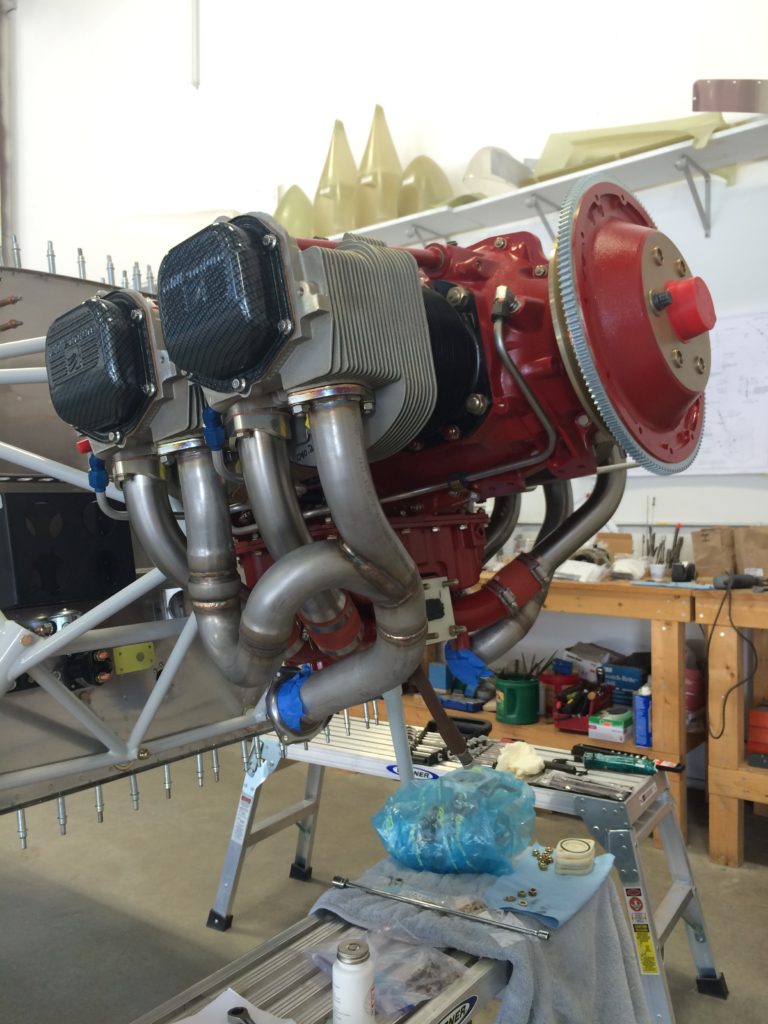

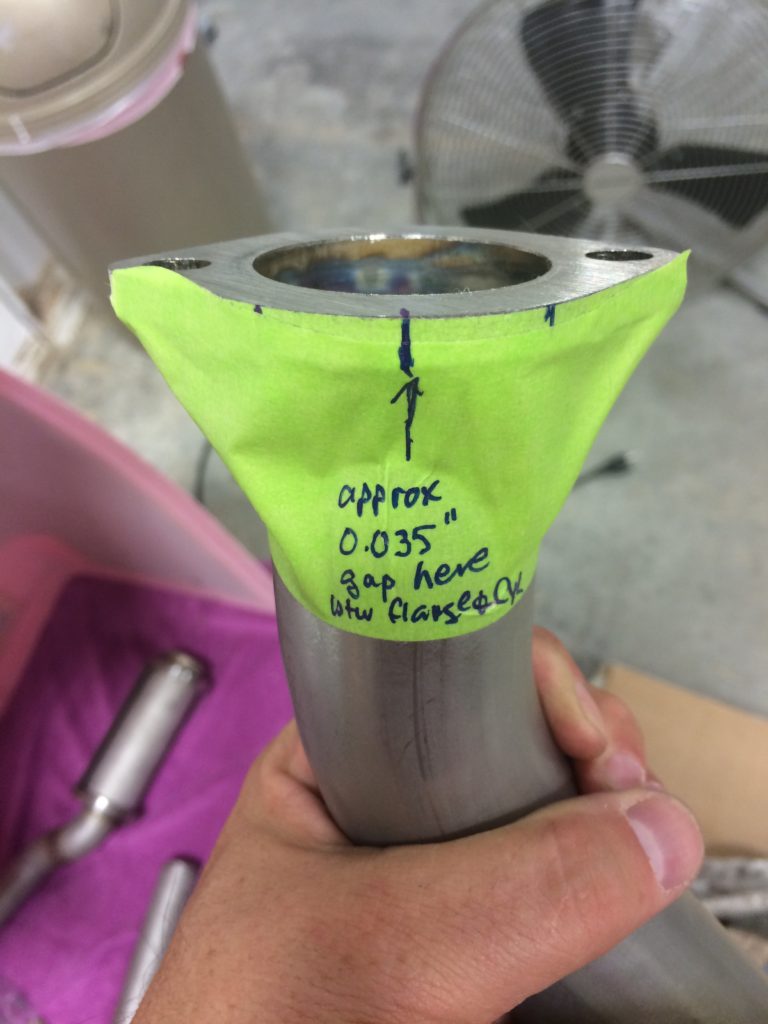

Before fitting the spinner I wanted to have the prop temporarily mounted on the engine. This took a bit of work that happened in parallel with a lot of other tasks. Here are some pics, with words to follow later.

Taking a breather

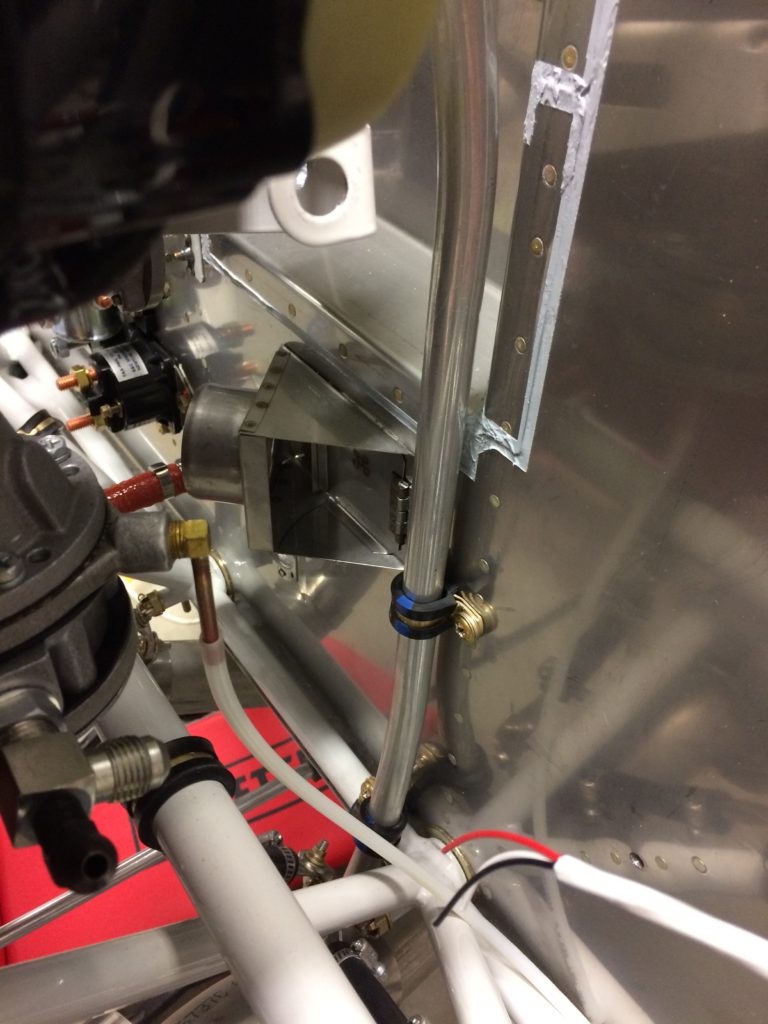

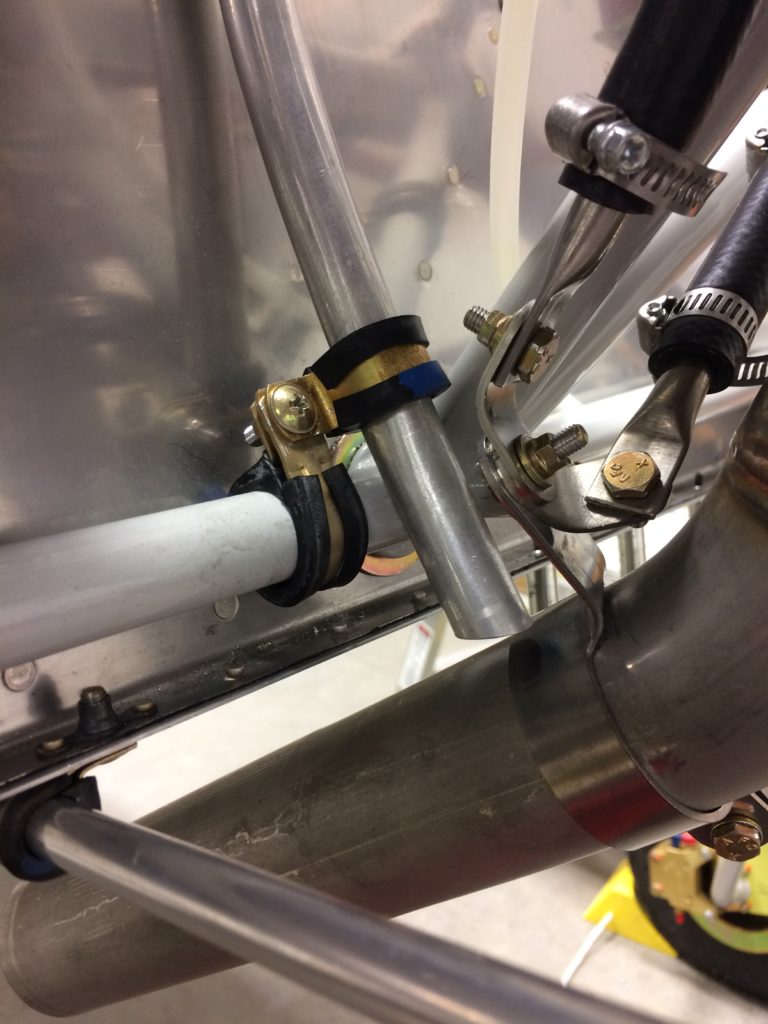

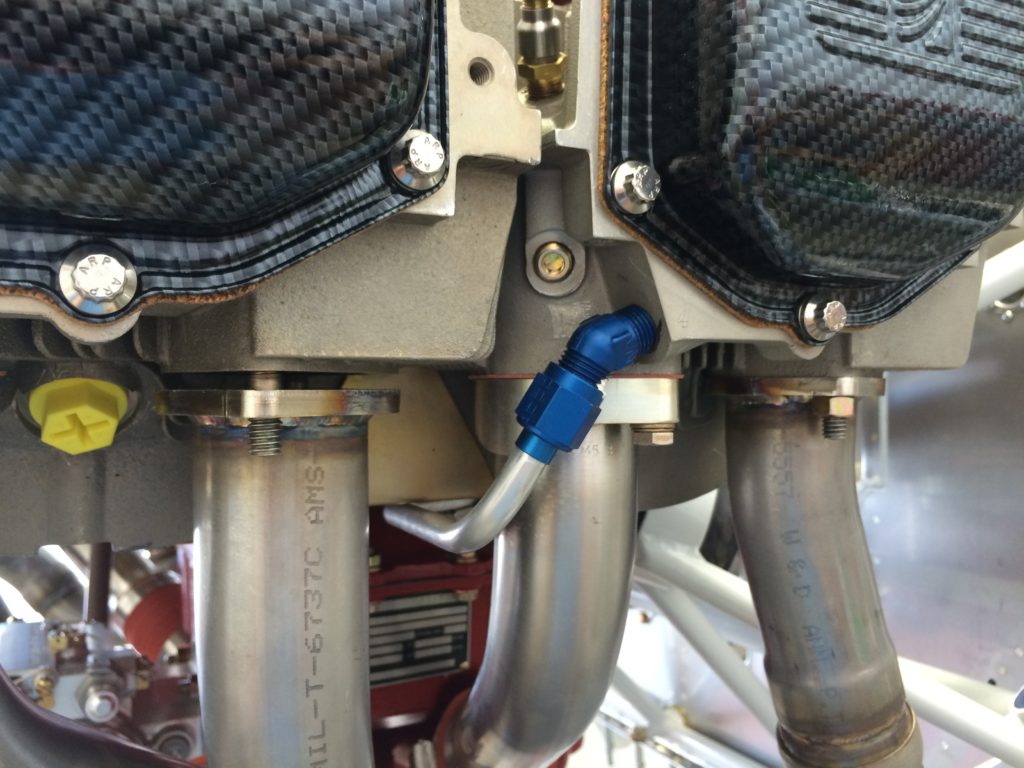

Finishing up the exhaust

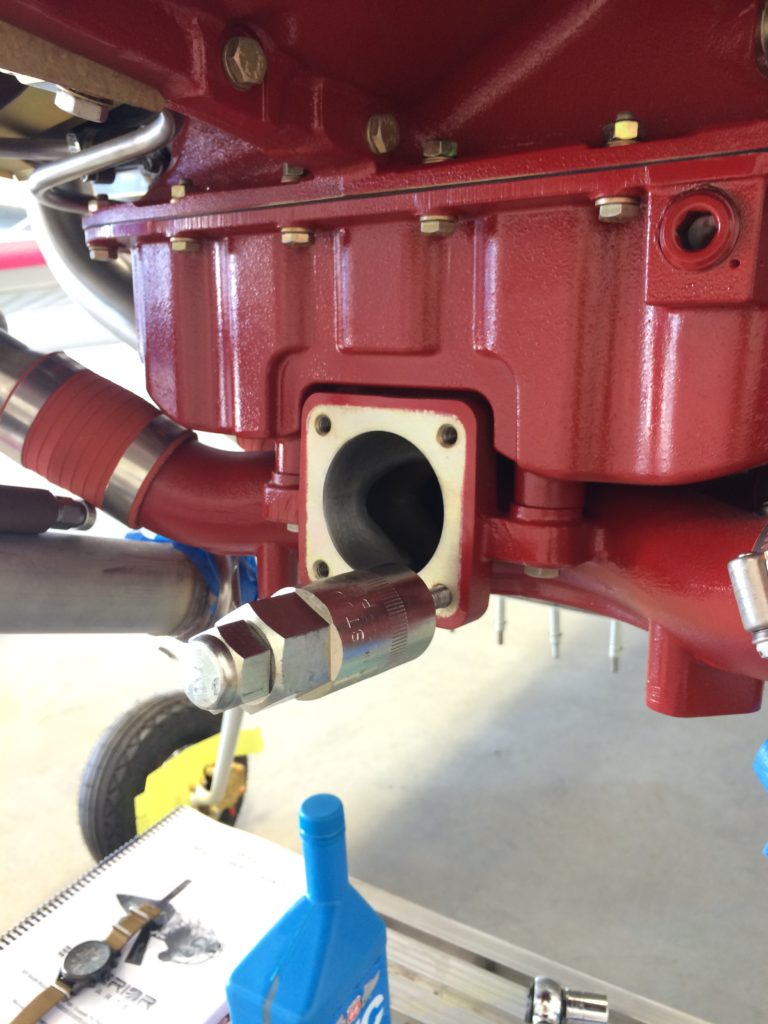

Tearing a new orifice

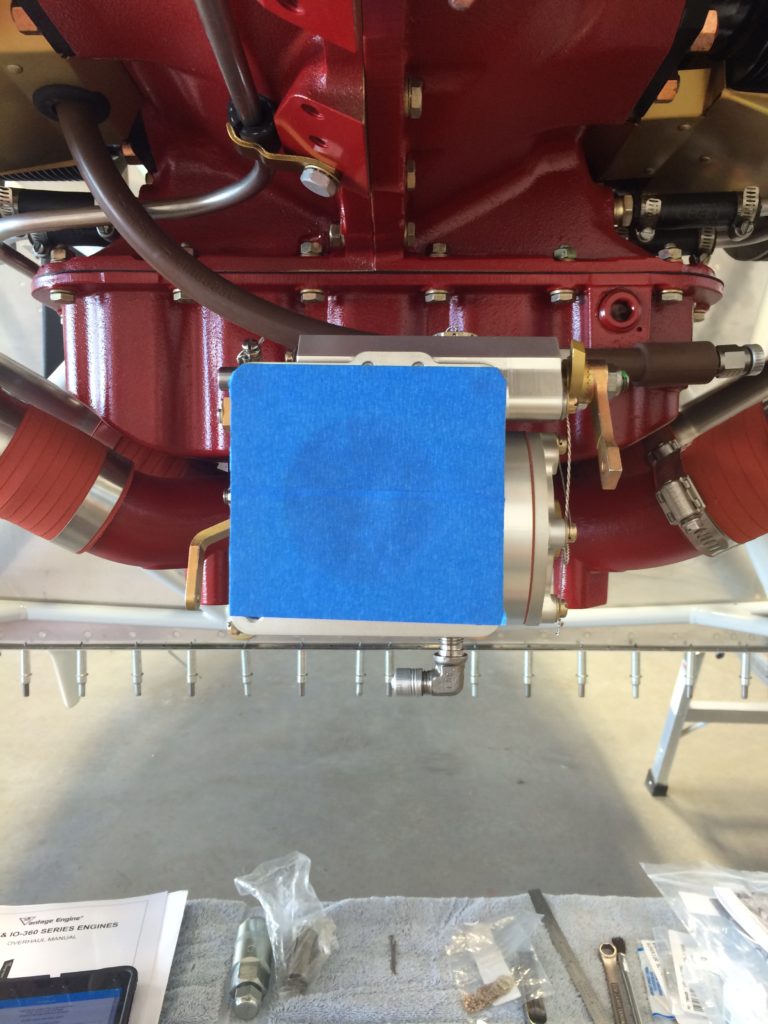

Racking and stacking

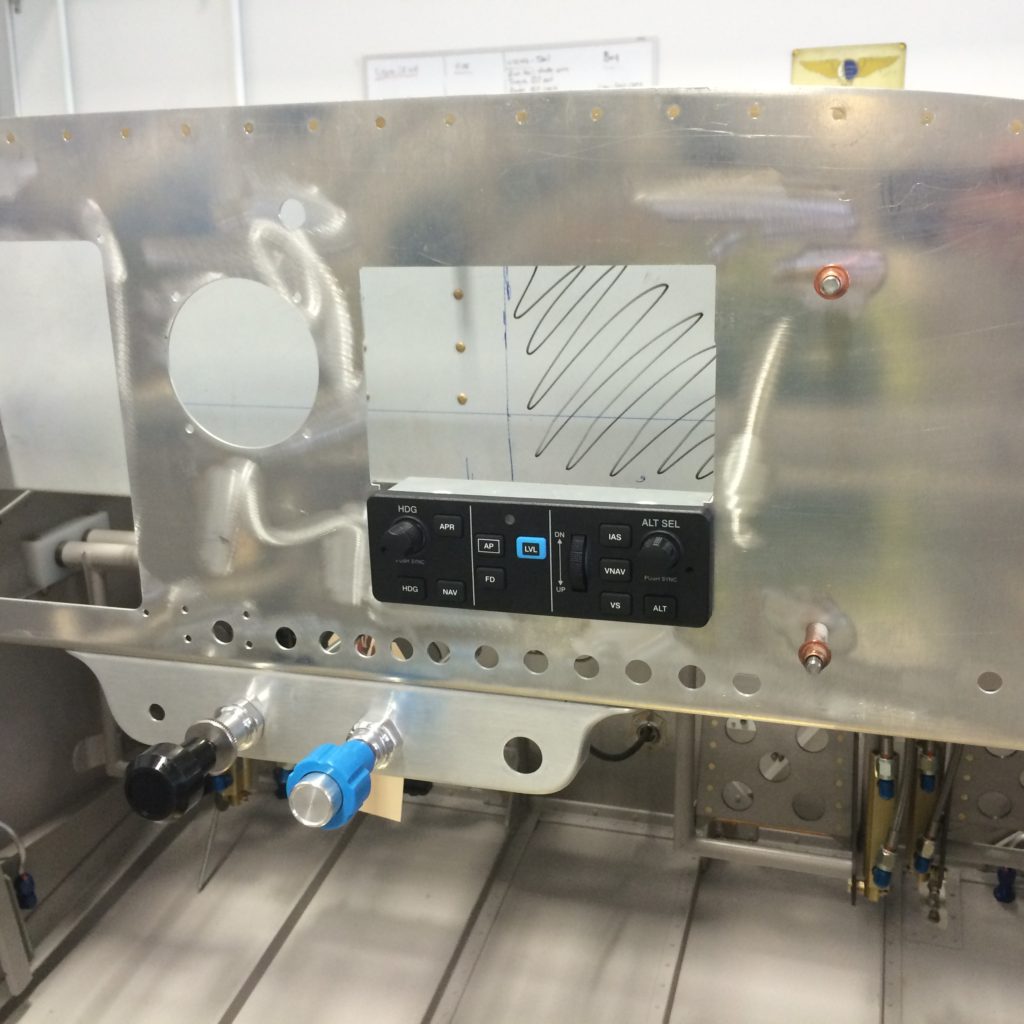

Getting a little frustrated with tweaking engine stuff, so in preparation for permanently installing the subpanel I started working on fitting the avionics racks.

The GMC-307 autopilot controller was easy.

Wasn’t so easy to get a correctly-aligned hole in the subpanel to accommodate the GTN-650 rack (the comm/WAAS GPS/VOR/localizer/ILS does-everything box).

Also had to make sure the GTN-650 and GMA-245 (that’s the audio panel) racks were correctly spaced from each other.

Took a lot of filing and fitting to get to this point. The rear rack mount “ears” are actually riveted to two 0.063″ angles that will be held in place by nutplates. I would’ve preferred just to attach them to the front side of the subpanel, but the rack attachment fasteners are too close to the subpanel to allow that.

A nice bit of visual progress, don’t you think?

I have no clever title for this throttle bracket post

Two steps forward, one step back

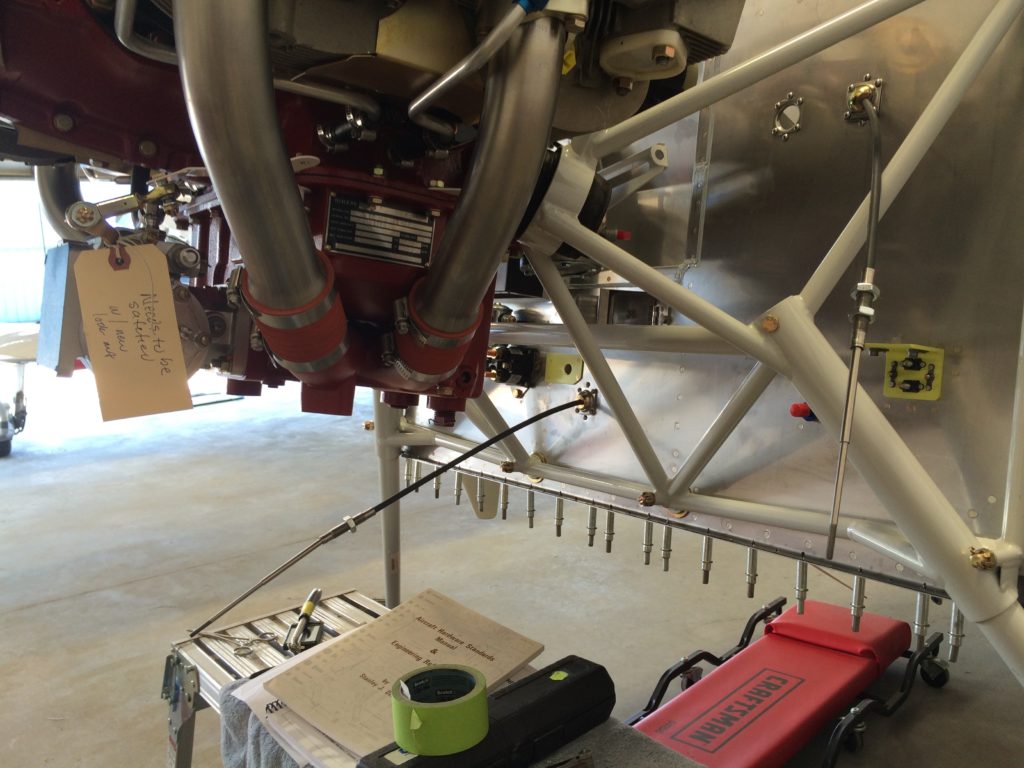

The last really big check

…I hope.

I wrote it to Tim Hass and the folks at Approach Fast Stack for a Garmin 10.3″ G3X Touch EFIS system with Sirius XM, GTN-650 GPS/Nav/Comm, GTX-45R ADS-B In/Out transponder, GMA-245 audio panel, GMC-307 autopilot mode controller, two GSU-28 autopilot servos, and all the associated Garmin boxes that go into a G3X installation.

All these gadgets will be connected to one of Tim’s Fast Stack Pro-X hubs, which will make wiring significantly easier and neater.

It’s worth the (relatively) few extra dollars to speed up avionics installation, and the resulting product will be a lot easier to upgrade should I ever want to.

Two really expensive boxes…

…and their contents.