Ok, I was wrong – there were a couple of other things to do before the wings come off, and fitting the fuel tank vent lines was one of them. Fortunately, these are some of the easiest lines to fabricate. Sorry, only one picture…so not much to report here.

Finishing the tank support brackets

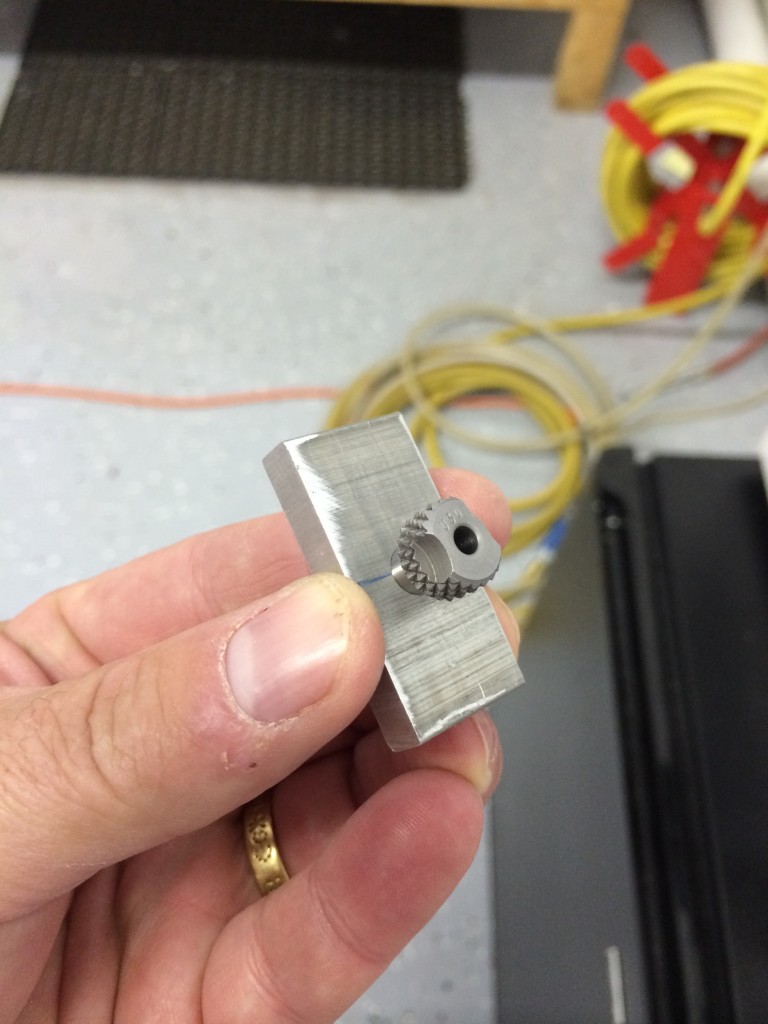

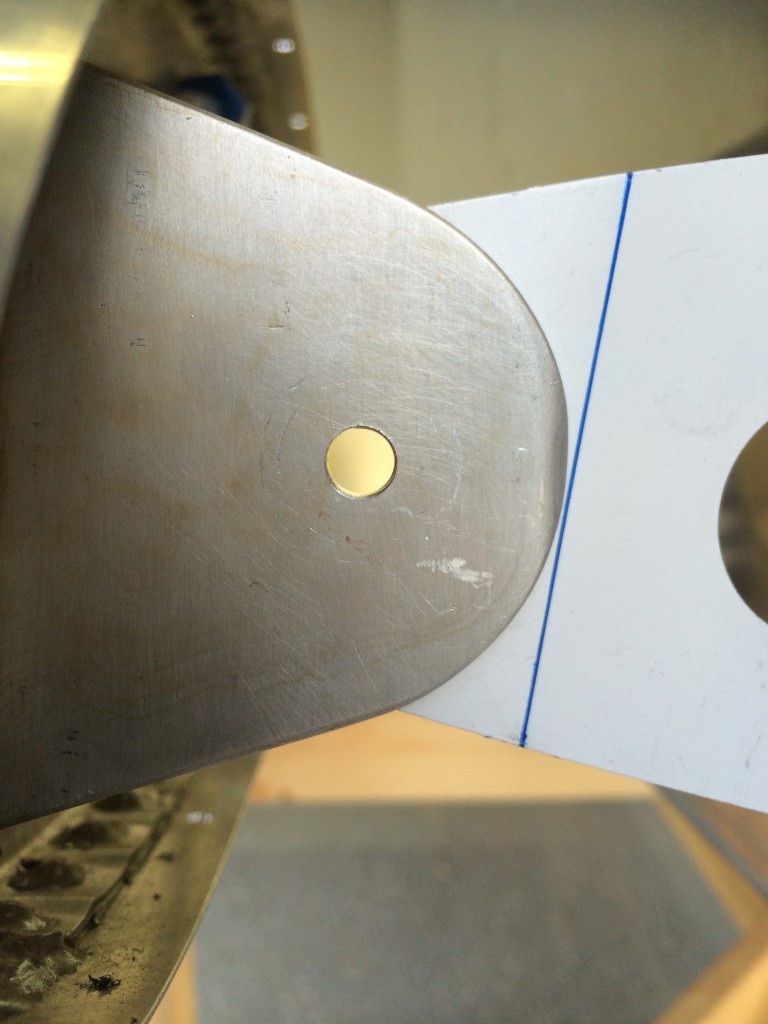

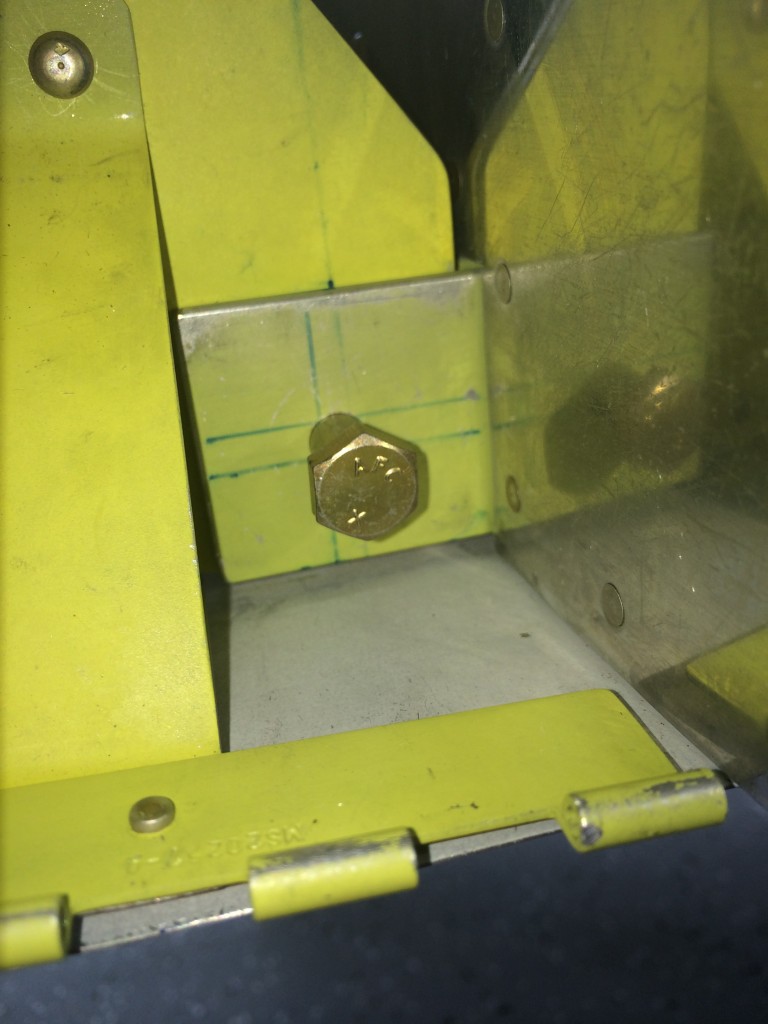

One more task on the tank support brackets – drilling holes that accommodate the bolts that attach the tank support brackets to the tank flanges. I copied an idea from fellow builder Mike Bullock and used a 1/4″ OD drill bushing to drill a #40 pilot hole in the tank angle. The bushing fits snugly in the 1/4″ cutout on the tank support bracket, ensuring that the hole is nicely centered.

Here’s the bushing clamped in place on the aft side of one tank bracket…

I then used the #40 hole to center a 1/4″ drill bushing on the front to the bracket, held in place by a piece of 0.25″ aluminum bar.

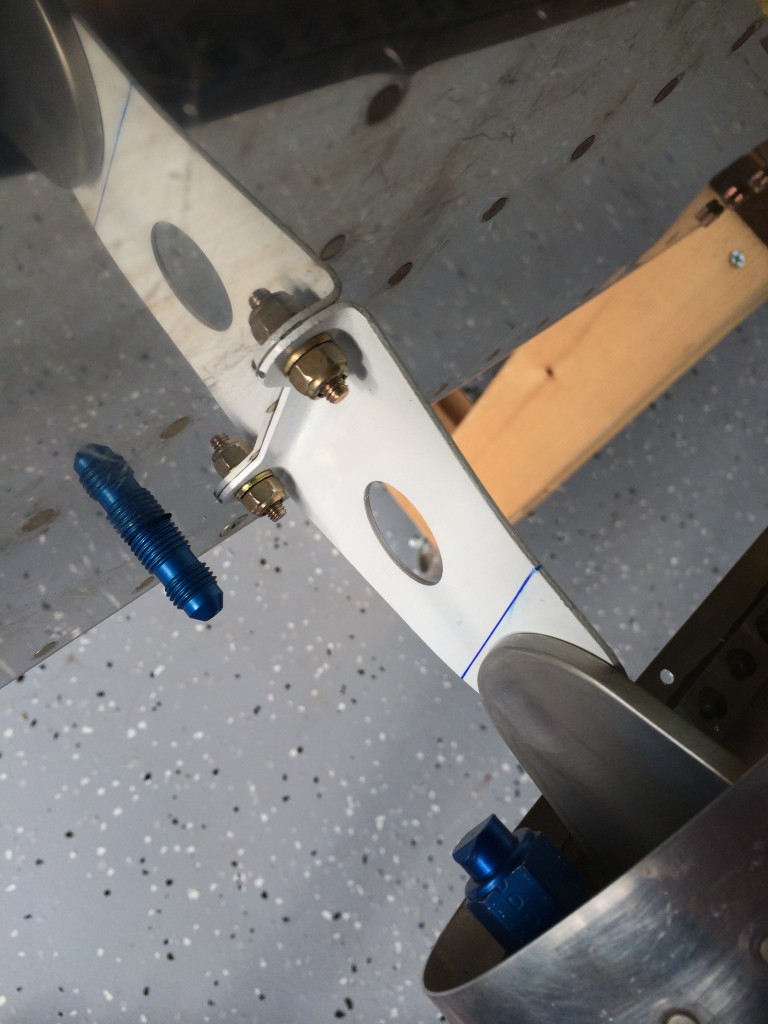

Here’s the final result…both sides came out pretty nicely. A 1/4″ bolt slips neatly into place.

I screwed up a little and didn’t lay out the orientation of the platenut that gets riveted to the tank angle – I’ll have to take care of that when the wings go on for final assembly.

I screwed up a little and didn’t lay out the orientation of the platenut that gets riveted to the tank angle – I’ll have to take care of that when the wings go on for final assembly.

Fun with flaps

Got the flaps rigged and the electric motor connected…time for some fun! Click on the video below to see.

Fitting the tank support brackets

I was a little nervous about fitting these two steel brackets that support the forward inboard end of each fuel tank, because I slipped up and had already fitted them to the fuselage before installing the wings. The brackets are supposed to be clamped to the tank angles – the big D-shaped piece of aluminum on the end of the tank – then match-drilled to the fuse. I was concerned that they might end up being misaligned, but fortunately that turned out to not be the case.

The right bracket fit almost perfectly after being bent according to plans. A little adjustment with the vise and hand seamers got it just right…

The right bracket fit almost perfectly after being bent according to plans. A little adjustment with the vise and hand seamers got it just right…

The left bracket wasn’t quite so easy to fit…I had to tweak it a bit to get it flush with the tank angle, but in the end it came out fine.

Rigging the flaps

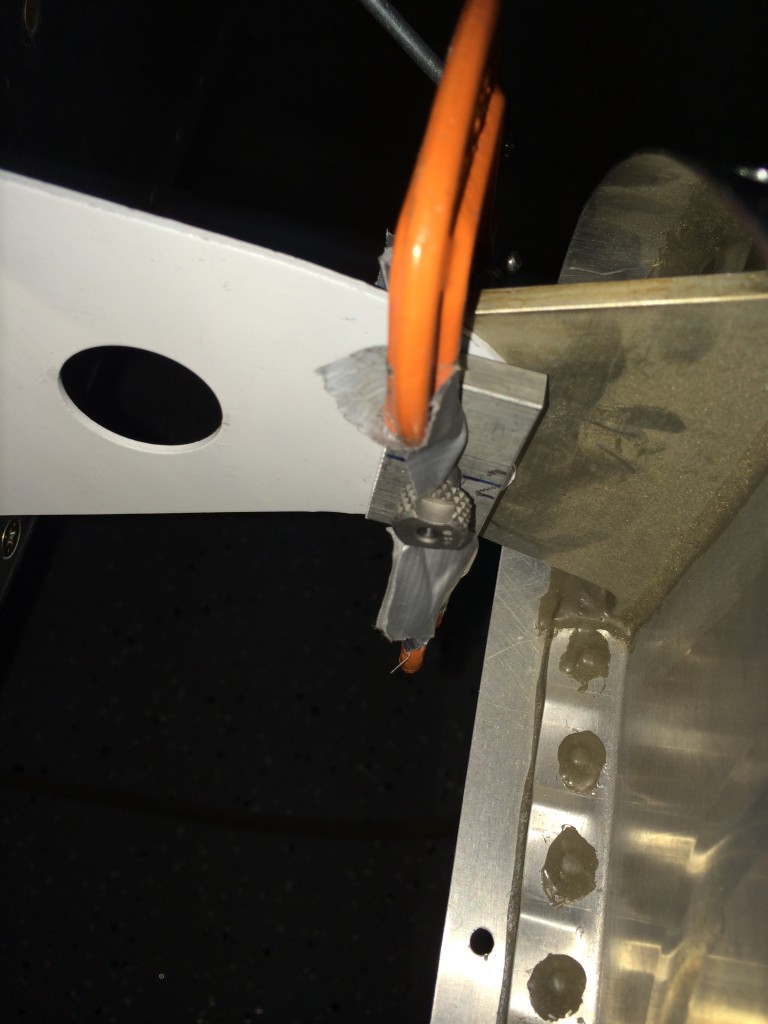

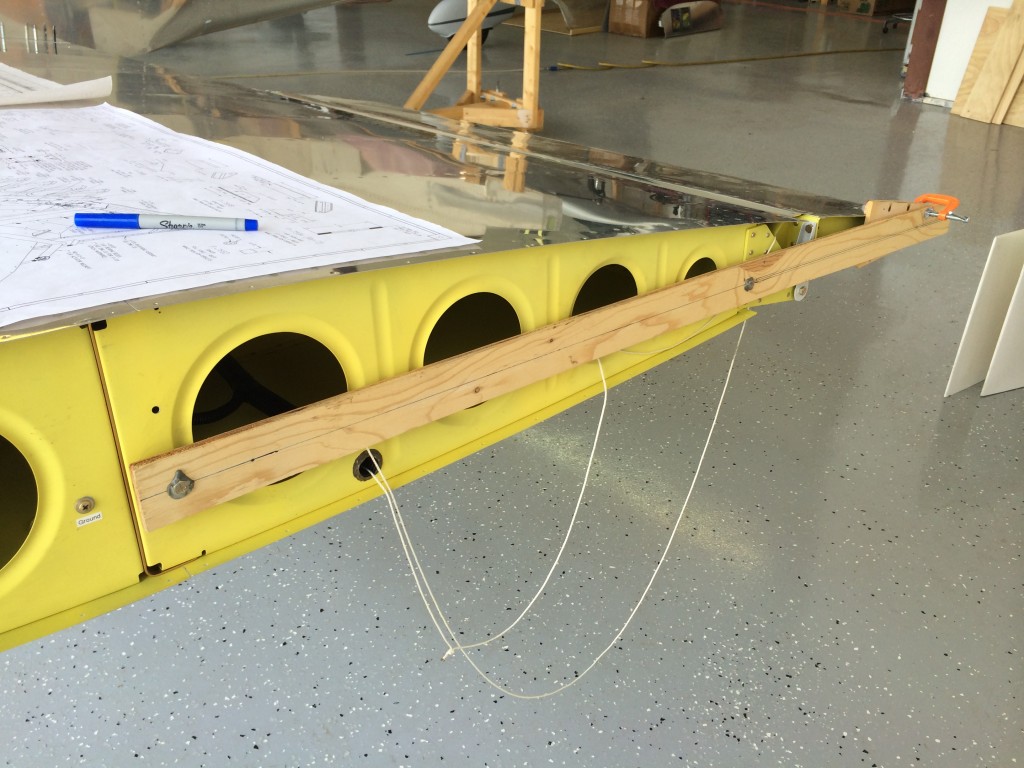

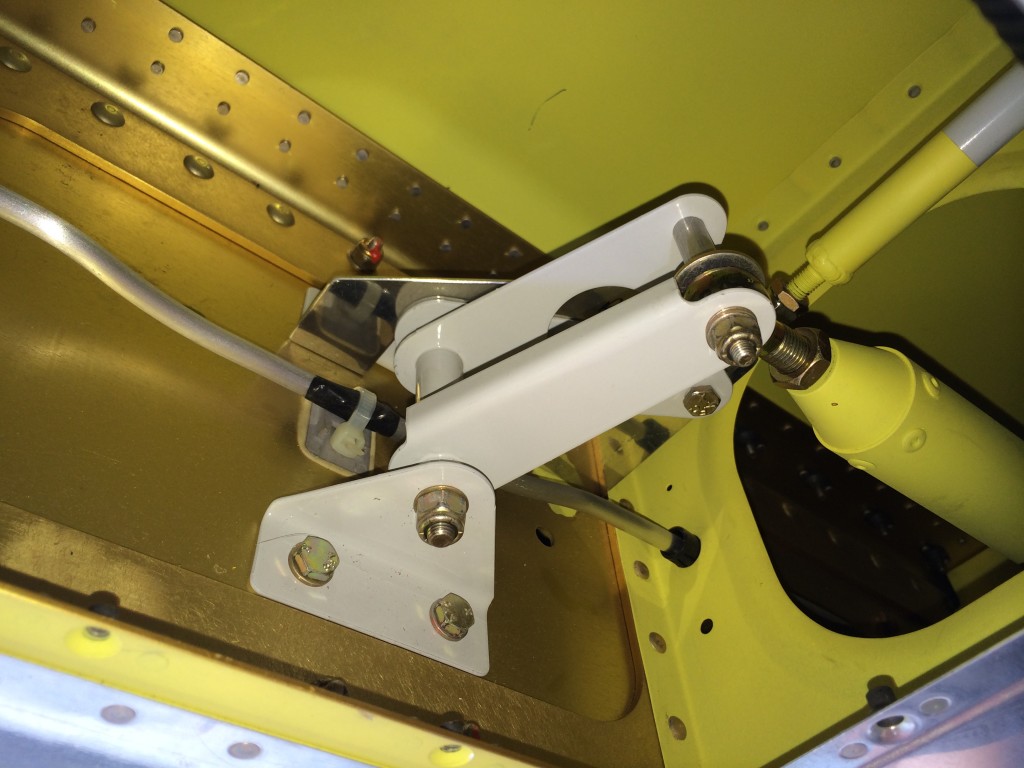

The last major task I had to take care of with the wings installed was rigging the flaps. To do that, I temporarily installed the flap motor and flap actuator arm.

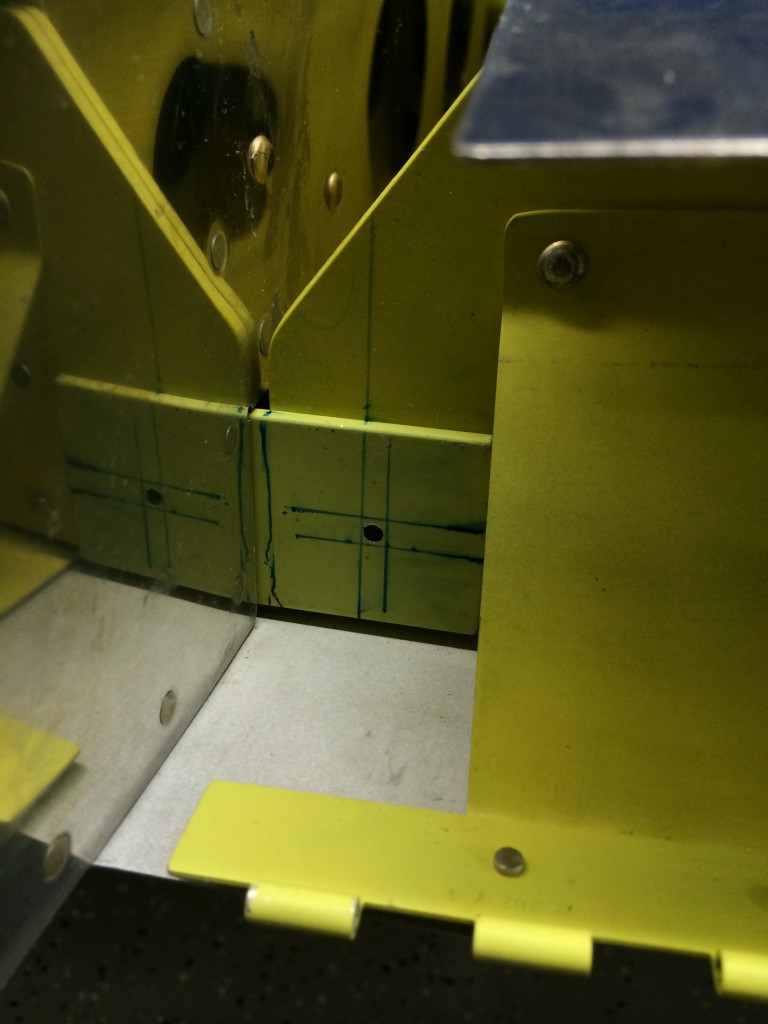

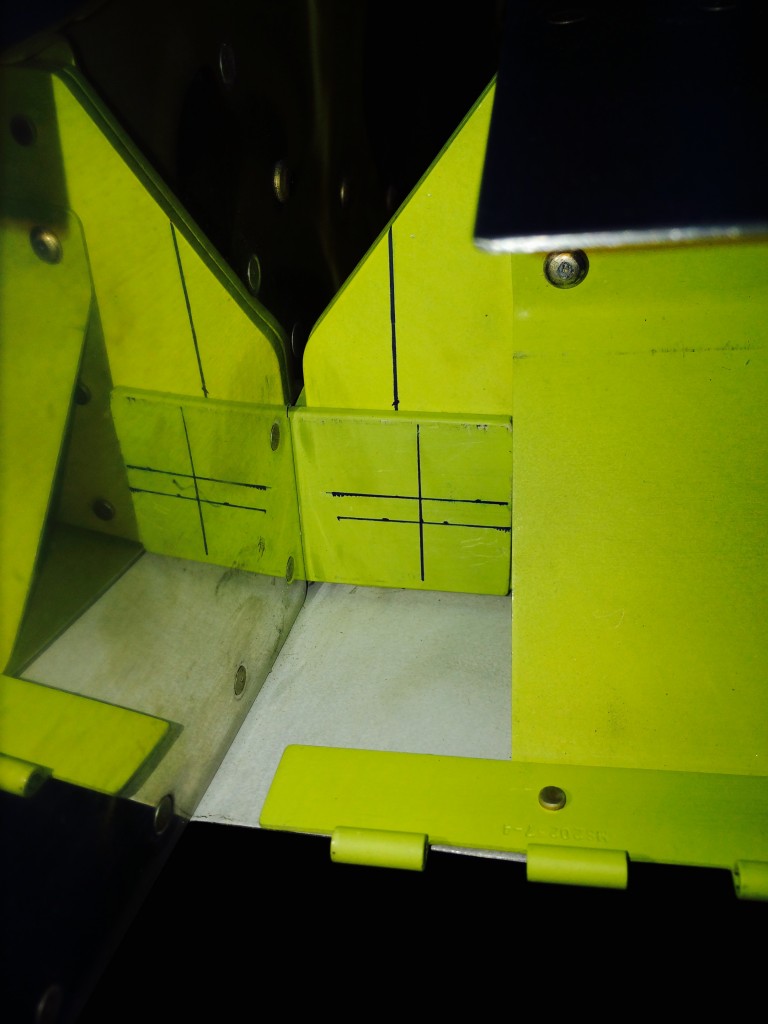

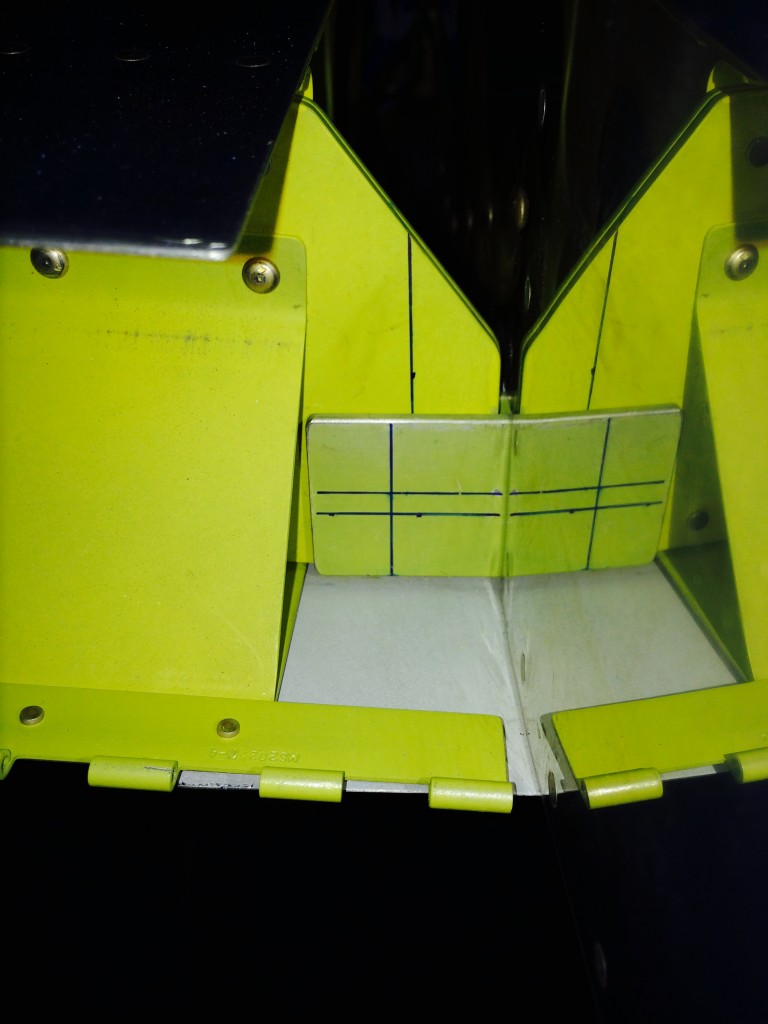

I installed the flaps, and found that the left flap rubbed against the fuselage side skin. The areas outlined in blue are where I had to file off some of the flap skin to eliminate the interference.

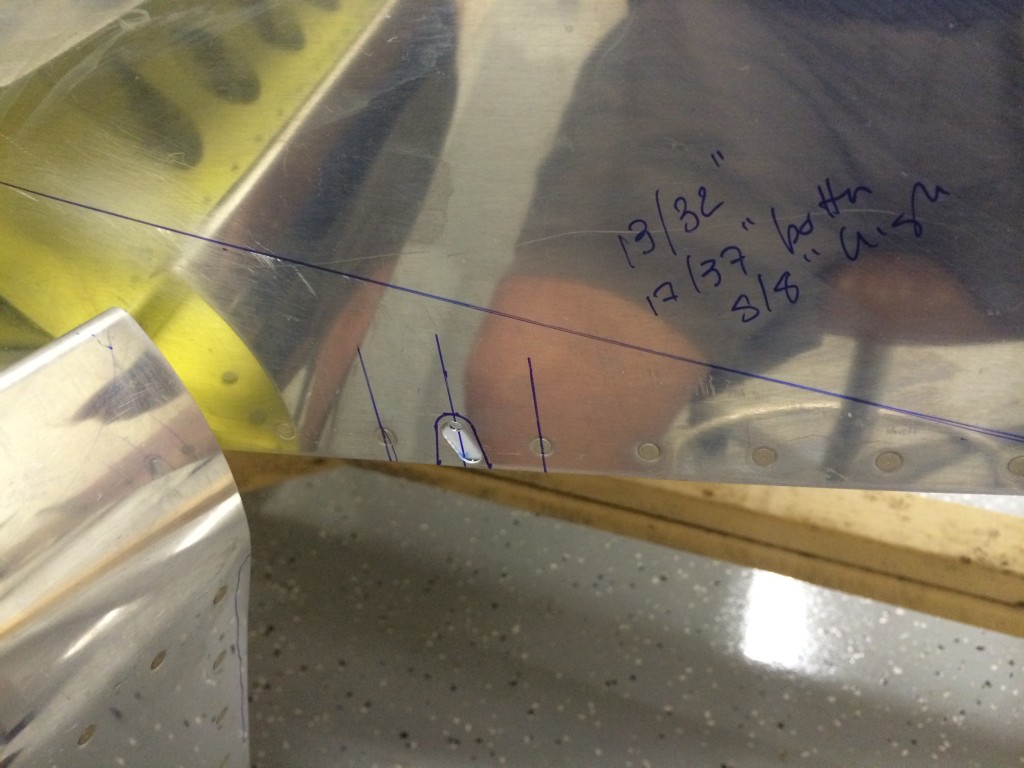

The most tricky part was figuring out exactly how much to enlarge the fuselage side skin openings to accommodate the movement of the flap actuator arms as they move the flaps up and down. Here’s my first guess with some rough measurements roughed out from a friend’s RV-7.

I also laid out holes on the belly skins and started trimming…

This was a very iterative process…move the flaps, check for interference, and trim the holes as appropriate. It took several hours to get the holes for both actuator arms to move freely.

I used my handy Harbor Freight battery booster to run the flap motor…

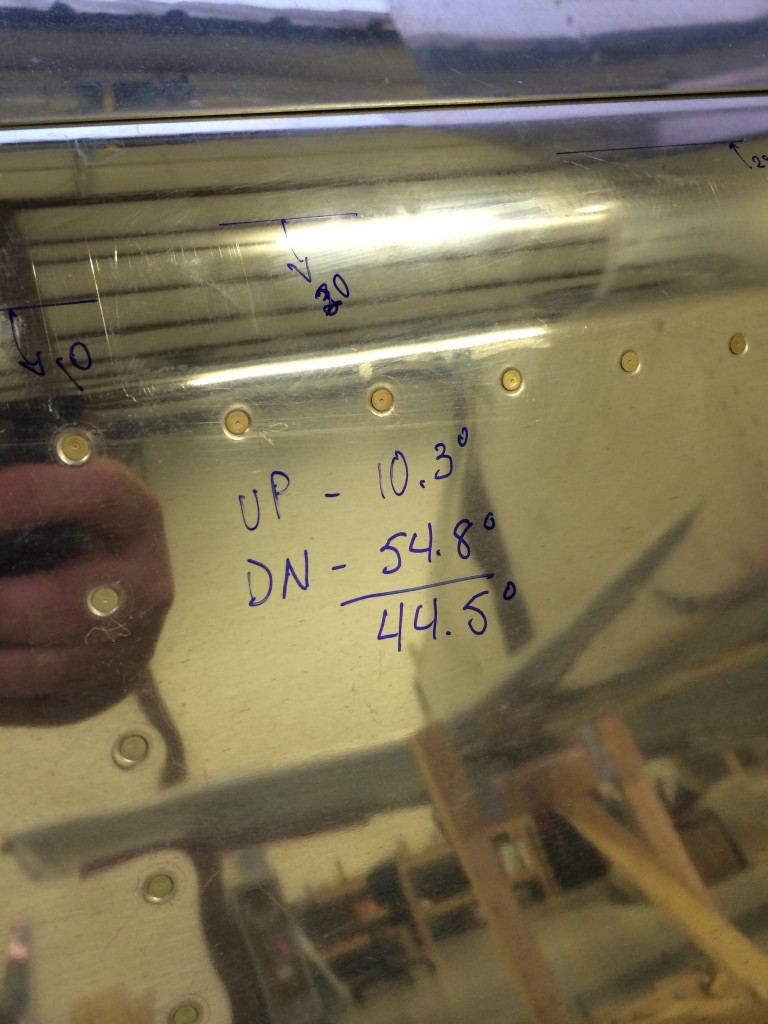

As I was checking the holes for interference, I was also checking for the proper range of flap motion. Vans says the flaps should go down no more than 45 degrees, so used my digital level to measure the flap angle both at full up and full down – subtracting full up from full down shows slightly less than 45 degrees on both sides – perfect!

And here’s the end result on the right flap…looks great!

Rigging the ailerons

Next up on the list of things to be done is rigging the ailerons and aileron pushrods to the control sticks. There’s nothing too difficult here, but like a lot of other tasks at this stage, there’s a lot of tweaking and adjusting involved.

There are two pushrods for each aileron, one from the control stick to a bellcrank in the wing, and another from the bellcrank to the aileron itself. I had already adjusted both bellcrank-to-aileron pushrods when I built the wings, but I wanted to recheck them anyway. So I dug out the bellcrank jig and the fixtures I made to hold the ailerons in trail.

Here’s the fixture that establishes where the trailing edge of the aileron should be…it’s bolted to two tooling holes in the outboard wing rib –

And here’s a couple of pieces of wood I screwed together to hold the aileron itself in place on the fixture. You can see the two lines that define where the trailing edge should be…

Since I already had a pretty good idea that the outboard pushrods were correctly set, I just slipped the bellcrank alignment jig into place and verified that everything was still ok.

Since I already had a pretty good idea that the outboard pushrods were correctly set, I just slipped the bellcrank alignment jig into place and verified that everything was still ok.

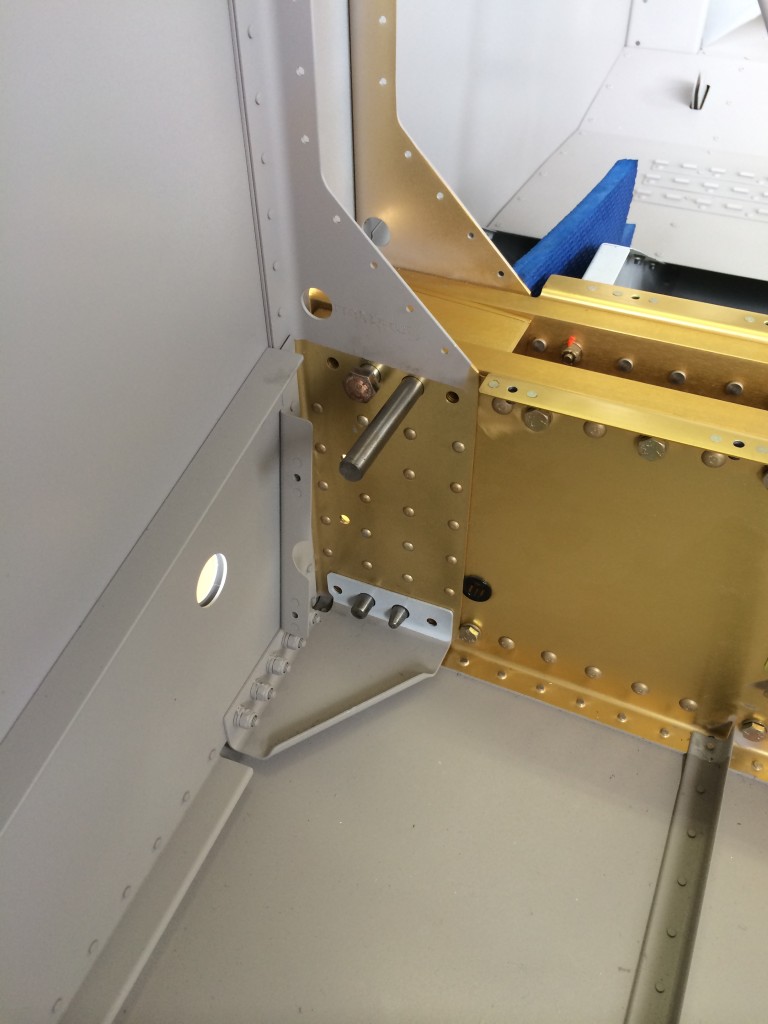

You can’t see the bellcrank jig very well, but it’s the silver piece of metal above the bellcrank itself. It’s placed over a pushrod bolt, and if the jig’s forward edge rests flush against the spar *and* the aileron is aligned in trail, everything is set – which it is here and in the opposite wing.

You can’t see the bellcrank jig very well, but it’s the silver piece of metal above the bellcrank itself. It’s placed over a pushrod bolt, and if the jig’s forward edge rests flush against the spar *and* the aileron is aligned in trail, everything is set – which it is here and in the opposite wing.

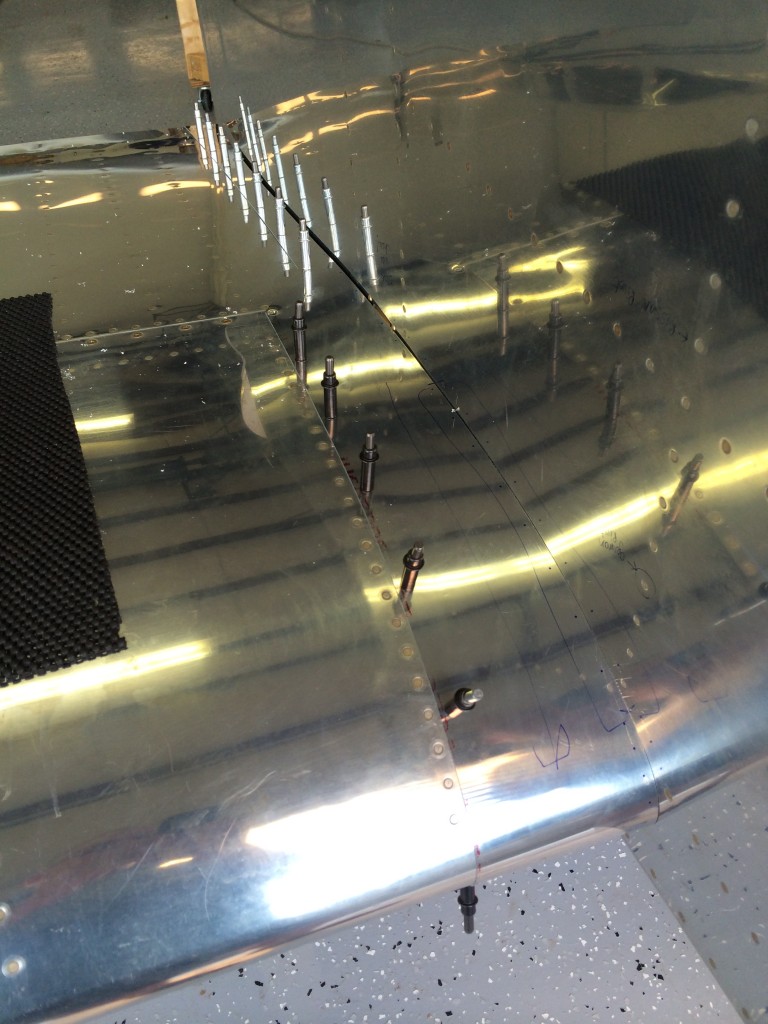

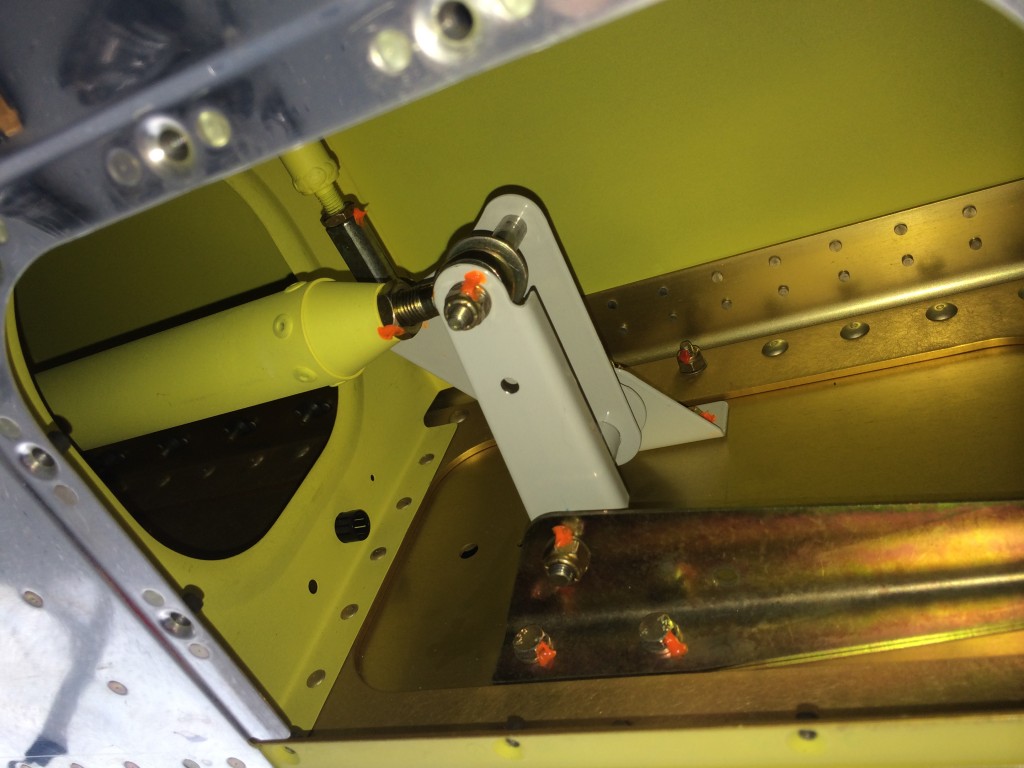

With the ailerons properly in trail, I clamped the control sticks in place so they were vertical (sorry, no pictures) and adjusted the long bellcrank-to-stick pushrods to the proper length. I then went back and torqued all the bellcrank bolts and nuts, as you can see from all the Torque-Seal in the picture.

With the ailerons properly in trail, I clamped the control sticks in place so they were vertical (sorry, no pictures) and adjusted the long bellcrank-to-stick pushrods to the proper length. I then went back and torqued all the bellcrank bolts and nuts, as you can see from all the Torque-Seal in the picture.

It was kinda neat to move the control sticks and see the ailerons move…before the wings come off again I may have to throw a seat in the cockpit and play pilot for a little while!

Wing root fairings and flap rods

I have a whole laundry list of things that need to be done now that the wings are fitted.

First up was fitting the wing root fairings. Nothing too difficult here…the only trick is getting the fairing to conform to the wing leading edge curve enough to get all the holes aligned with those in the wing. A little hand shaping of that area solved the hole alignment problem.

I realized that I made a small mistake several years ago when I built the wings – I match-drilled and dimpled several of the wing skin/rib holes that should have been left undrilled for the fairing attach screws. Looks like I’ll have to drill them out to the right size (#19) and then re-dimple to accept a #8 screw. No big deal.

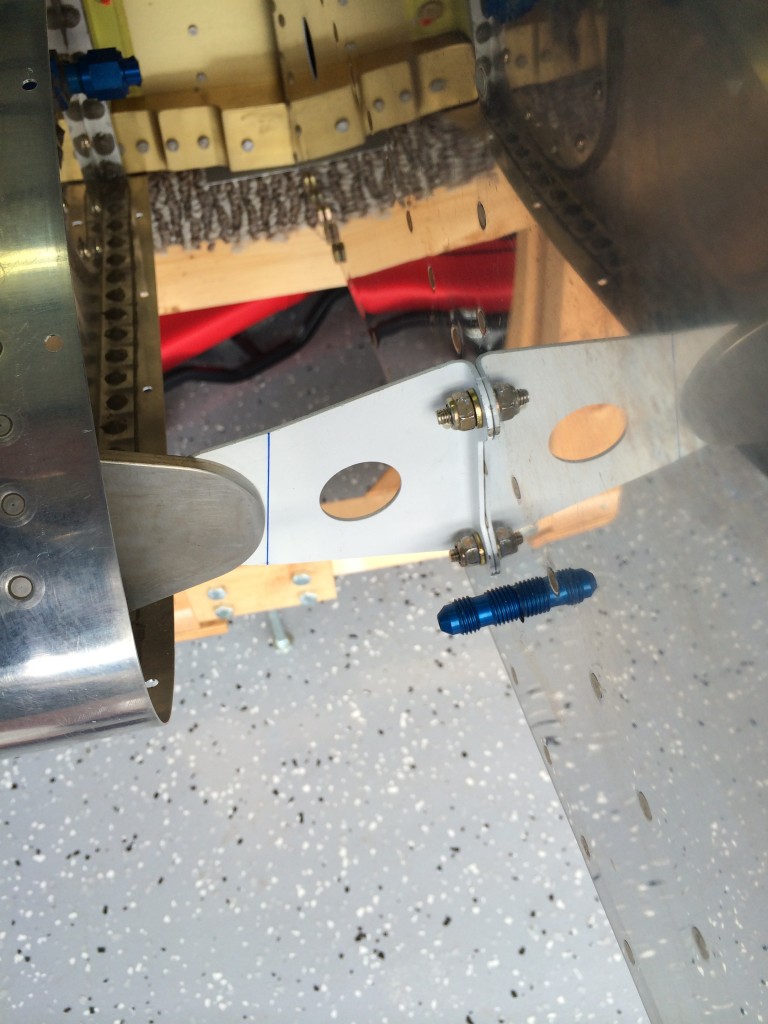

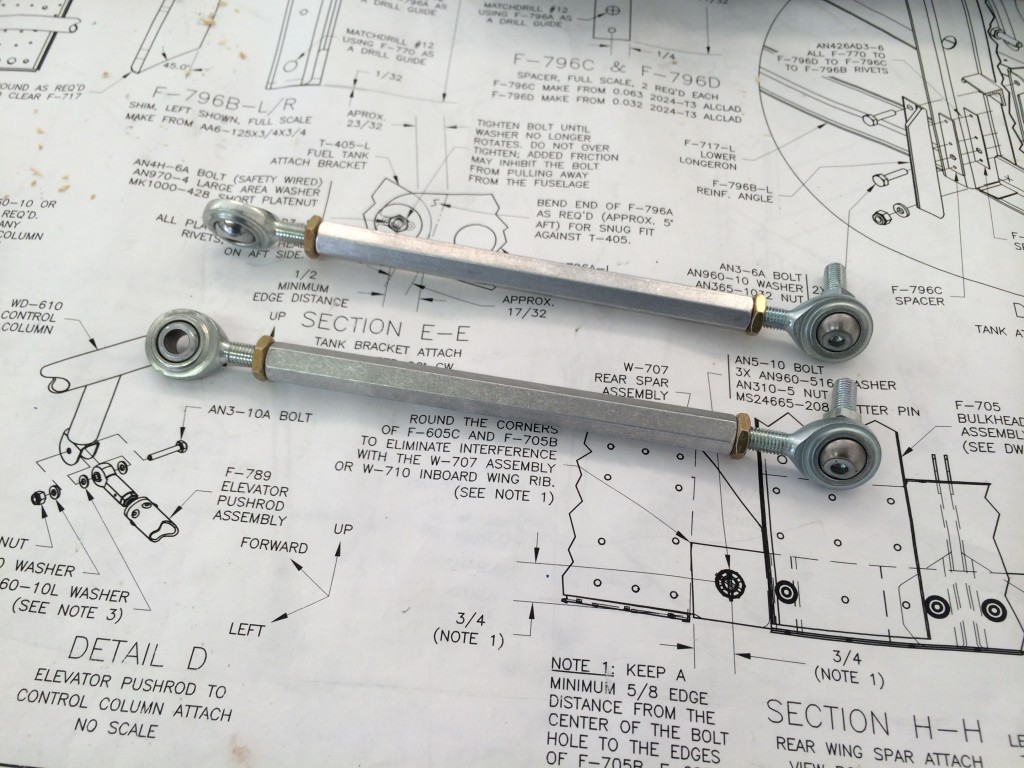

While I was at Oshkosh I bought these spiffy pre-drilled hex flap pushrods rods from Avery Tools. Drilling and tapping a piece of round tube stock for these pushrods per plans is a pain, so these Avery rods save a lot of time and effort…just screw in the rod ends, and you’re done. Cool.

While I was at Oshkosh I bought these spiffy pre-drilled hex flap pushrods rods from Avery Tools. Drilling and tapping a piece of round tube stock for these pushrods per plans is a pain, so these Avery rods save a lot of time and effort…just screw in the rod ends, and you’re done. Cool.

Gotta do it right the first time…

Carrying on from my previous post – there’s one task that RV builders know has to be done right the first time, and that’s drilling the holes in the aft wing spar that set wing sweep and incidence. I’ve already covered all the measurements that verify the wings are in the right position and there’s good edge distance…now it’s time to drill.

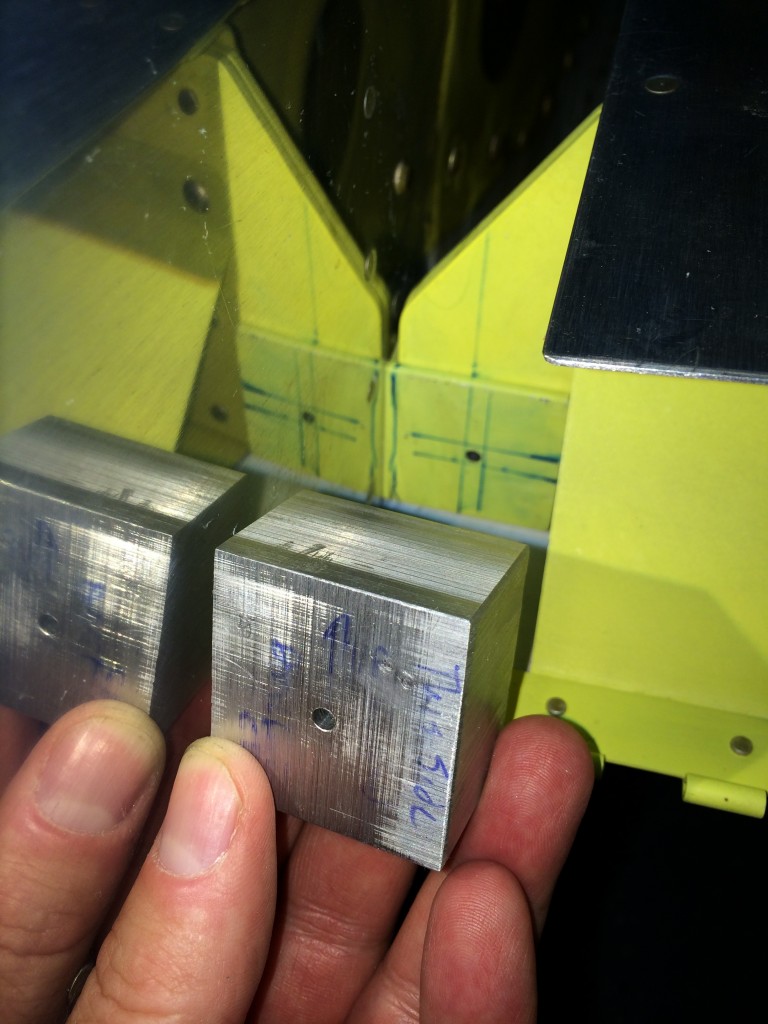

Van’s has a good description of the process on their Construction FAQ page, so I won’t repeat their words here. I found a piece of scrap aluminum bar at a local metal dealer and cut pieces to make drill blocks for #30, 3/16″ and 9/32″ drill bits and one for a 0.311″ reamer – to enlarge the hole in stages. The 9/32″ drill seems like an odd choice, but the ideal use of a reamer is on a hole that’s about 1/32″ undersize – and 9/32″ is just that for the 0.311″ reamer.

The pucker factor was pretty damn high when drilling the #30 pilot holes, but they came out fine –

I then worked up to 3/16″, 9/32″ and 0.311″ and ended up with good holes in each rear spar.

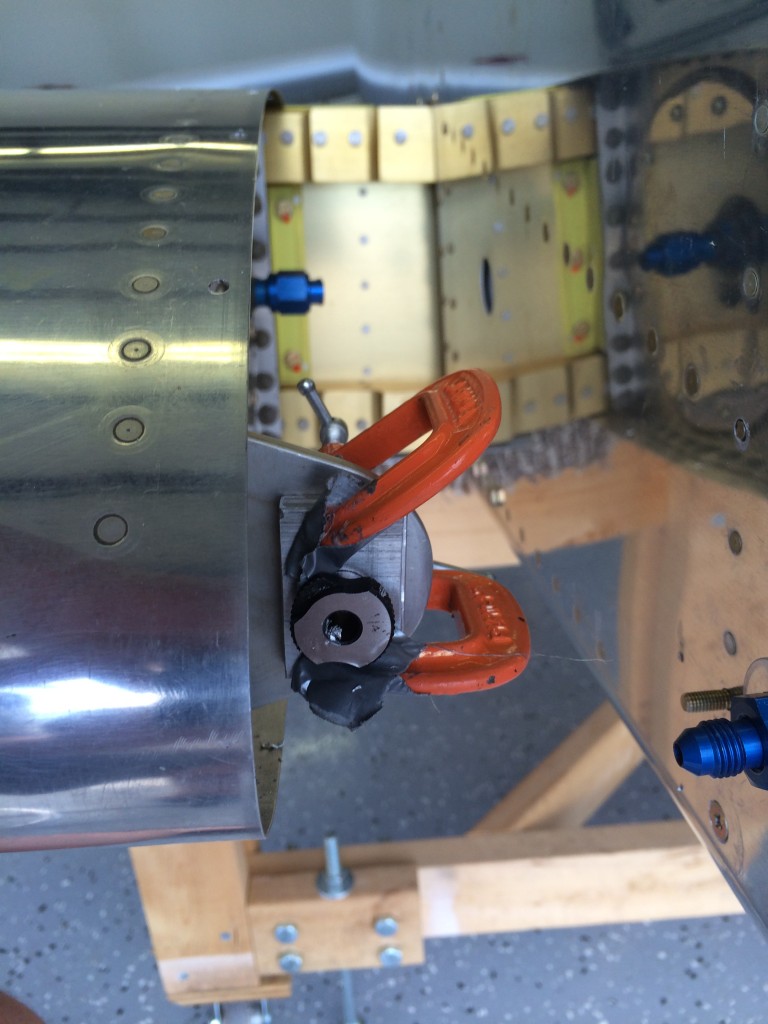

Enlarging to 3/16″ wasn’t too tough, but I was concerned about making sure the 9/32″ drill block was centered – don’t want to eat into the edge distance margin. But then I had a brainwave – insert a long 3/16″ pin punch through the 9/32″ drill block and on into the 3/16″ pilot hole, and continue until the punch’s shank hits the side of the drill block hole, centering it on the 3/16″ hole. Clamp the drill block in place, and voila – the block is centered and ready to use. Here’s the right side –

Here’s the right rear spar, without an AN5 bolt in place…

Here’s the right rear spar, without an AN5 bolt in place…

The drill block process worked really well – finishing the holes with a 0.311″ meant a nice, snug fit for an AN5 bolt – they went in with only a little finger pressure. These bolts are supposed to be be a nominal 5/16″ diameter, but they often run undersize. Had I used a 5/16″ reamer, the bolt fit would have been ok, but probably sloppier than I’d want in this application.

The drill block process worked really well – finishing the holes with a 0.311″ meant a nice, snug fit for an AN5 bolt – they went in with only a little finger pressure. These bolts are supposed to be be a nominal 5/16″ diameter, but they often run undersize. Had I used a 5/16″ reamer, the bolt fit would have been ok, but probably sloppier than I’d want in this application.

So…the rear spars are drilled and it’s a huge relief. I have a backlog of things that need to be done to the wings, like rigging the ailerons and flaps, and it’s time to make some serious forward progress.

Sprouting wings

Food can be effective bribe. Last weekend I bribed Ellen and Whitney, and RV-7 friends Andy Olech and Allison Bailey, with lunch at the Midfield Cafe to help install the wings for the first time. Thanks Andy and Allison, we appreciate you flying up from Hartford and spending the day with us!

And as always, thanks to my family – Ellen and Whits, I couldn’t do any of this without you !

This is one of those times in the project when a lot of past effort to maintain tight tolerances really pays off. Every RV slow-builder stresses about making sure the front and rear spar bulkhead halves in the fuselage are spaced 1.438″ apart as required by the plans. With the help of a little Boelube, the spar ends slid right into the fuselage. Cool.

This is one of those times in the project when a lot of past effort to maintain tight tolerances really pays off. Every RV slow-builder stresses about making sure the front and rear spar bulkhead halves in the fuselage are spaced 1.438″ apart as required by the plans. With the help of a little Boelube, the spar ends slid right into the fuselage. Cool.

With Andy, Allison, Ellen and Whitney adjusting wing position, I inserted a couple of taper pins into bolt holes for each wing. Van’s calls for four pins, so before I made any final measurements and drilled any holes, I borrowed some long, custom-made stainless steel taper pins to augment the four pins I made from hardware-store bolts.

Thanks to Rich Mileika for making those really nice stainless steel taper pins, to John Sannizzaro and Bill Higgins for flying up to Nashua yesterday and helping me get the last 3-4 taper pins in so that the wings are secure, and last but certainly not least, thanks to Bob Weldon and his daughter Emma for muscle power and precision plumb bob stabilization <g>.

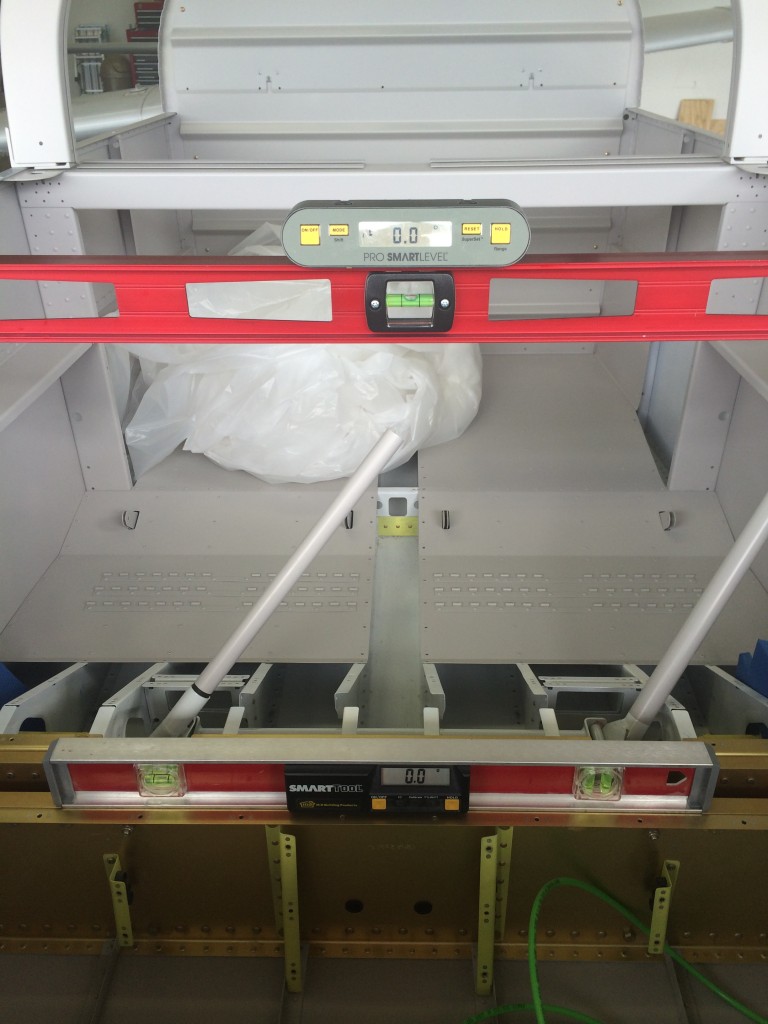

With the wings temporarily installed, I made sure the fuselage was level laterally and longitudinally. The plans call for measuring longitudinal level on the longerons at the cockpit, but these almost always have some residual twist from the bending process that makes it hard to get a good level measurement.

So, I just moved the levels back a few feet to a straight portion of the longerons. I had to adjust the cradle a little to get everything spot on, no big deal.

So, I just moved the levels back a few feet to a straight portion of the longerons. I had to adjust the cradle a little to get everything spot on, no big deal.

According to the Van’s FAQ on wing incidence and sweep, the next measurement is from reference points on each wingtip to a common point on the aft fuselage. My measurements were the same to within 1/32″…cool again.

I then dropped plumb bobs from the wing leading edges – one inboard and one outboard on each wing panel, and laid out a reference line between the outboard plumb bobs to serve as a reference for double-checking sweep. Measuring the distance from the inboard plumb bobs to the reference line, I found that each wing had only 7/32″ of sweep, well within the 1/2″ tolerance that Van’s suggests.

The next measurements check wing angle of incidence. This requires making a simple tool – a carpenter’s level or metal channel with a 3″ spacer on one end. The flat end is placed on the wing skin above the main spar web, and the spacer sits on the skin above the aft spar web. When a level placed on the tool reads zero, the wing has a 1 degree angle of incidence.

The pic above shows the left wing incidence is right on the money. The right wing was the same.

Just for a goof, I checked the angle of incidence at each wingtip…every measurement was within 0.1 degree. This is a real tribute to the quality of Van’s prepunched kits; with reasonable effort, it’s possible to build a nice, straight airplane.

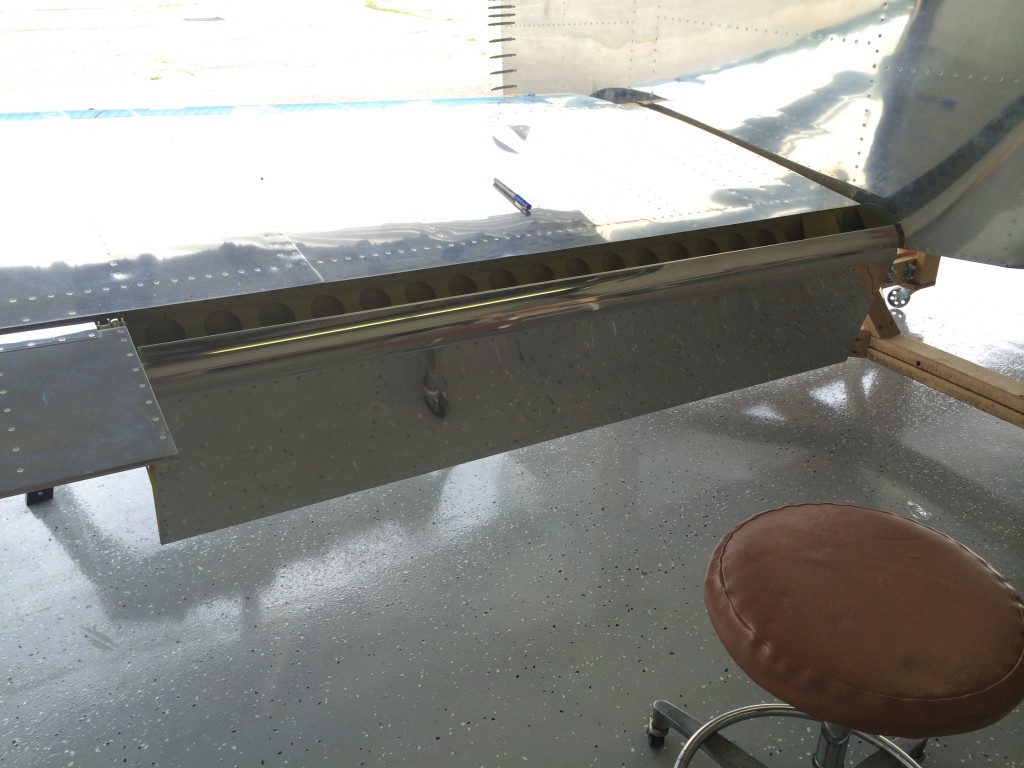

I also test-fitted the flaps to make sure the inboard flap skins fit nicely against the fuselage…

…and it looks like they do.

The last and most critical measurements are edge distance on the rear spar for the hole that accommodates a single attach bolt. I laid out lines on the fuselage and wing spar attachments that represent minimum edge distance from the hole center. As long as there’s distance between the vertical line on the wing spar fitting and the vertical line on the fuselage fitting, there’s sufficient edge distance for a 5/16″ bolt hole.

The right wing looks good…

…and so does the left wing.

I’m not in a rush to drill these holes. They’re one of the few gotta-do-it-right-the-first-time things on the project, and I plan to sneak up on them one step at a time.

More to follow…

Rudder cables and ELT mounts

Over the course of this week I’ve been at the hangar a few times to take care of random stuff prior to mounting the wings.

Before we moved the fuse to the hangar, I installed and secured the rudder/tailwheel steering cables to the tailcone. It would have been good to check the plans and see which end of the cables attach to the rudder control horn (the two ends of the cable aren’t the same), but I neglected to do that. Compounding that mistake, I had already fished the cables through several holes in the tailcone and aft fuse and installed snap-in plastic grommets in those holes that make it impossible to remove the rudder cable once they’re installed. As an extra bonus, the grommets can be installed with access to one side of a hole, but access to both sides of the hole is required to remove them – which is a problem in several places in the tailcone and baggage area where panels are already riveted in place that limit access. D’oh!

Other builders have made this mistake and wound up drilling out rivets and removing panels to get at the grommets, but I was determined not to do that. So…I went on a trek to Home Depot (there’s one about five minutes from the hangar – bonus!) and bought a small propane torch and an X-Acto knife. A red-hot knife slices through plastic pretty easily, and working from one side of the hole, it’s not too hard to slice out the clips that hold the grommets in place. After an hour of heating and cutting, the grommets and the rudder cables were out. 30 minutes later, the rudder cables were installed the right way.

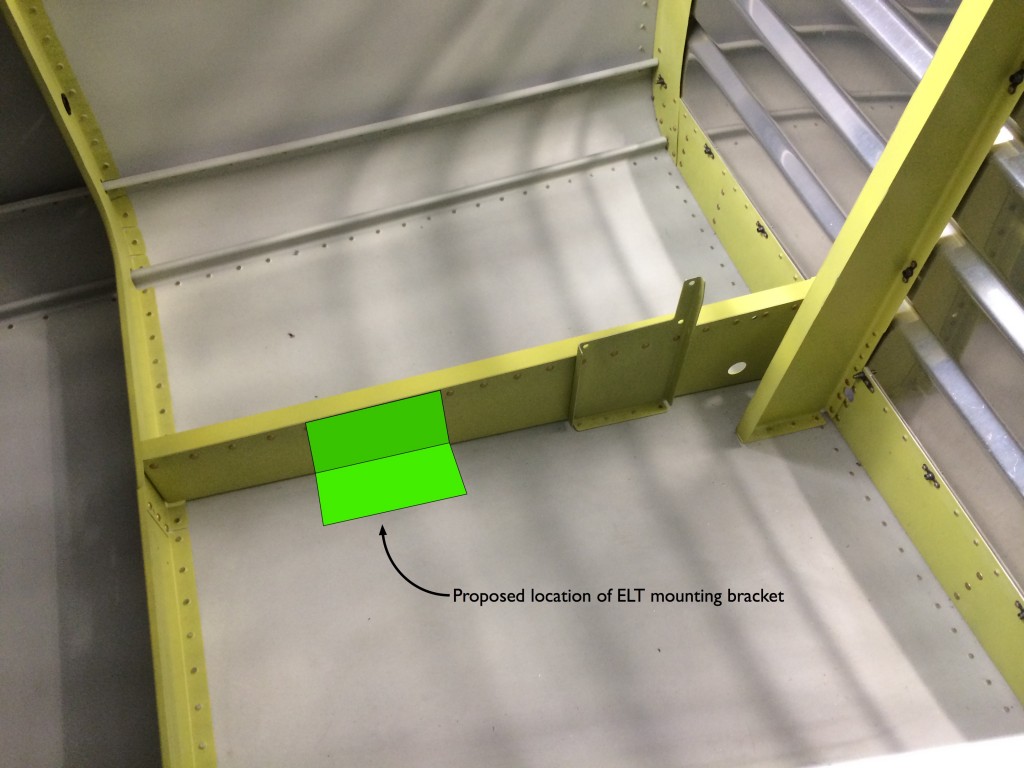

I also started working on the Emergency Locator Transmitter (ELT) mount. Over the last several months I’ve been working out where to install the ELT and have never been very happy with a lot of the options I’ve seen, including Van’s own ELT/strobe mounting plate which seems far too flexible to ensure that the ELT will work when it’s supposed to. Many RV builders regard the ELT as a bureaucratic nuisance and don’t care how it’s installed. They’re certainly free to do as they see fit, but if the device has to be in the airplane, I want it to work as it’s designed to.

My friend Andy mounted his ELT on the horizontal bellcrank rib, which seems like a good place for both longitudinal strength and access for installation, testing and battery changes. The only downside is that the rib doesn’t have a lot of lateral stiffness, and theoretically the ELT mounting surface should withstand a 100-pound pull in any direction without deflecting more than 0.1 inch. I came up withe the idea of fabricating an L-shaped reinforcement plate to provides extra stiffness, and had my fellow FAA DER Tom – who’s a structures engineer – run the numbers to make sure my design would be strong enough while not impacting the existing structure.

It turns out from Tom’s analysis that a piece of 0.040″ 7075-T6 aluminum sheet, bent into the required L-shape, will do the job nicely. It will be held in place on the vertical flange with ELT mounting bolts and the rivets which also attach the bellcrank stiffener angle, and on the horizontal flange with some AN426-3 rivets. Easy peasy! The only downside is that my candy-ass little Harbor Freight bending brake won’t handle 0.040″ 7075 sheet, so I’m gonna have to find someone with the appropriate tools to make the bend. Stay tuned…

It turns out from Tom’s analysis that a piece of 0.040″ 7075-T6 aluminum sheet, bent into the required L-shape, will do the job nicely. It will be held in place on the vertical flange with ELT mounting bolts and the rivets which also attach the bellcrank stiffener angle, and on the horizontal flange with some AN426-3 rivets. Easy peasy! The only downside is that my candy-ass little Harbor Freight bending brake won’t handle 0.040″ 7075 sheet, so I’m gonna have to find someone with the appropriate tools to make the bend. Stay tuned…