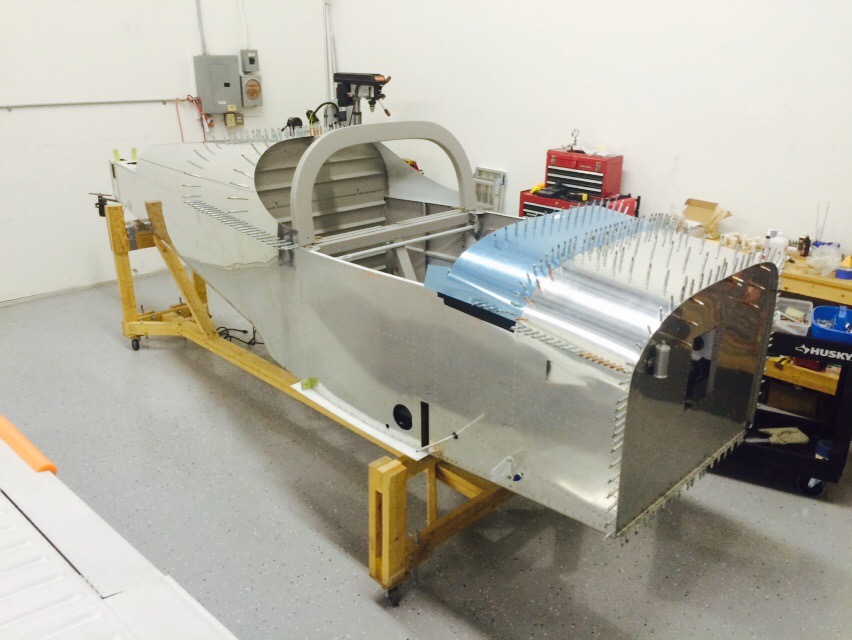

I’m following the EAA Flight Test Manual and Test Cards and the last test required before first flight is taxi and brake burn-in. Landing gear and tailwheel setup on the RV-7 are straightforward so I didn’t anticipate any steering problems on the ground, but like any aircraft test it’s the things you don’t expect that can really bite you. And since brake burn-in requires 25-30 knots groundspeed, I planned to verify steering in a large, open ramp area before heading out to the runway for higher-speed stuff.

Fortunately, the RV-7 is very well-mannered on the ground and I had no problems with brakes or steering as I taxied to the ramp. A quick check on Comm 1 and 2 was also successful, and engine EGTs/CHTs were stable and within expected ranges.

Fortunately, the RV-7 is very well-mannered on the ground and I had no problems with brakes or steering as I taxied to the ramp. A quick check on Comm 1 and 2 was also successful, and engine EGTs/CHTs were stable and within expected ranges.

Here’s a nice video courtesy of Ellen…

The only problem I encountered was minor landing gear shimmy – if you look closely in the video below, you’ll see the main gear tires oscillating just a bit. This is common to RVs and most builders correct it by adjusting tire pressure, adding wood stiffeners to the gear legs, or both.

Big props to Ellen…she was my ground crew and called on the radio to ask if I felt vibration, which I did, but wasn’t sure what it was.

After finishing taxi tests and brake burn-in, I finished the G3x full-power vibration survey and magnetometer calibration. It’s good to have the avionics completely done!

Thanks to Burt Wadas for being my official ground-test photographer!

Thanks to Burt Wadas for being my official ground-test photographer!