Over the last month and a half I’ve been slowly working on getting the horizontal and vertical stabilators attached. There’s nothing terribly complex here, but there are some places where access for drilling holes and installing fasteners is tough.

Starting with the horizontal stabilizer, I aligned it with the fuselage per plans and drilled the inboard holes that attach the forward spar. Access isn’t so good here for a regular drill so I used the angle drill and my technique wasn’t great…despite using an undersize drill bit, the holes wound up oversize.

The outboard holes were easier to drill, but required some extra care to ensure that edge distance was maximized on the stabilizer, fuselage longerons and bulkhead. I drilled these holes initially to #30 to check alignment, then final-drilled them to #12.

I talked with Vans about how to handle the oversized inboard holes. Their recommendation was to upsize the holes to 0.25″ and use AN4 fasteners. Before I did that, though, I wanted to try a first-oversize close tolerance NAS6604 fastener that’s approximately 1/64″ larger than a norman AN3 fastener. That would preserve 2D edge distance on the hole. I reamed the oversize holes to accommodate the NAS6604 bolt, and the bolts were a perfect fit – problem solved.

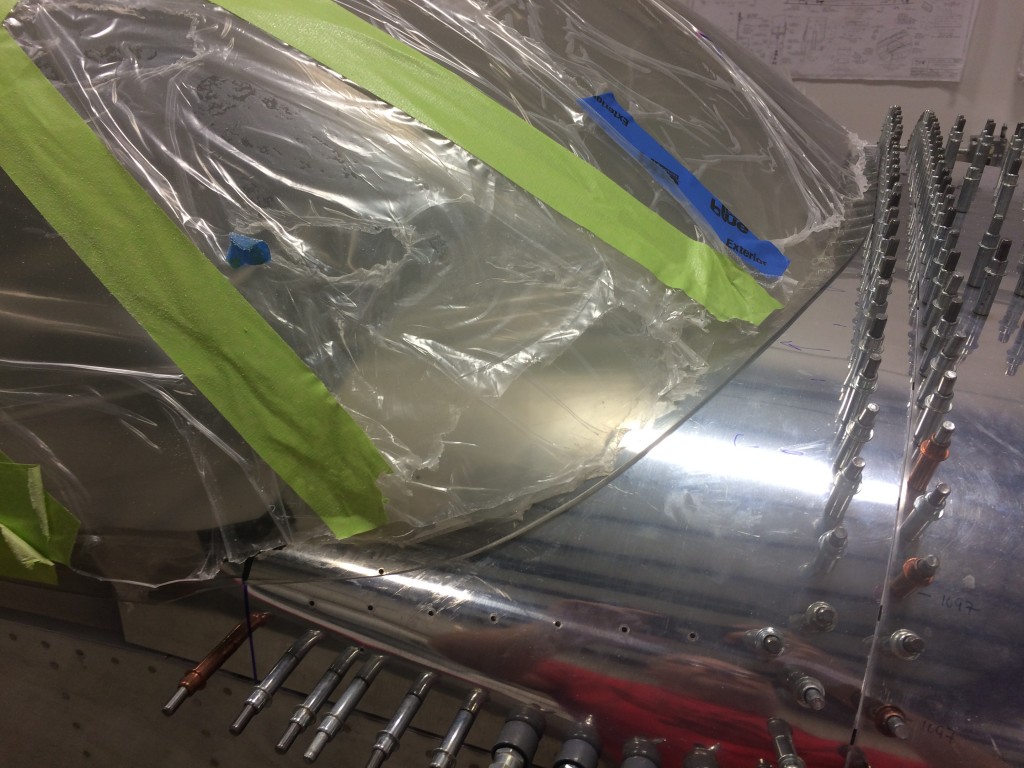

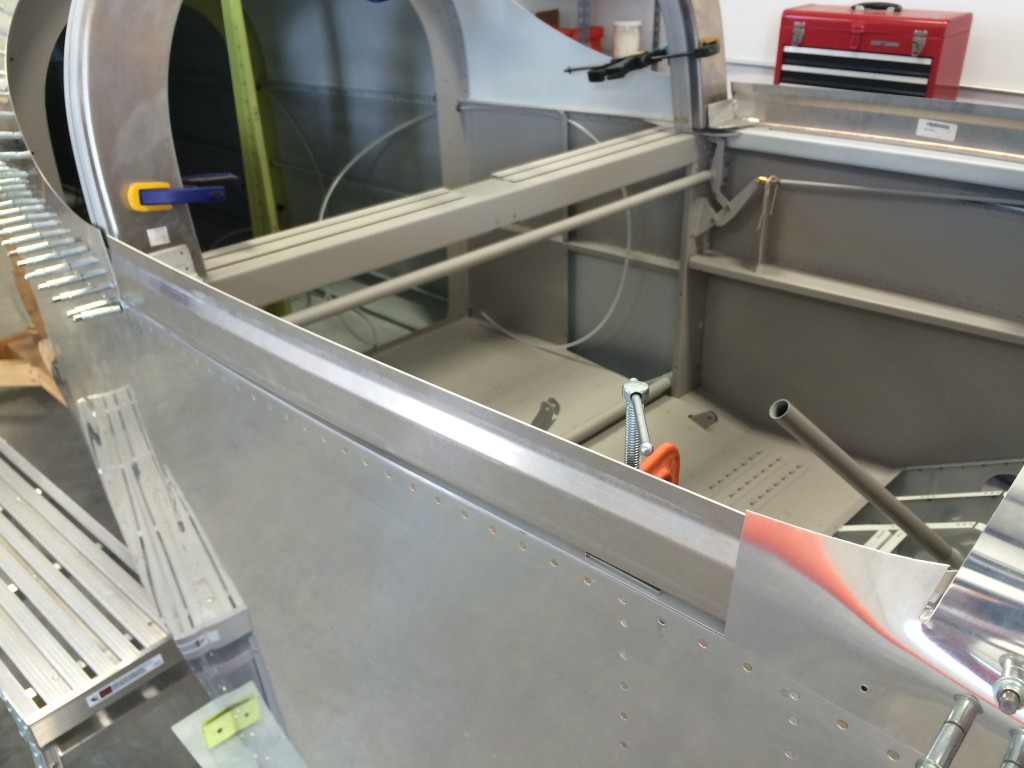

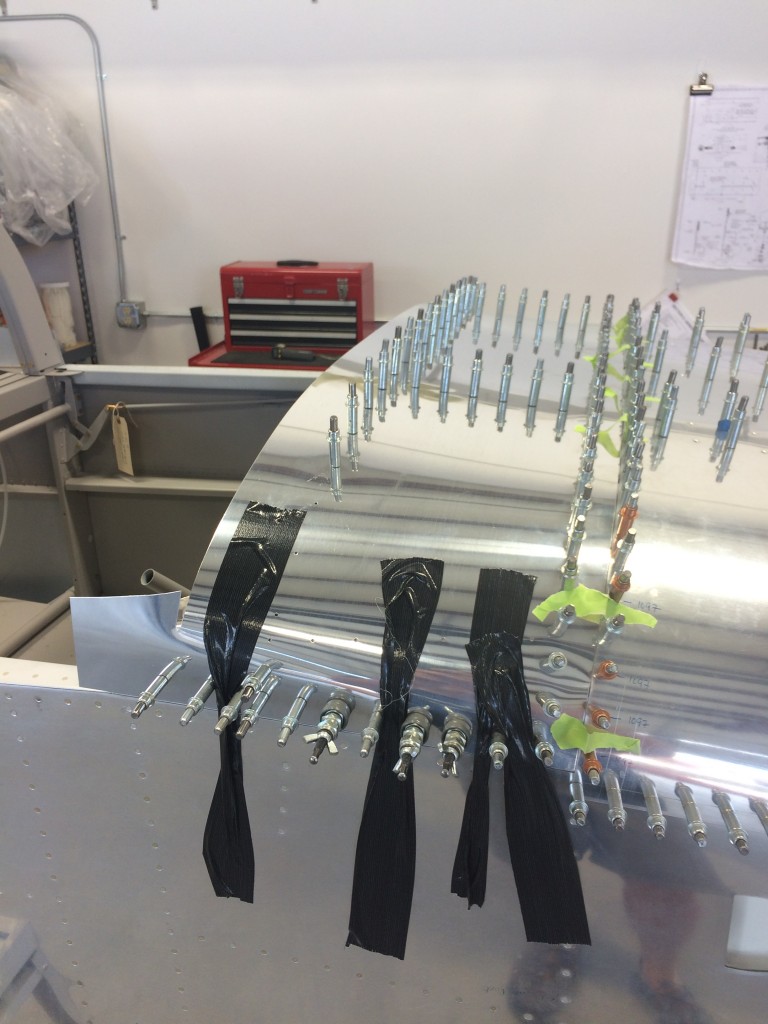

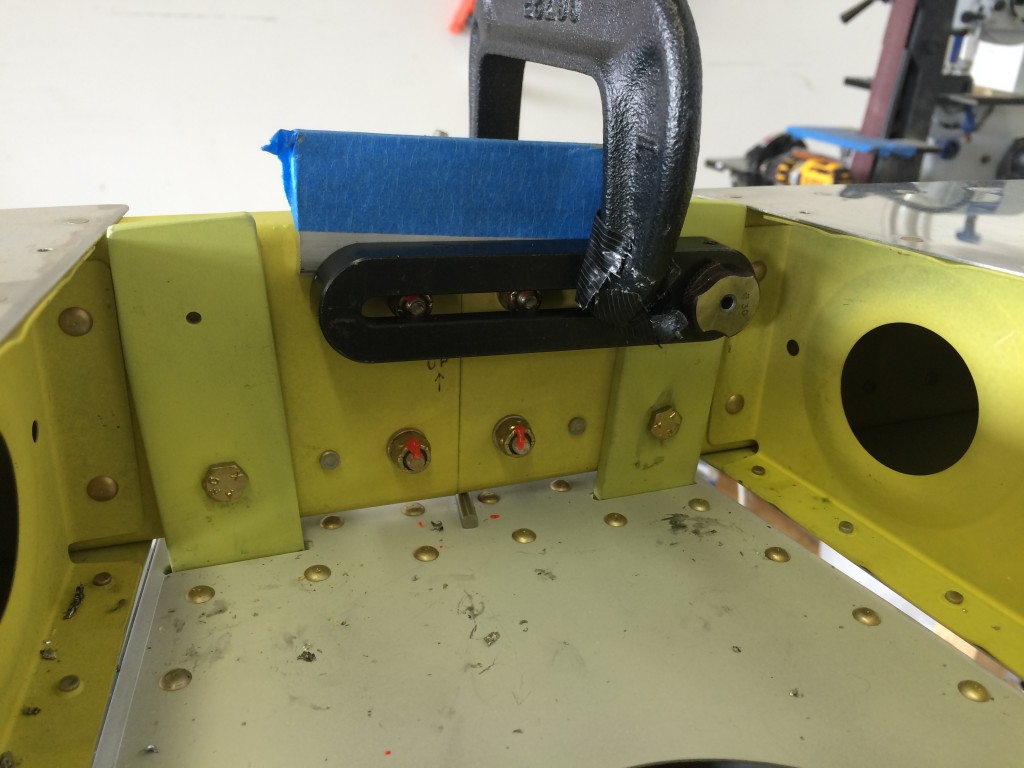

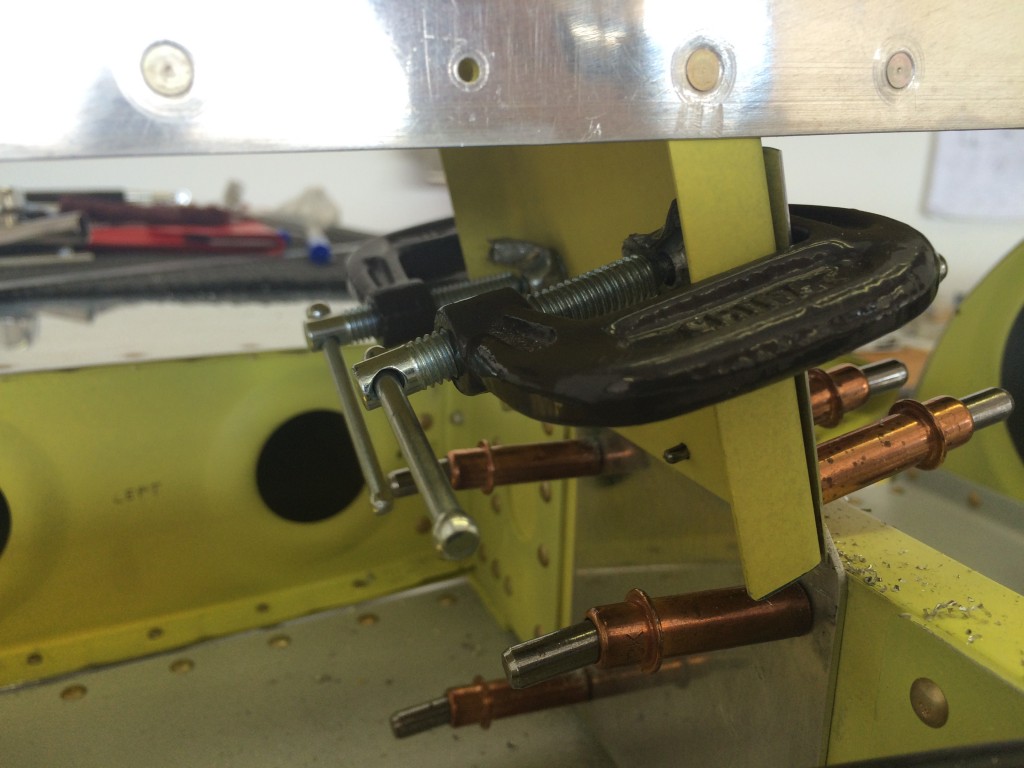

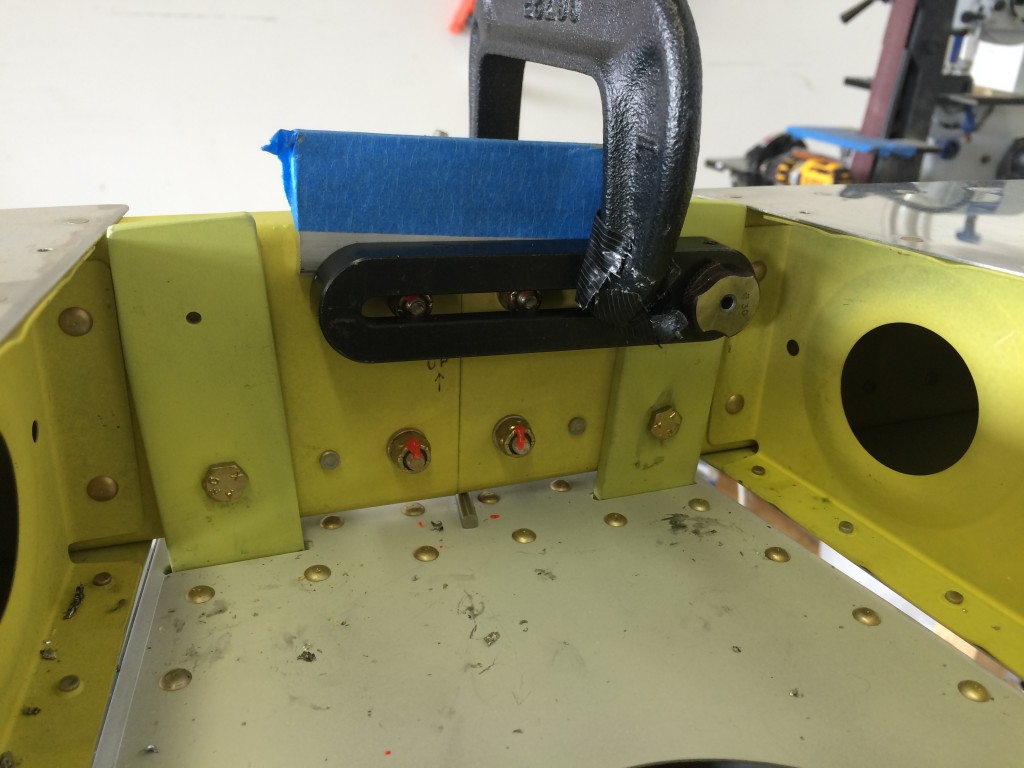

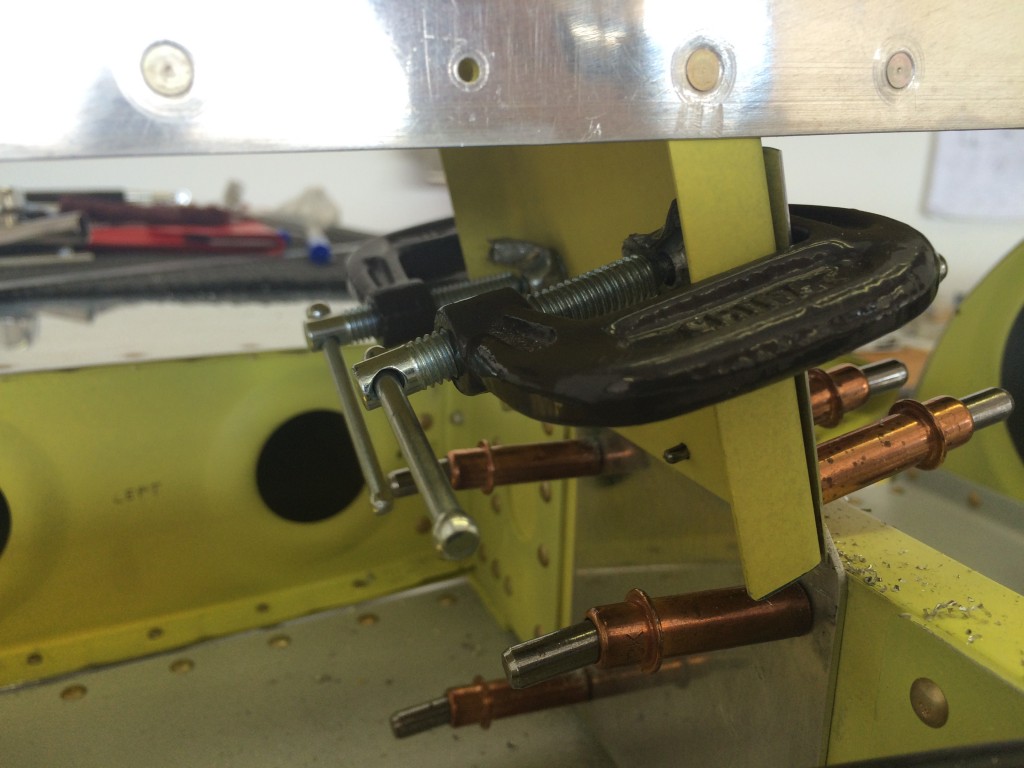

With the forward horizontal stab spar drilled to the fuse, I clamped the rear spar to the fuselage attach bars. If you look carefully, you’ll see the business end of a 3/16″ punch between the rear spar and fuselage aft deck. That 3/16″ gap establishes proper incidence for the horizontal stab relative to the fuselage.

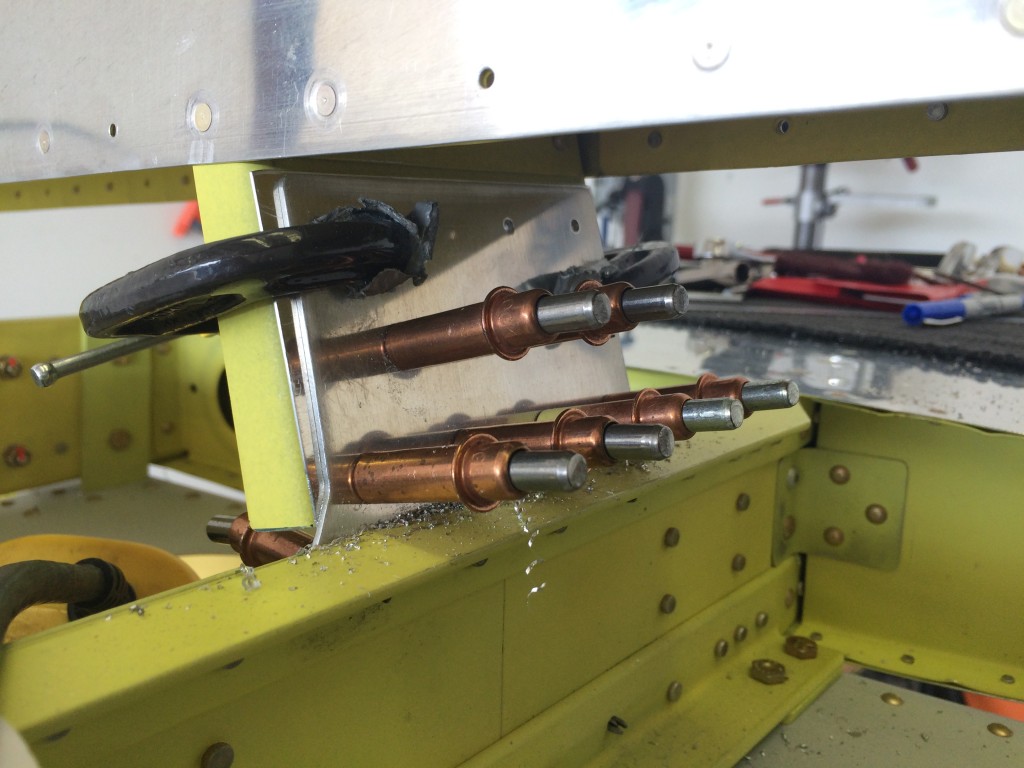

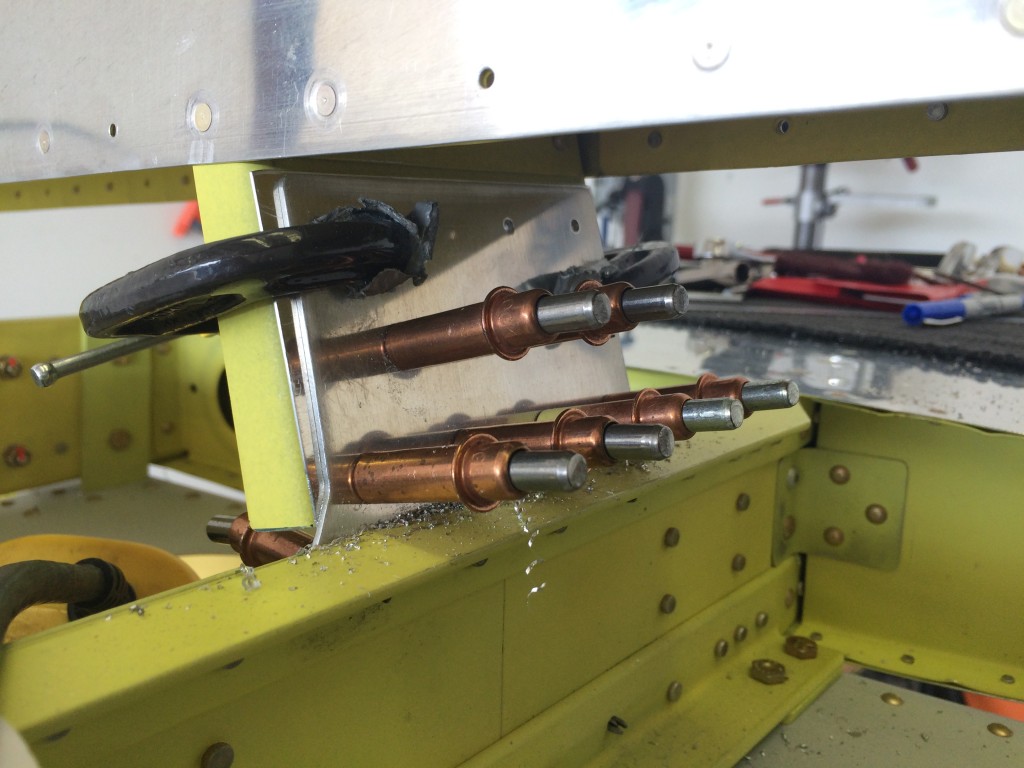

With that gap set, I clamped the fuse bars and rear spar together, and using my Brown Tool drill block, drilled the four #12 holes that hold the assembly together. I use the drill block whenever I can…it works great for getting nice, clean, straight holes.

Here’s everything bolted in place. Look carefully and you’ll see the dimpled heads of the NAS6604 bolts on the front spar.

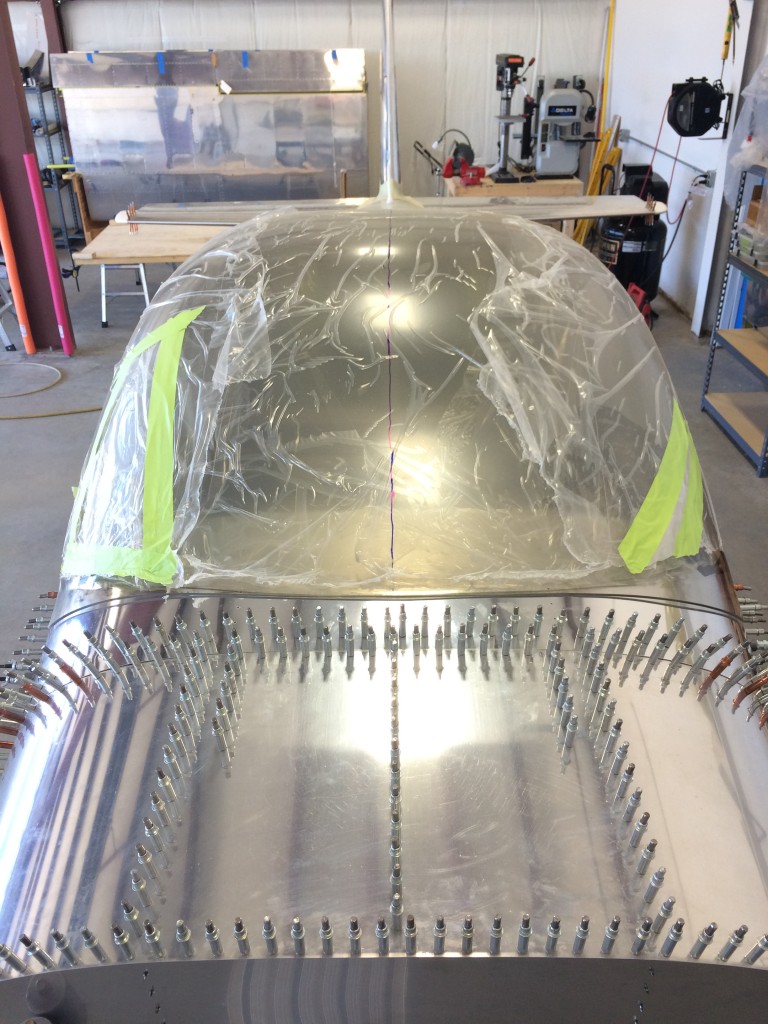

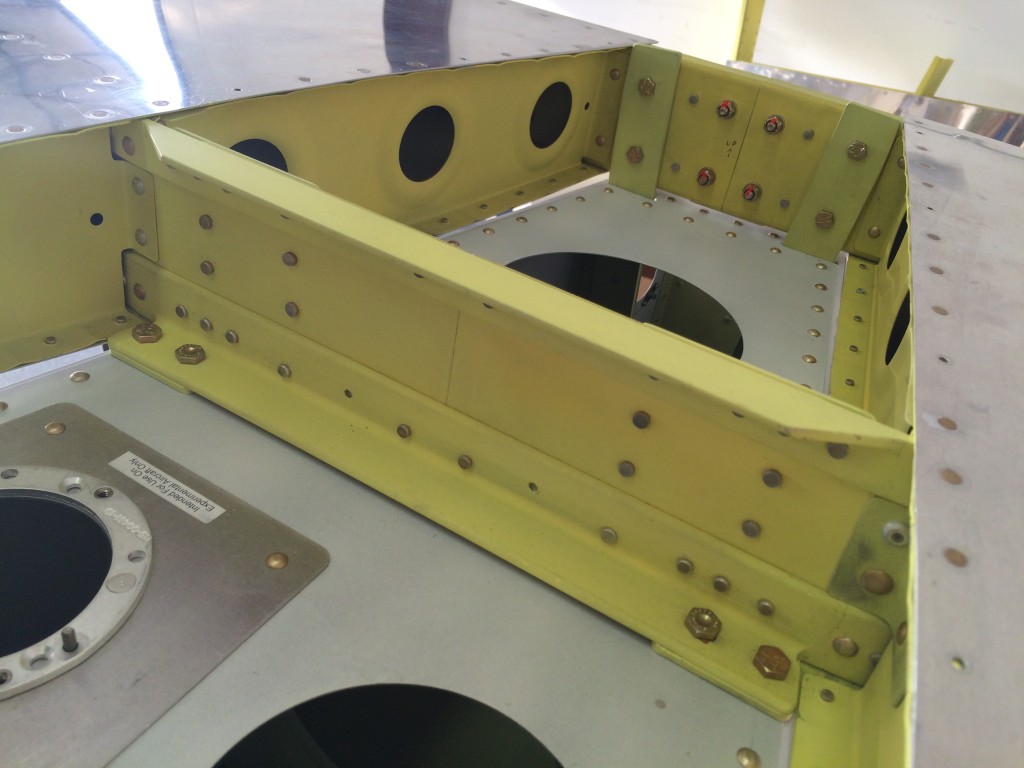

Here’s the HS stab in place. It’s been sitting in storage for ten years…and now it’s part of the airplane. Cool.

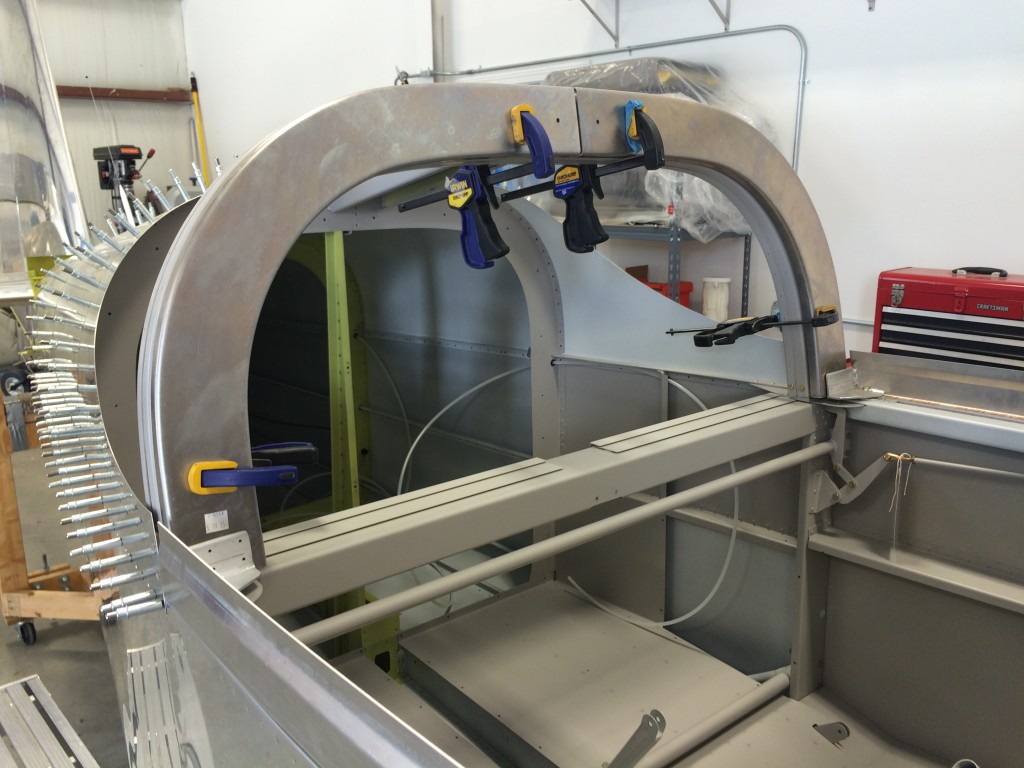

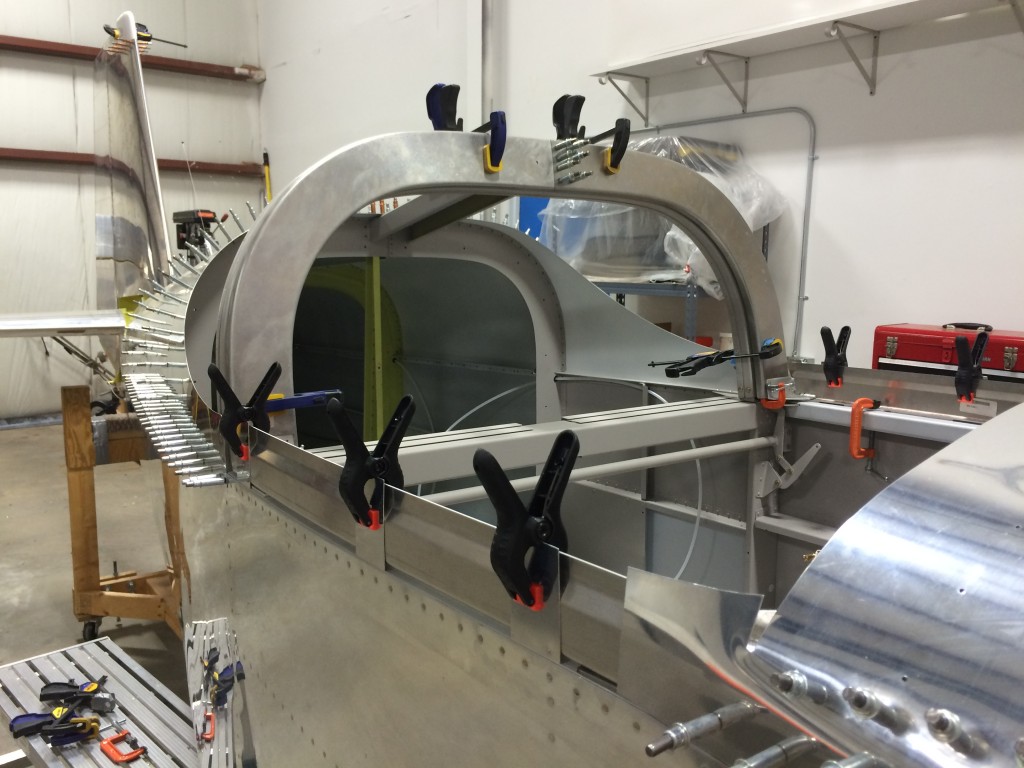

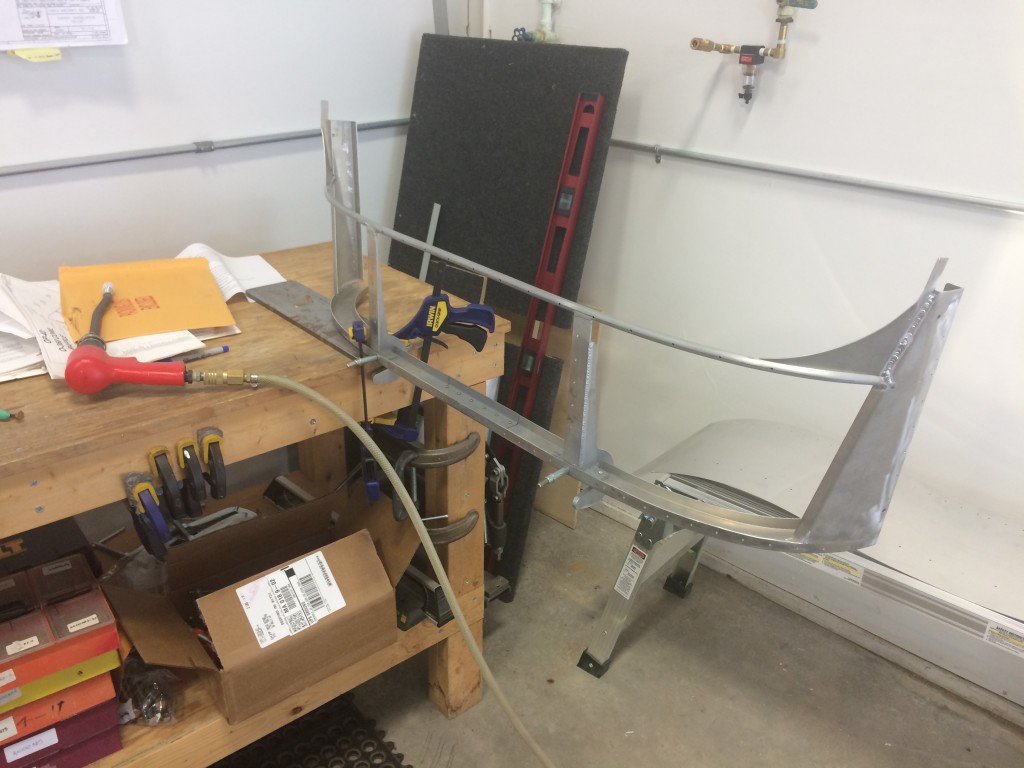

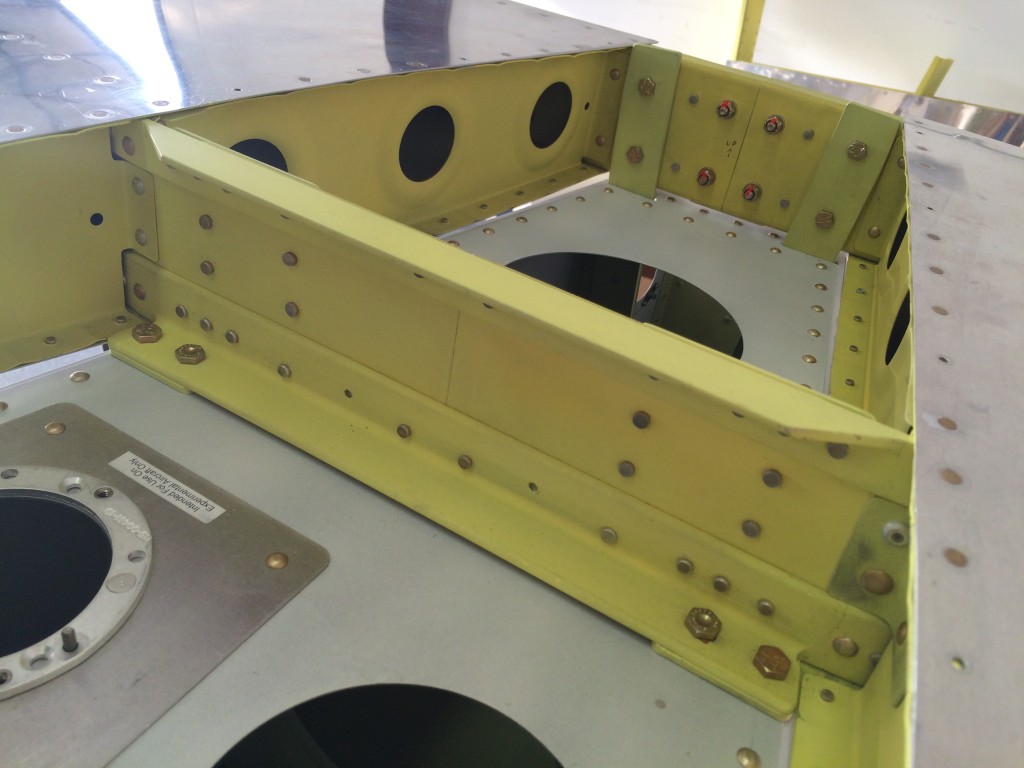

The next step was to attach the vertical stabilizer. There are several steps in this process, and a couple of them were somewhat tricky. Just getting the vertical stab aligned correctly was a challenge – it was tough to get everything clamped in place firmly enough that the vertical stab didn’t shift while measuring its alignment relative to the horizontal stab.

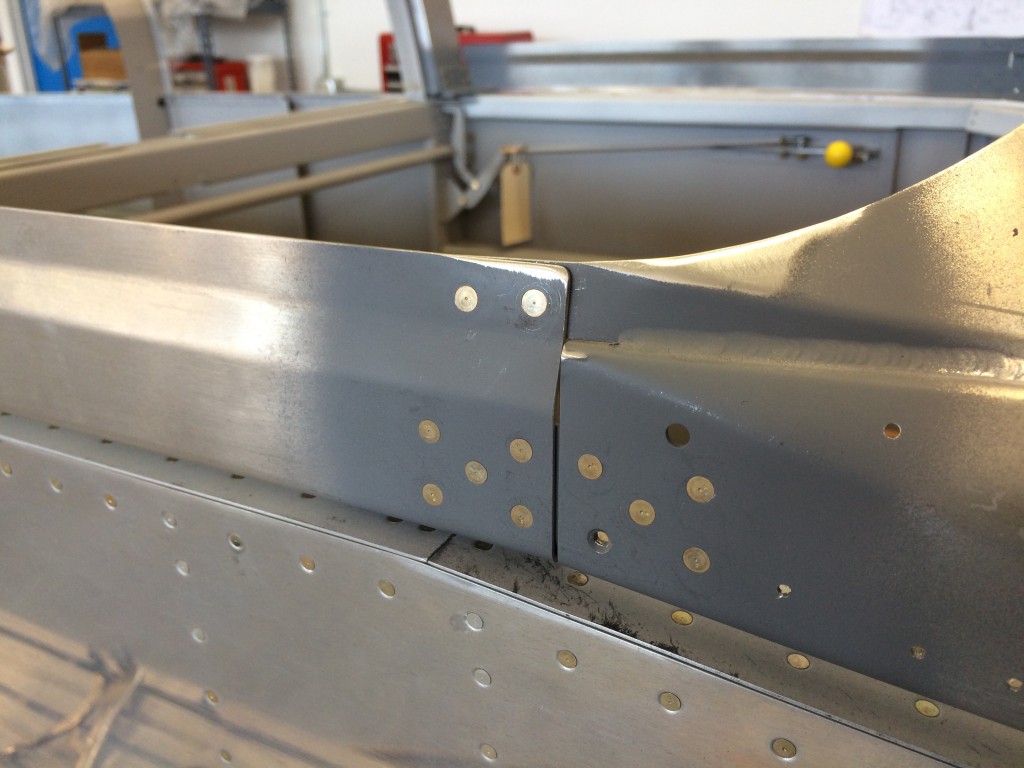

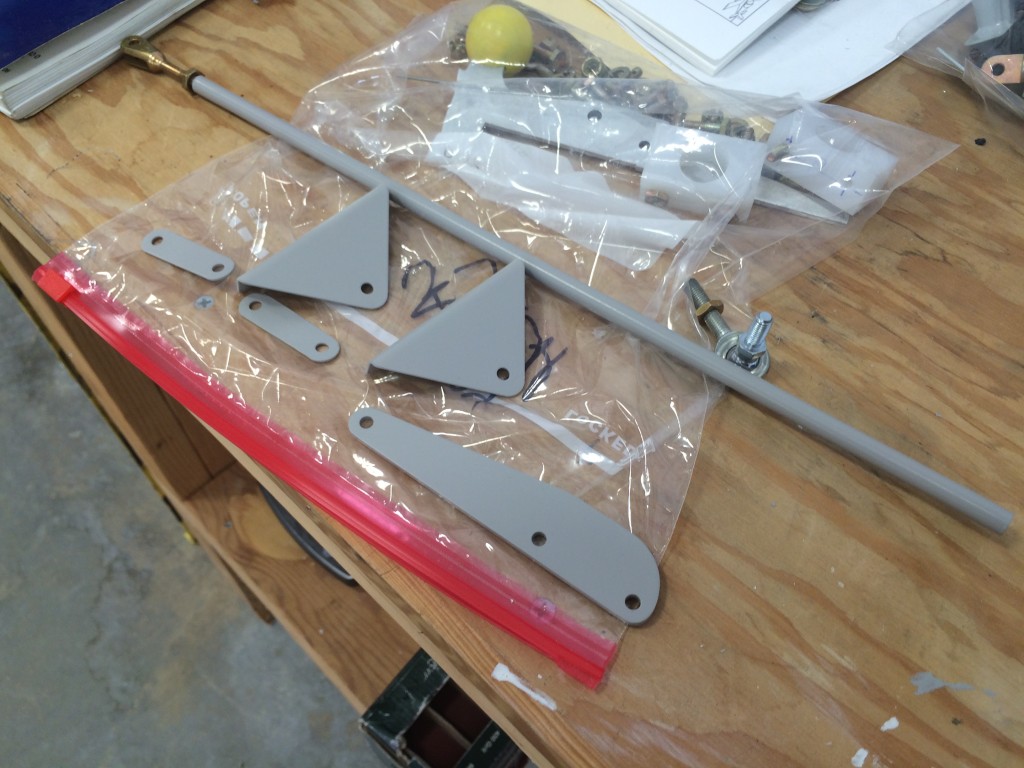

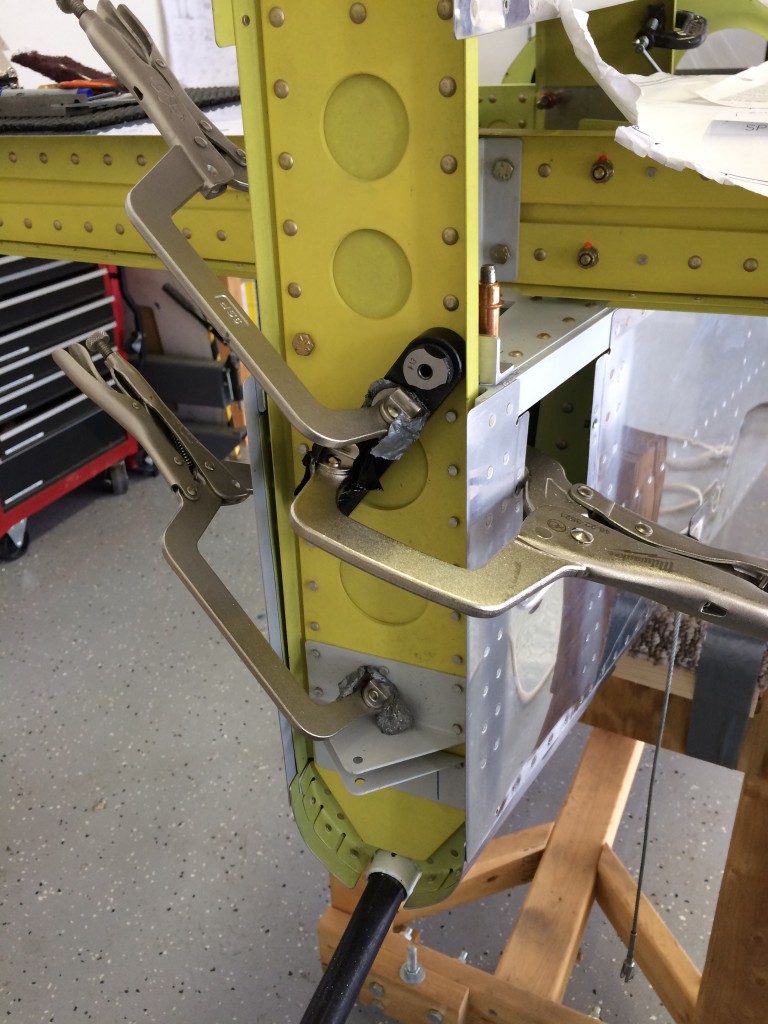

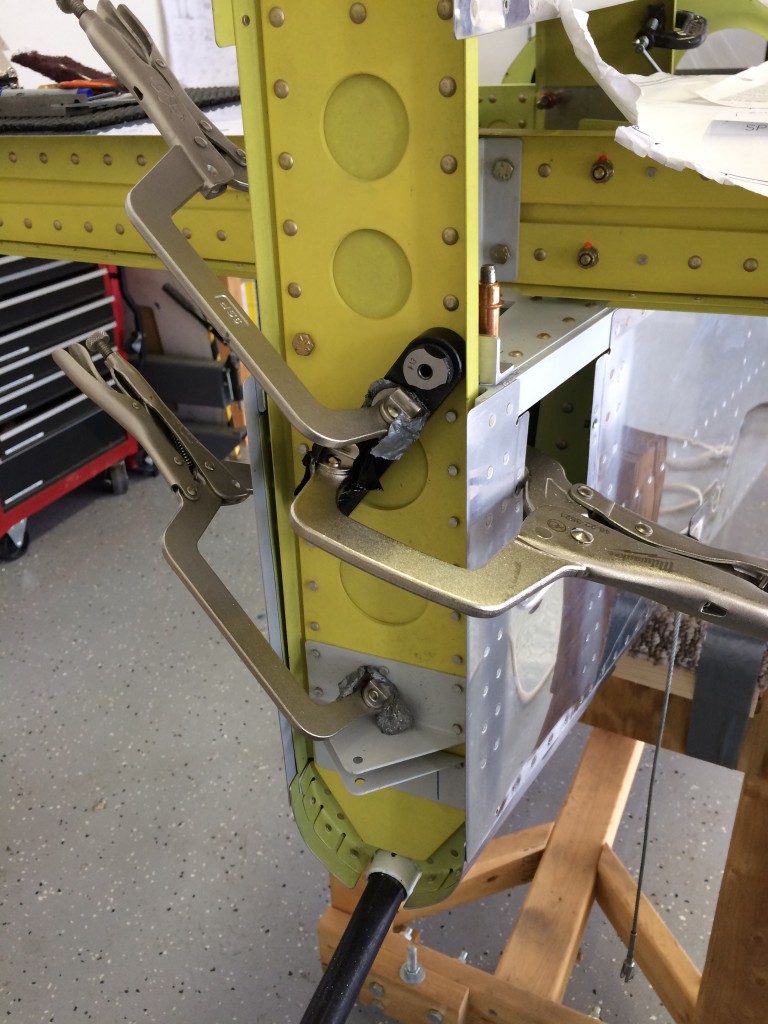

I had already fabricated the upper stab attach bracket and match-drilled it to the fuselage – with the stab aligned I used my trusty drill block and match-drilled the attach bracket to the stab. All those vise-grip clamps I’ve been collecting sure came in handy.

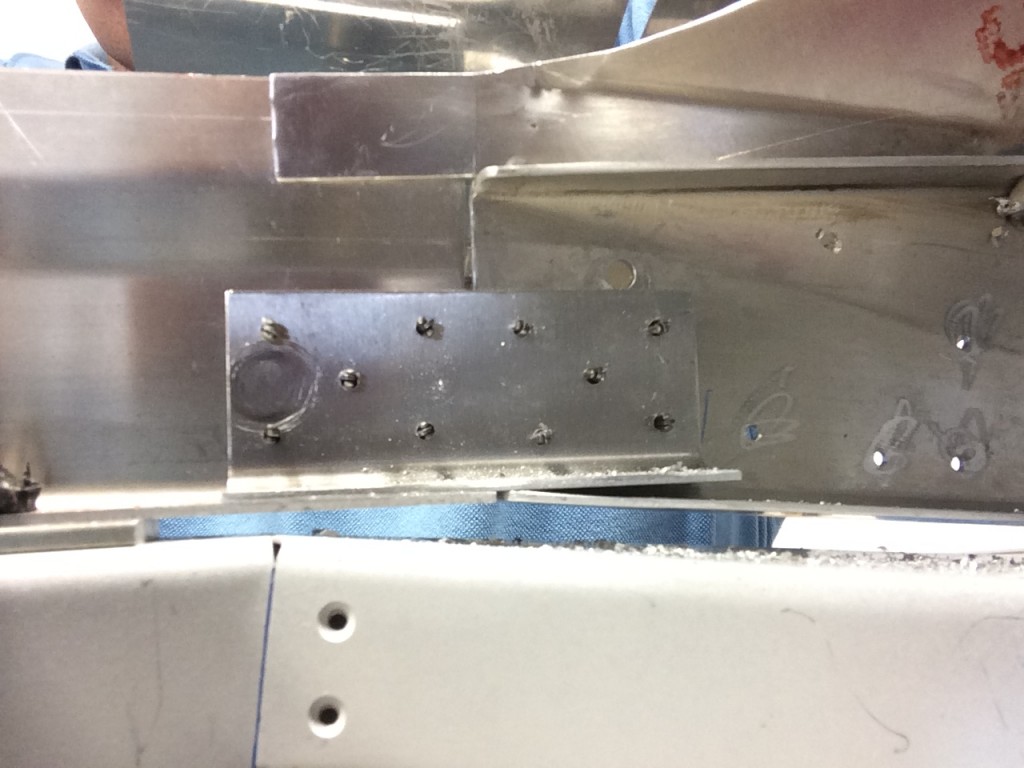

After the upper attach bracket was match-drilled, I fitted the angled attach plate that connects the vertical and horizontal stabilizer forward spars.

After the upper attach bracket was match-drilled, I fitted the angled attach plate that connects the vertical and horizontal stabilizer forward spars.

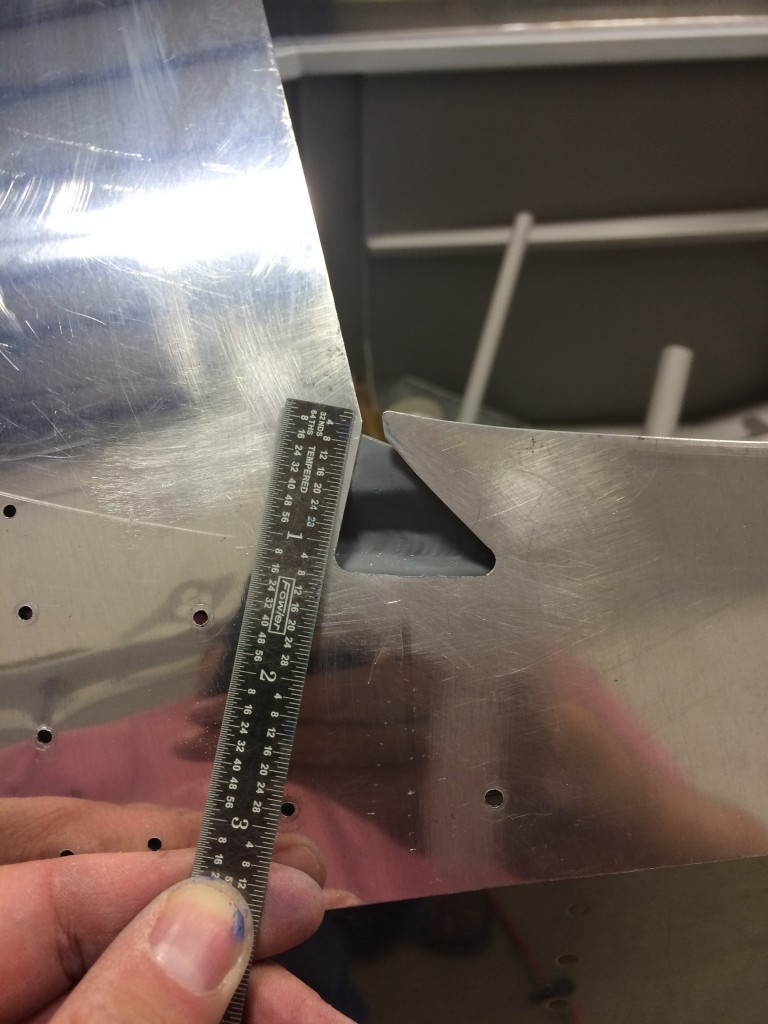

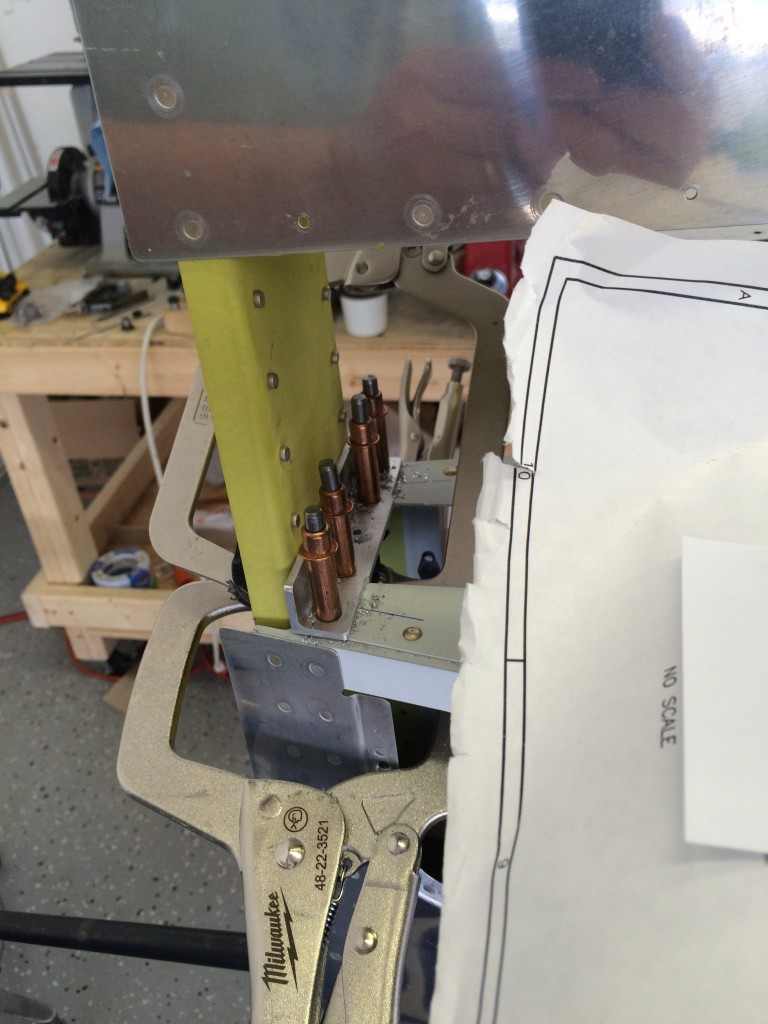

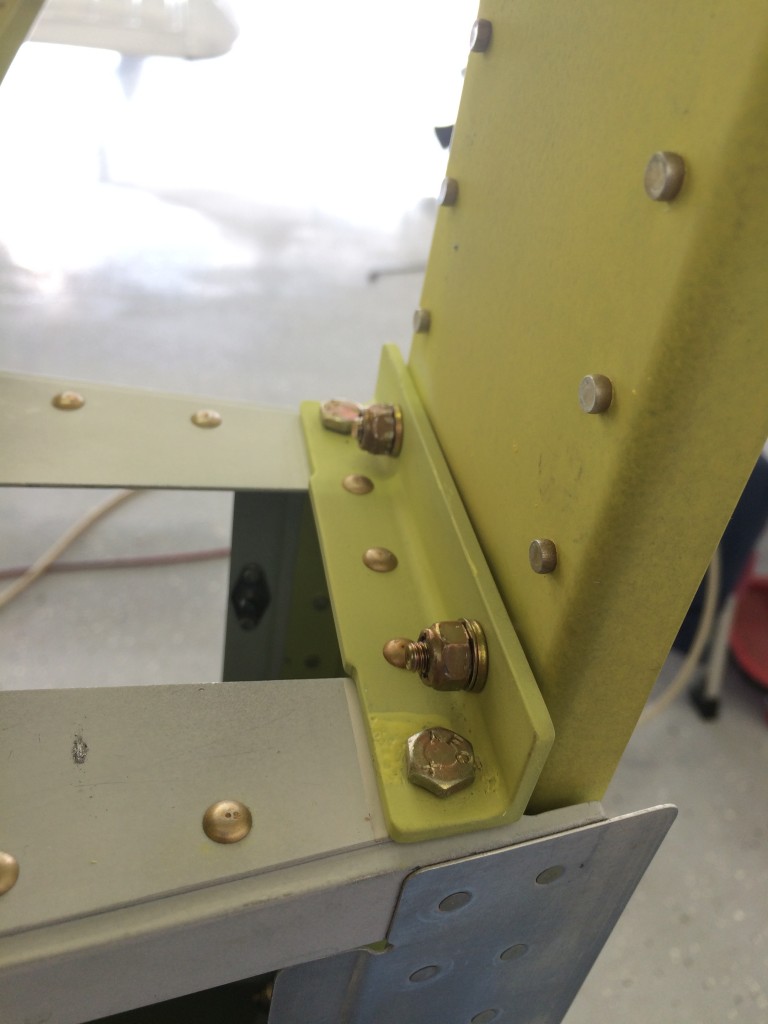

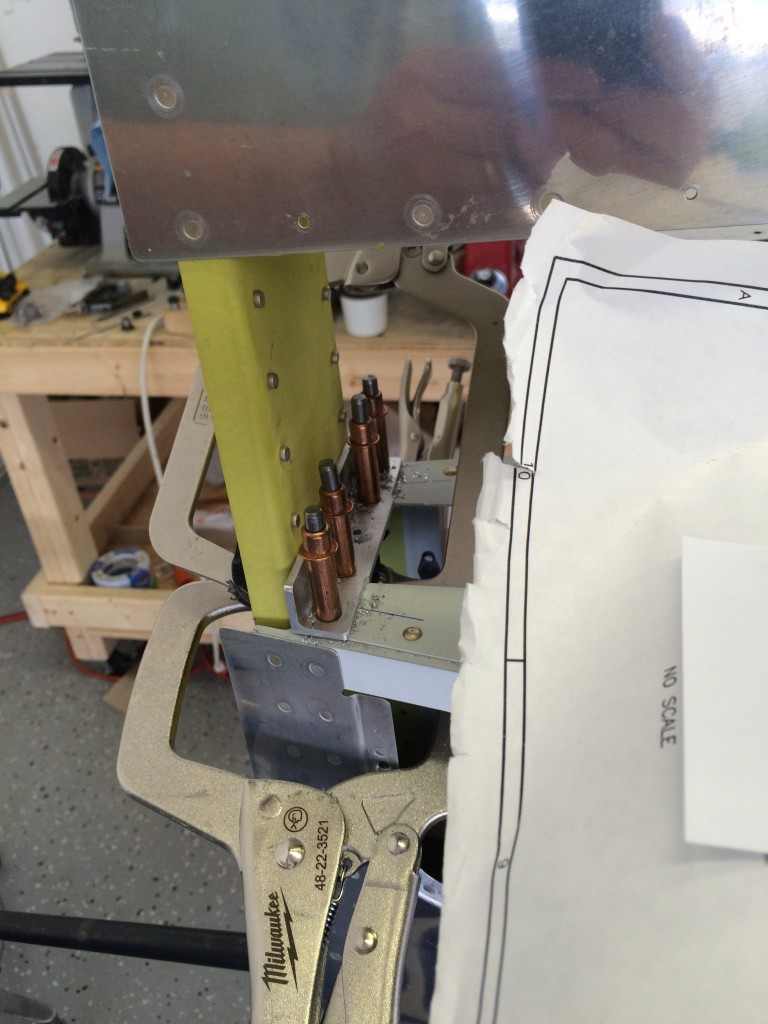

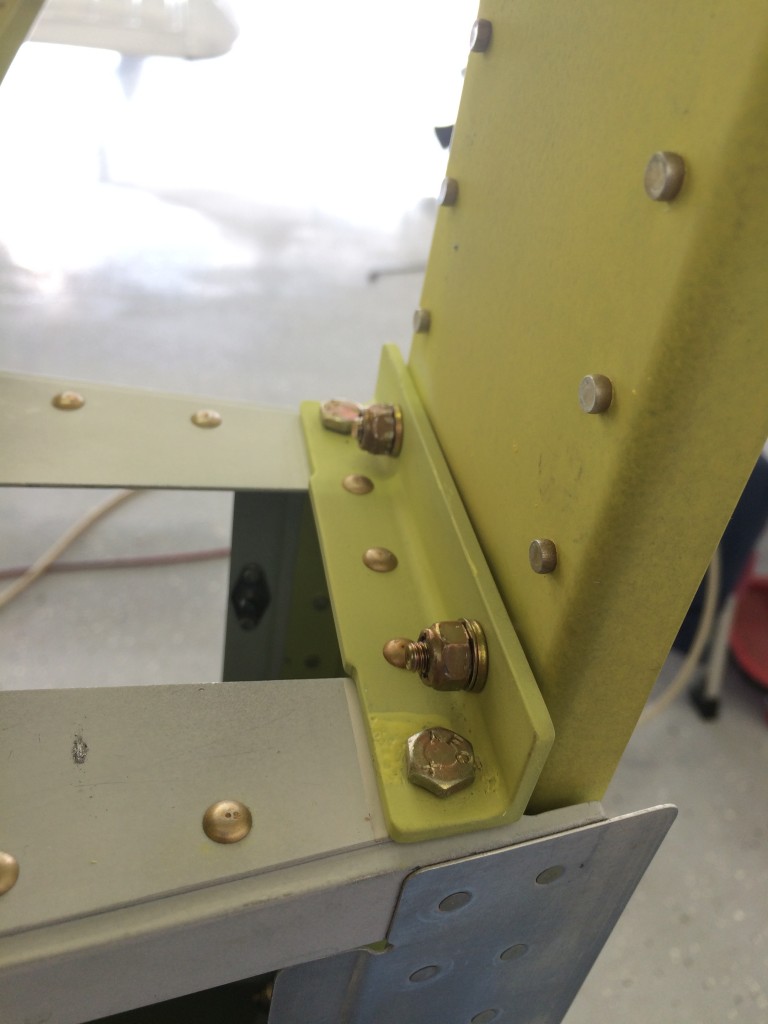

Here I’ve already match-drilled the plate to the horizontal spar – those holes will be opened to #12 – and I’ve started drilling the plate to the vertical spar as well. I had to insert a 0.020″ shim between the plate and spar to improve the fit. The plans tell you to anticipate this, and have dimensions for fabricating a shim if one is required.

Here I’ve already match-drilled the plate to the horizontal spar – those holes will be opened to #12 – and I’ve started drilling the plate to the vertical spar as well. I had to insert a 0.020″ shim between the plate and spar to improve the fit. The plans tell you to anticipate this, and have dimensions for fabricating a shim if one is required.

I used the angle drill sparingly on these holes. Some of them didn’t get final-drilled until I removed the vertical stab for priming.

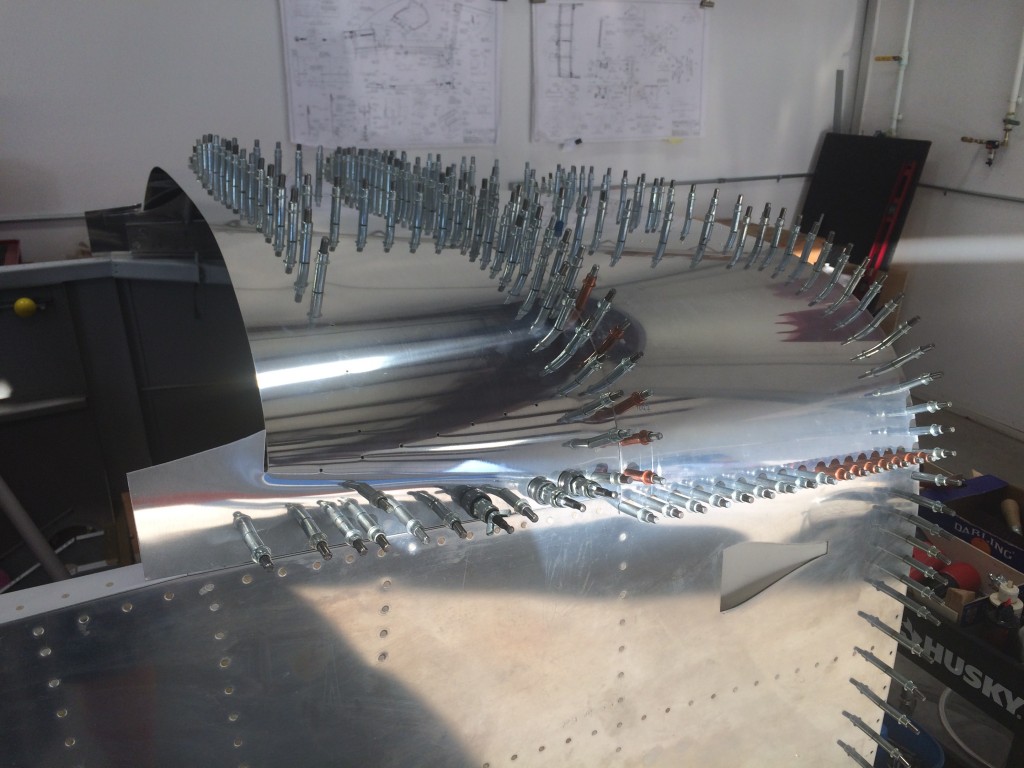

Here’s the vertical stab’s rear spar primed and bolted into place.

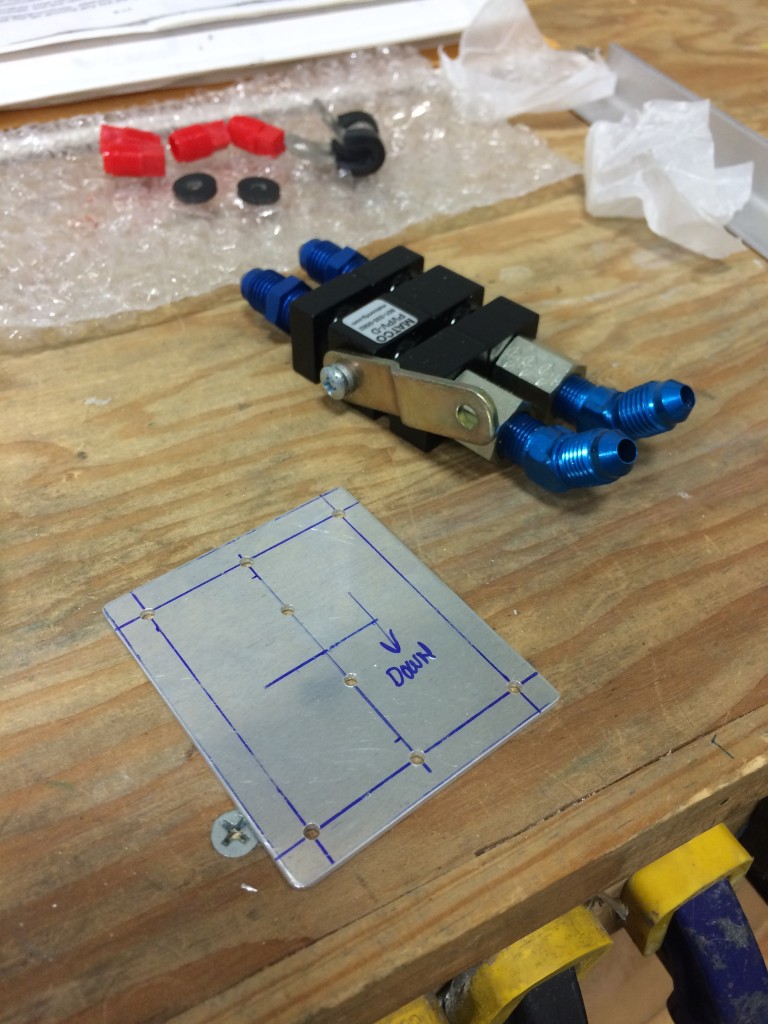

I neglected to take many pictures of the measurement and drilling process for the lower three bolts – they secure the vertical stab lower spar and tailwheel aft attach bracket to the fuselage.

The measurement process was a little tricky – edge distance has to be maintained on the tailwheel bracket and the vertical stab spar, but they’re on opposite sides of the aft most fuselage bulkhead so it’s impossible to directly measure edge distance. The only way I could get this done correctly was to establish a series of reference points for the tailwheel bracket measured from the fuselage sides and aft deck. Those reference points allowed me to project the location of the tailwheel bracket onto the rear side of the aft fuselage bulkhead.

With the vertical stab clamped into place, I was then able to pick hole locations that met all of Vans edge distance criteria. After that, drilling the holes was a piece of cake.

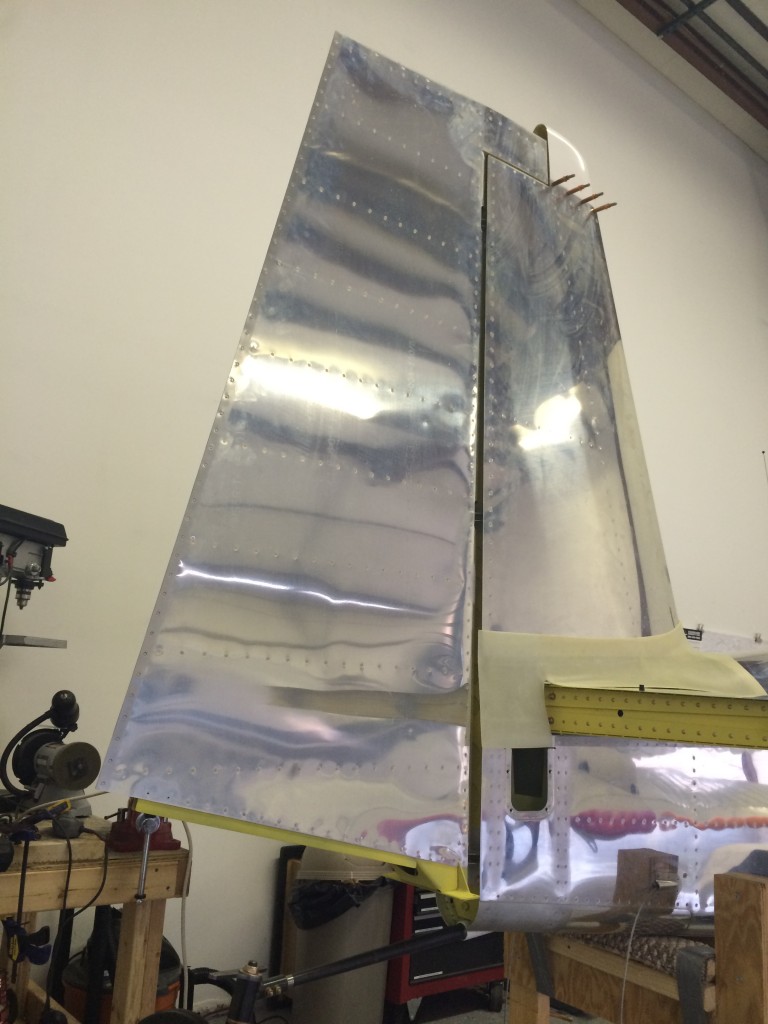

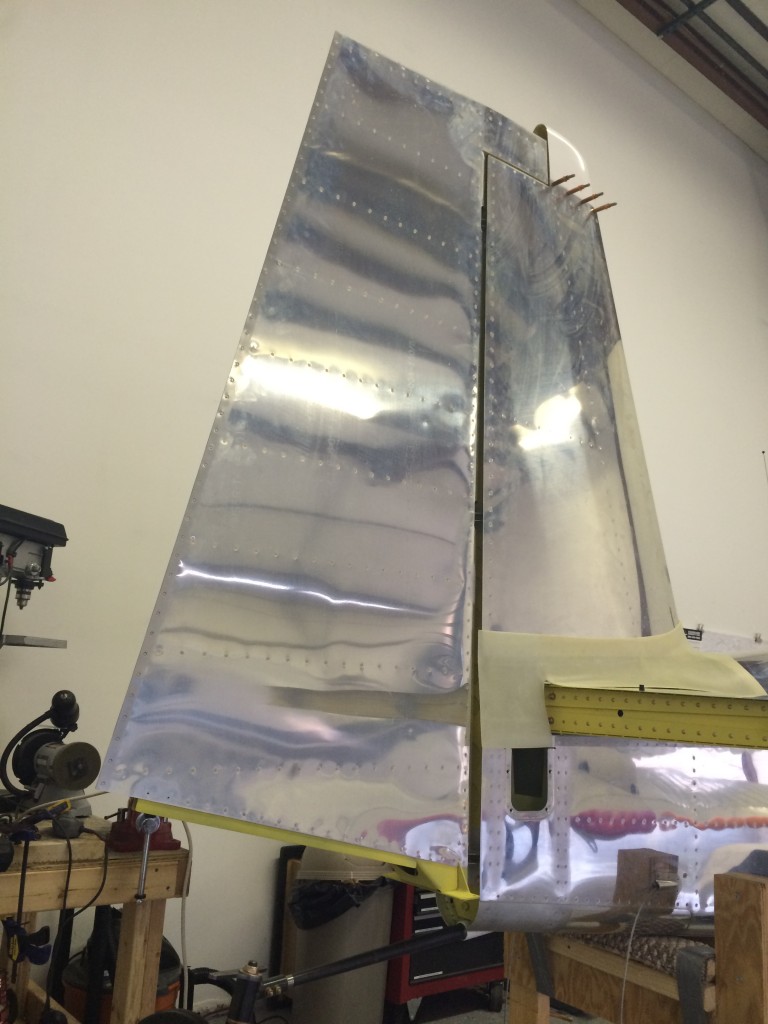

Here’s the vertical stab bolted and torqued into place…very cool.

Another pic? Sure, why not…

And I couldn’t resist temporarily installing the rudder…it’s been waiting a long time to be on the airplane!