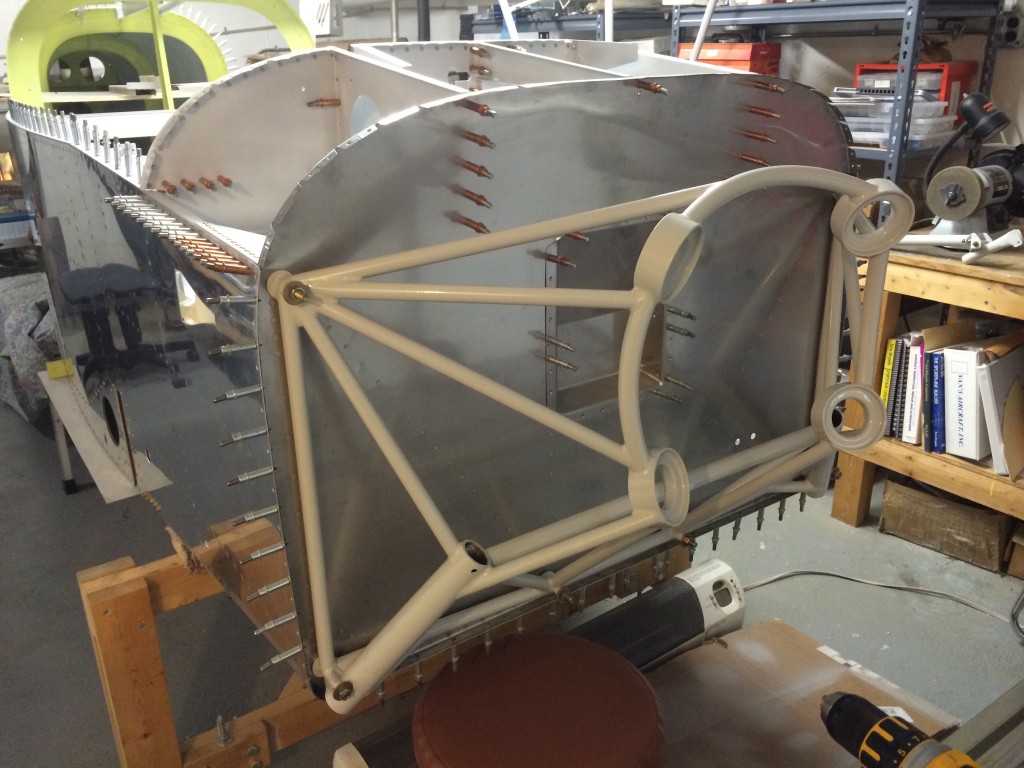

It’s looking likely that I’ll be ready for an engine sometime this summer and over the last year I’ve been working through the various engine options for our RV. Many years ago I decided that the engine would be some variant of the 180 horsepower Lycoming IO-360-M1B with a horizontal sump and set up for a constant-speed propeller. I’ve already purchased a finishing kit from Van’s that includes a cowl for this configuration.

When I first started building the RV, I planned to buy a certified Lycoming engine from Van’s because of the excellent prices they offer to RV builders. But since Van’s now only carries experimental versions of Lycoming engines, and there’s competition in the experimental market to keep prices down, we decided to expand our search and look at ECI Titan and Superior XP-360 experimental engines from other vendors.

An advantage to buying an experimental engine from one of these vendors is that they do some value-added work like flow-matching cylinders and balancing rotating components. I really want a smooth-running engine, and these tweaks apparently help. Had we been buying an engine a few years ago, we might well have worked with Mattituck Services on Long Island. They had an excellent reputation for customer service and sold experimental engines to many local RV builders. But they no longer exist as a custom engine builder, so that option was out. I had also been investigating engines from Aero Sport Power in Kamloops, British Columbia. Many west-coast RV builders, including my good friend Jim Piavis, bought engines from Aero Sport and have been very happy with them because of their great after-the-sale support. I defintely want that kind of support from my engine provider.

One of the factors in my selection process was the choice of fuel injection systems. I’d pretty much settled on a Precision Silverhawk EX system because it’s the experimental version of, and identical to, the proven Bendix RSA system that I’ve flown on Piper Arrows. Until recently, experimental Lycoming engines sold through Van’s came with the Precision system but as of 2014 Lycoming switched to Avstar fuel injection systems – essentially a knockoff of the Precision system. I’ve had several interactions with Alan Jesmer and the folks at Precision, and decided that I wanted my engine to have their FI system. Since Van’s wasn’t willing to customize the Lycoming engines they sell, this wound up being a vote against buying an engine from them.

I had almost decided to buy my engine from Aero Sport this spring, but decided to ask my A&P/IA friends around Boston about local engine providers. They all pointed me to Tim Hess at Unlimited Aero Engines at the Fitchburg, MA airport (KFIT). Tim was formerly the Crew Chief on Mike Goulian‘s Red Bull air race team, he’s built highly customized, high performance engines for Mike and Kirby Chambliss. In addition to continued support to the Red Bull Air Race organization, Tim runs his engine shop at FIT and has done overhauls and repairs for many of my A&P friends. In short, he’s a world-class aircraft engine expert.

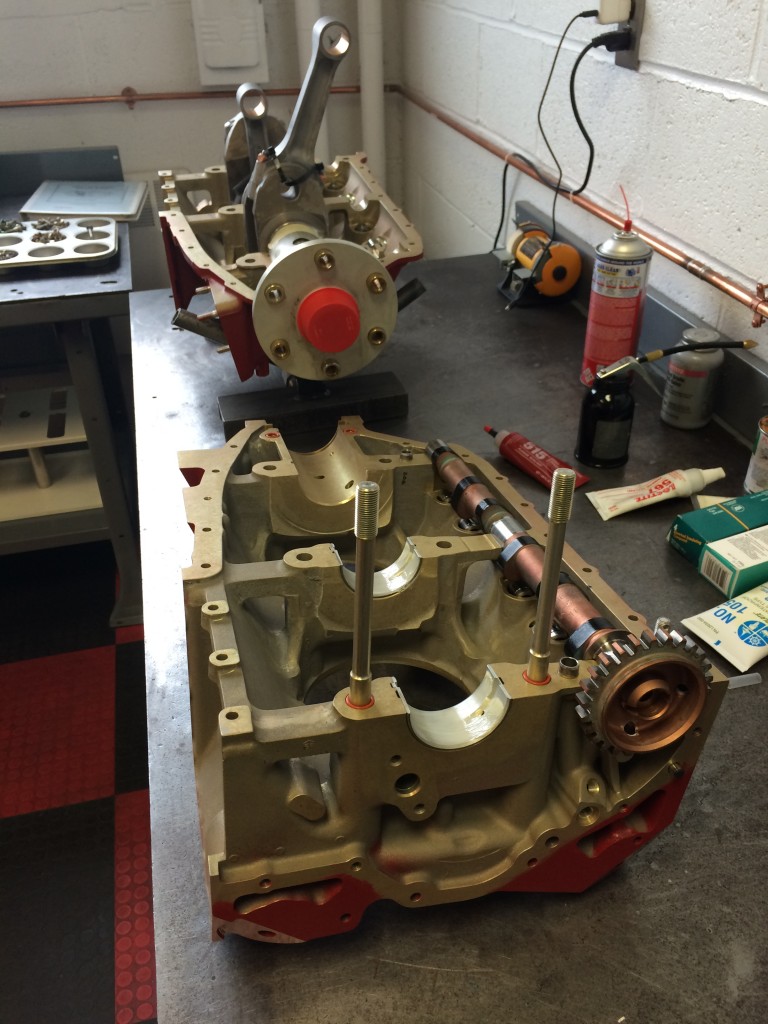

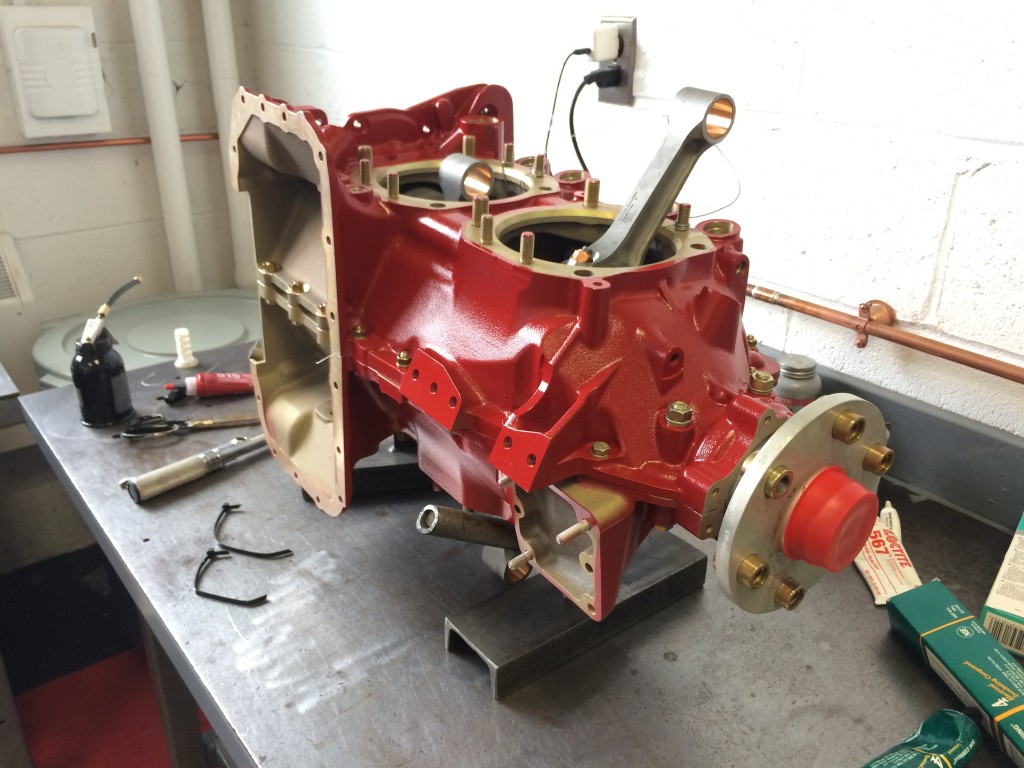

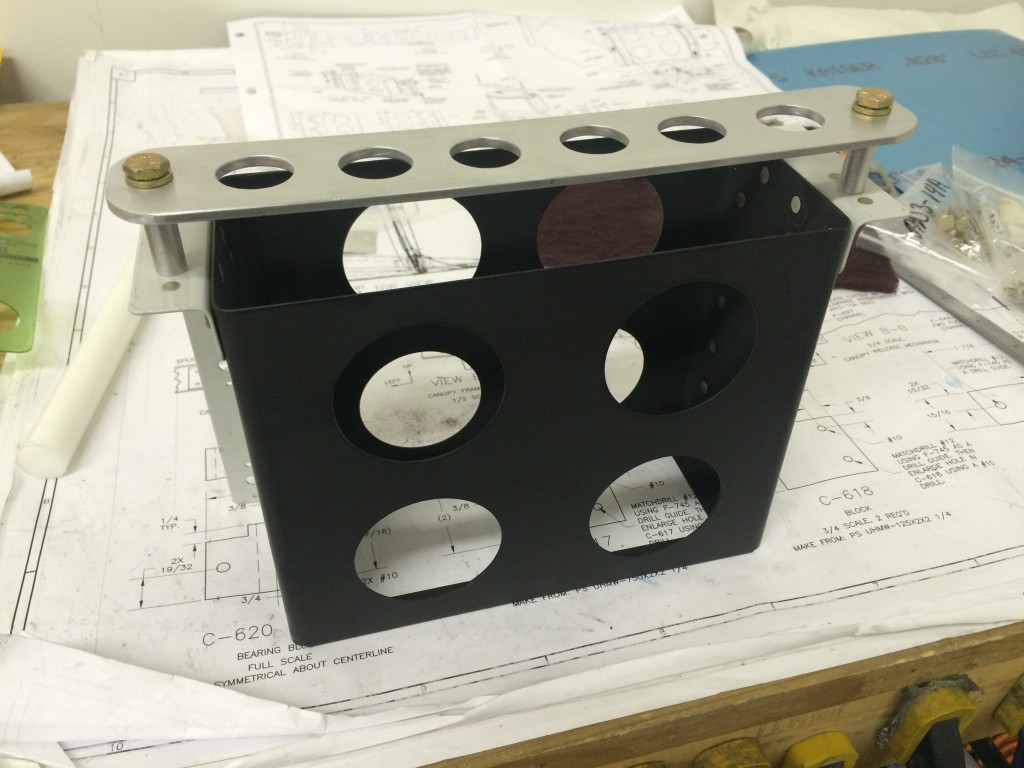

At the suggestion of my good friend Captain John, I visited Tim’s shop a couple of weeks ago and asked him for a quote on an experimental IO-360-M1B engine. He came back with a very competitive price on an custom-built Superior XP-360 with a cold-air sump and horizontal induction, roller lifters, Precision fuel injection, one PMag and one Slick mag, with flow matching, balancing, test stand run and documentation. Tim seemed really interested in building an engine for my project.

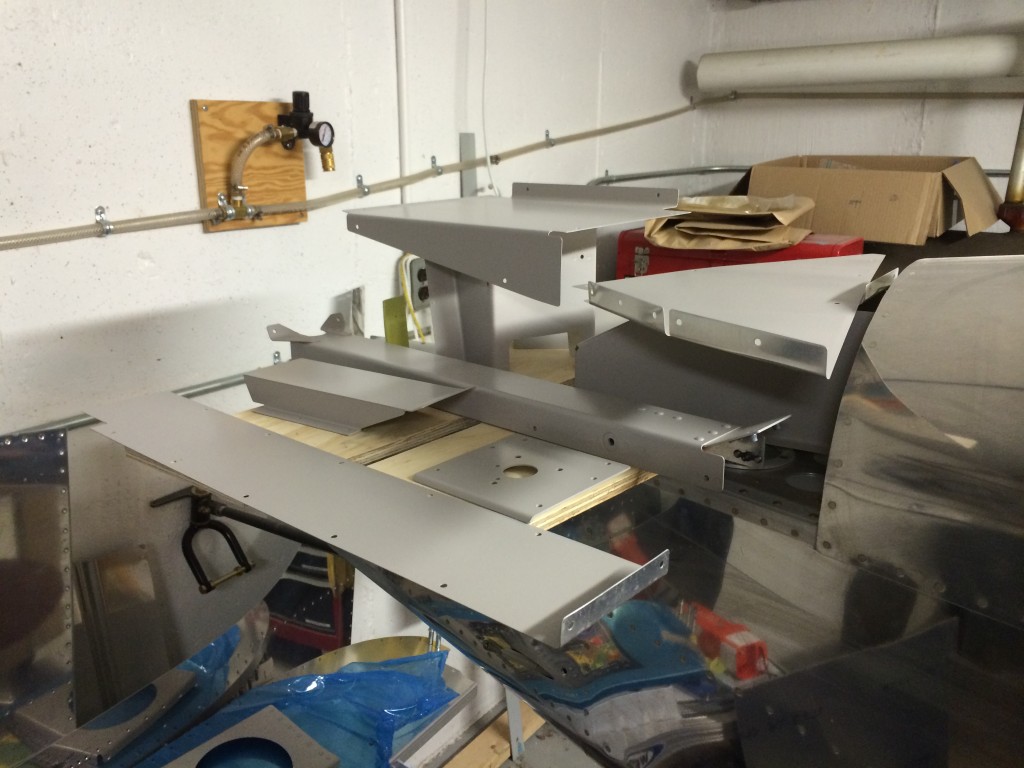

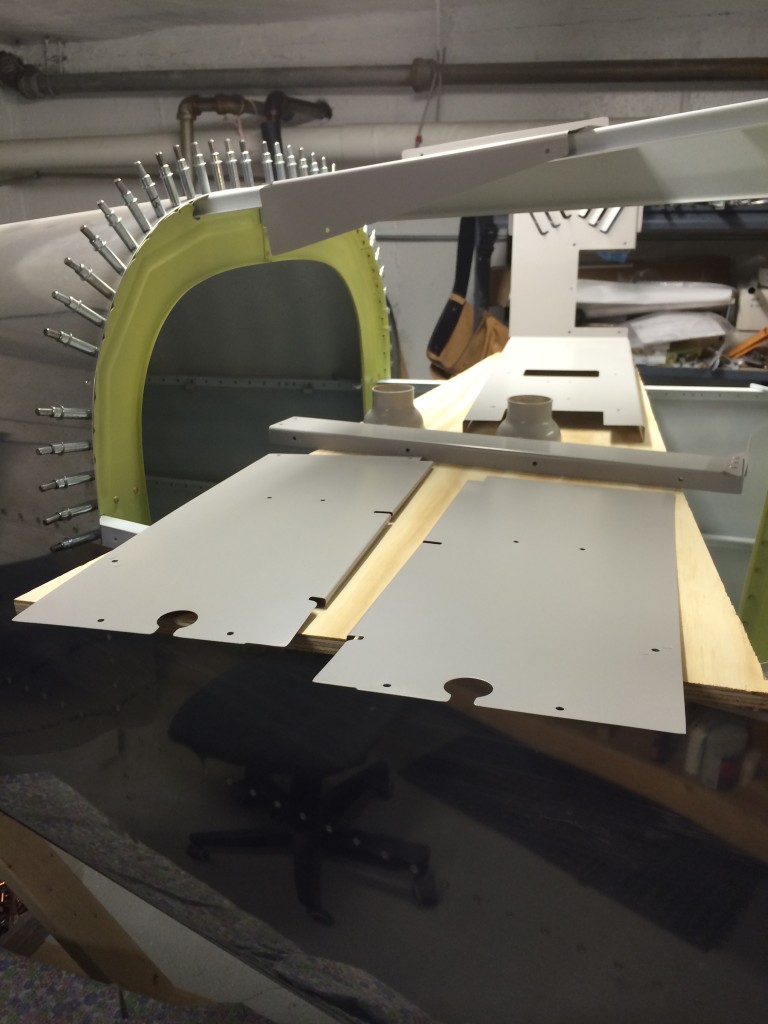

I really like the idea of working with a local shop on my engine, and it’s not every day you get a chance to work with someone like Tim who just happens to be in my aviation back yard. Plus, there’s the added benefit of having no sales tax in Massachusetts on aircraft parts. So, two days ago I wrote Tim a check for one of these…

…and sometime later this year our RV will finally have an engine. I’m looking forward to working with Tim, and I’ll be updating the website as we continue toward delivery of the engine.