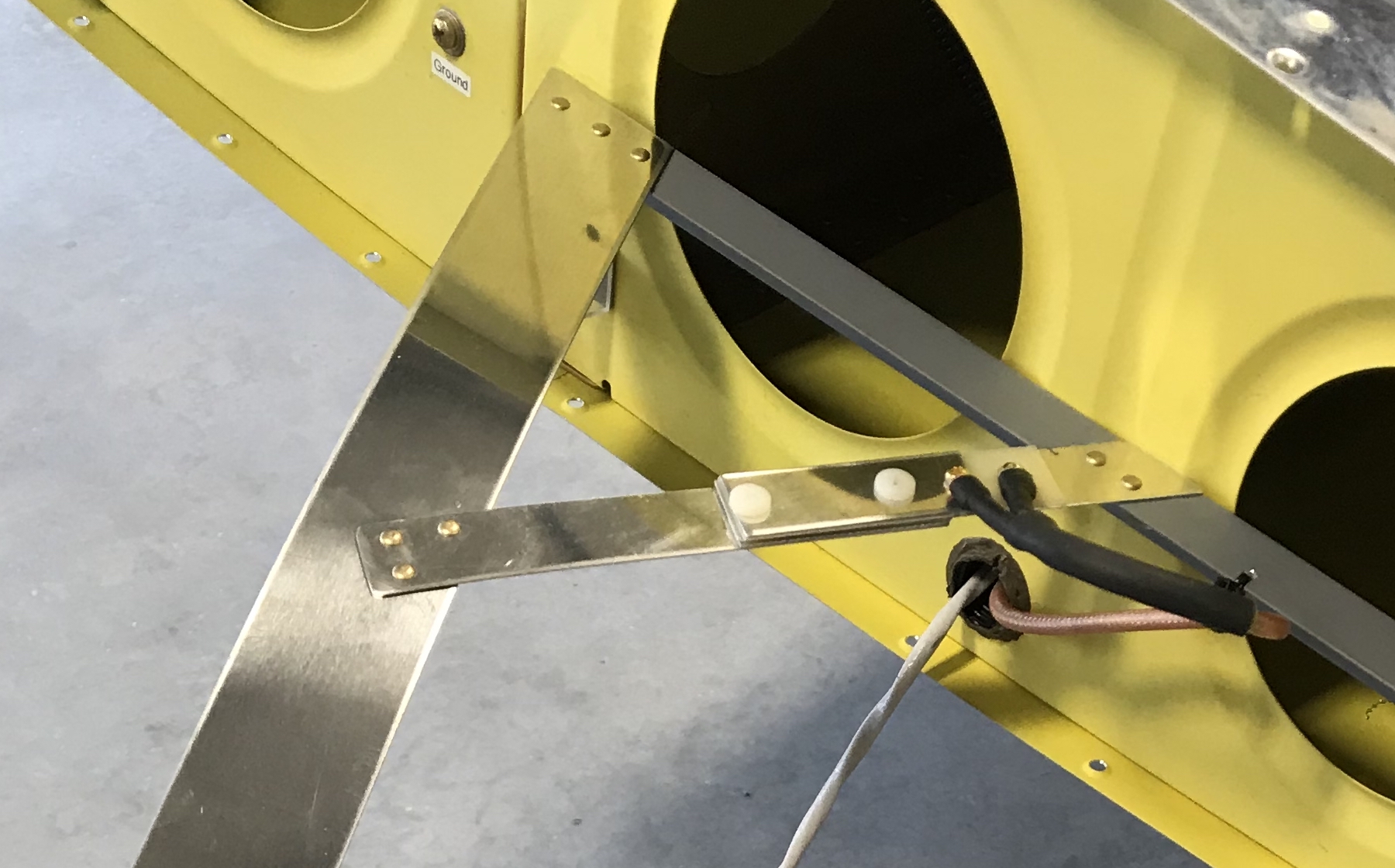

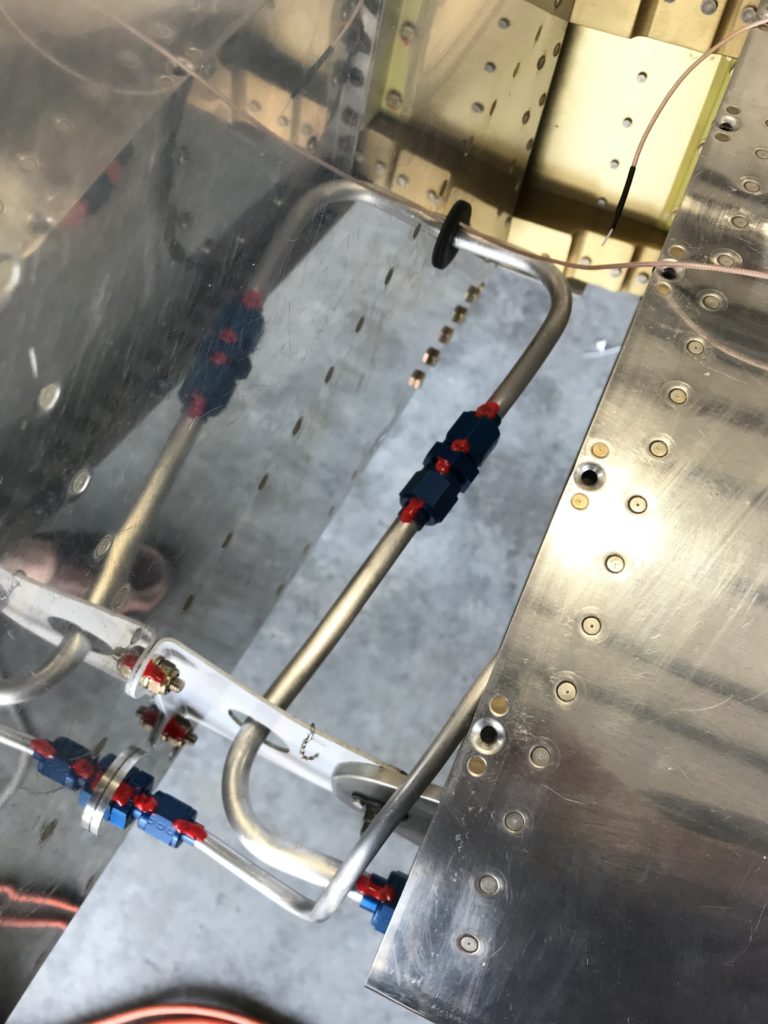

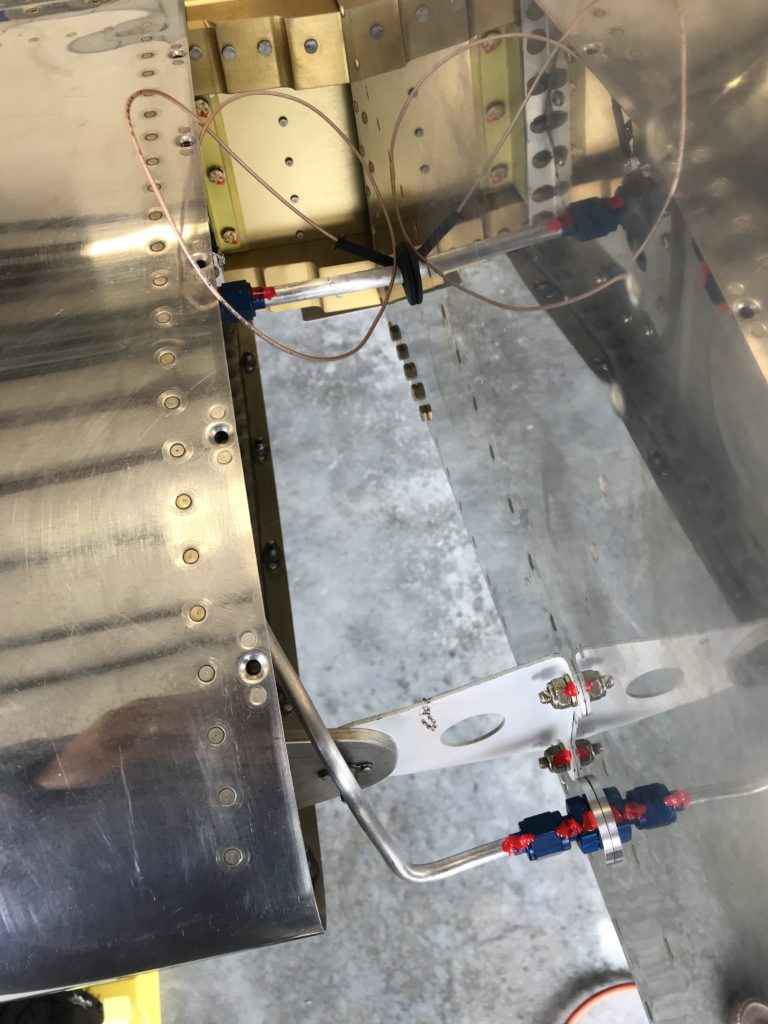

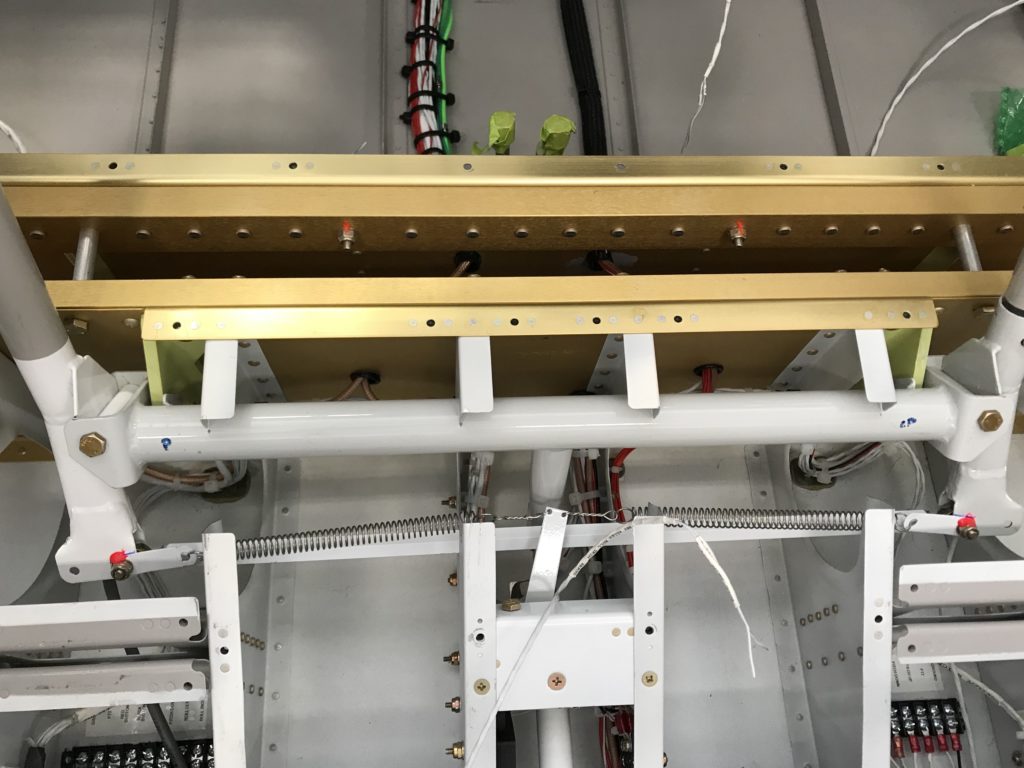

The magic in this antenna lies in a couple of areas – the gamma-match coax impedance-matching device, which is the narrow aluminum and fiberglass structure to which the coax connects, and the length of the long outboard aluminum strip that’s parallel to the wing. The antenna must also be well-grounded to the aircraft, hence the big piece of aluminum angle that holds it onto the wing.

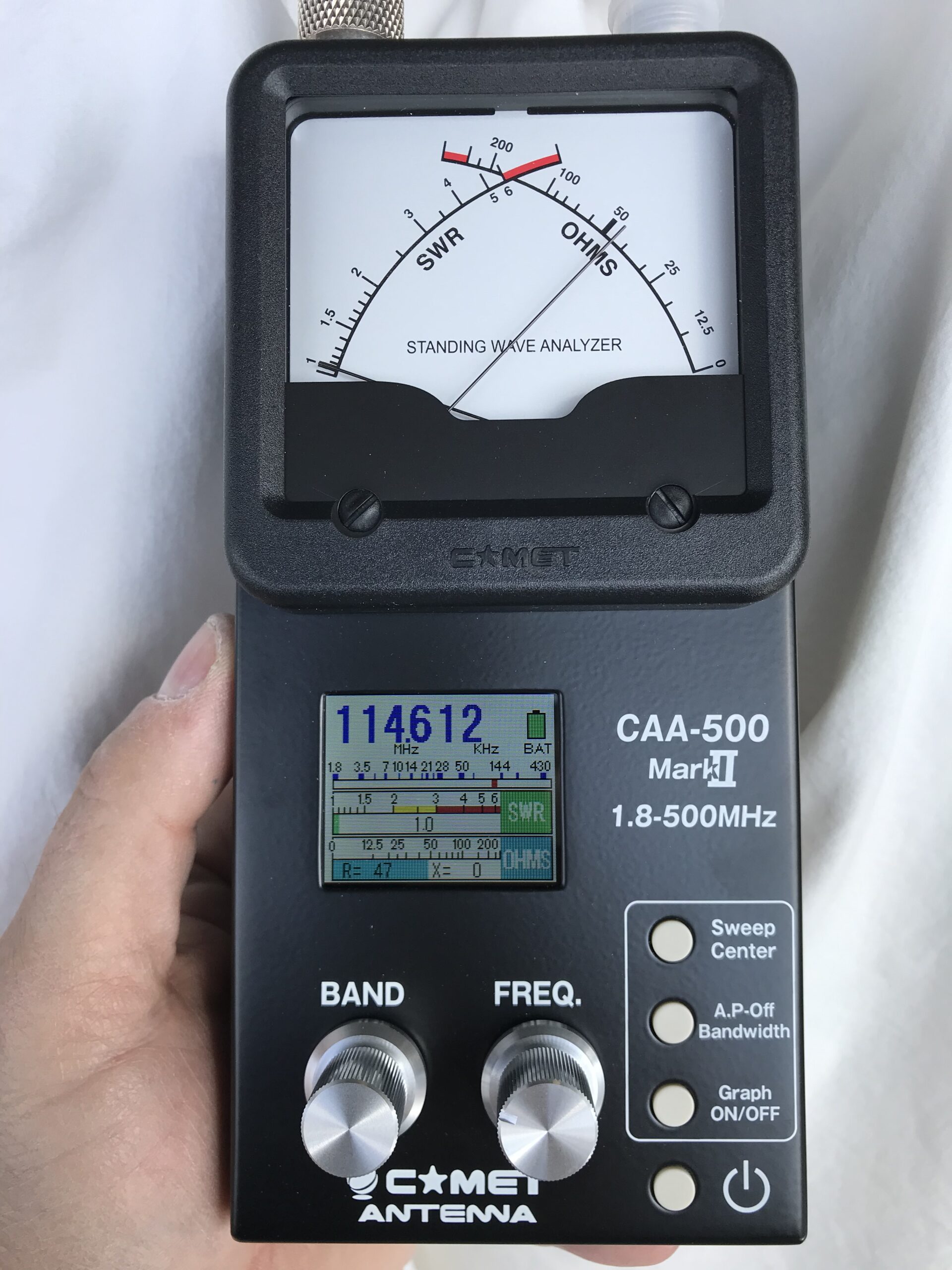

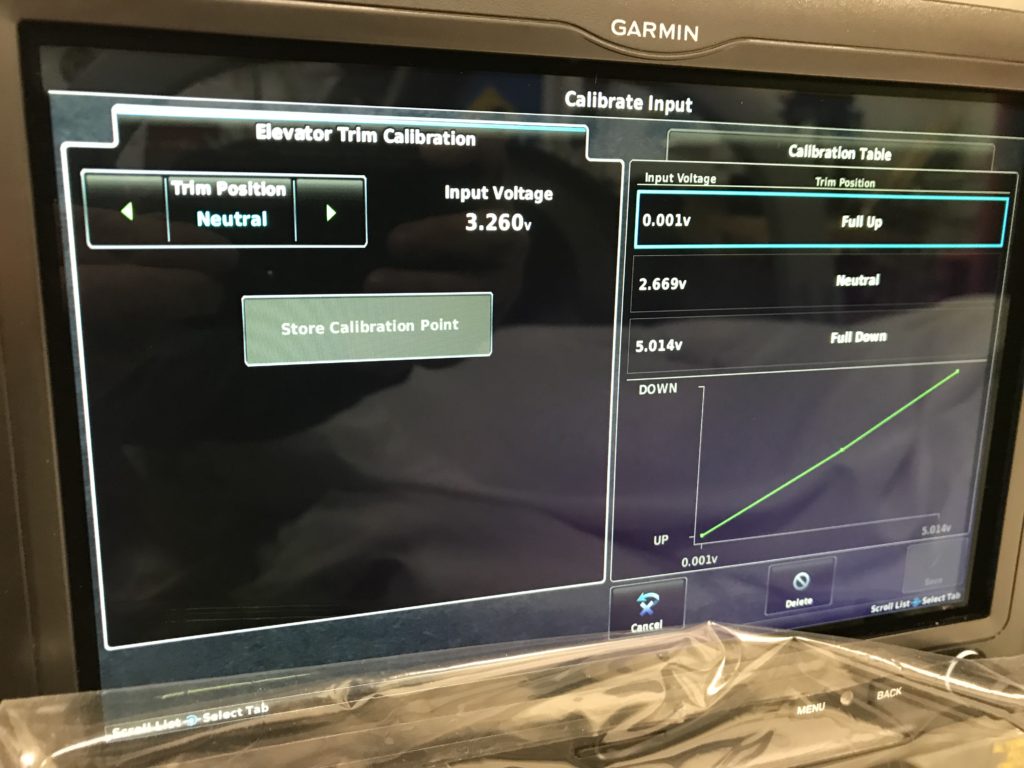

So how does the novice Archer antenna builder know how to adjust these magic bits? The answer is an antenna analyzer, something which no self-respecting ham radio nerd would be without. Here’s mine –

The instructions should tell you how to tune the antenna but if you need help and an antenna analyzer as well, hit up your nearest airplane-building ham radio buddy (there are a lot of us) and he/she/I will be glad to help.

After several iterations of adjusting the gamma match and antenna length, I had a well-tuned and matched antenna…I hope. The analyzer picture below shows that the antenna is almost perfectly matched at 114 MHz. I can live with that.

And here’s the final product –